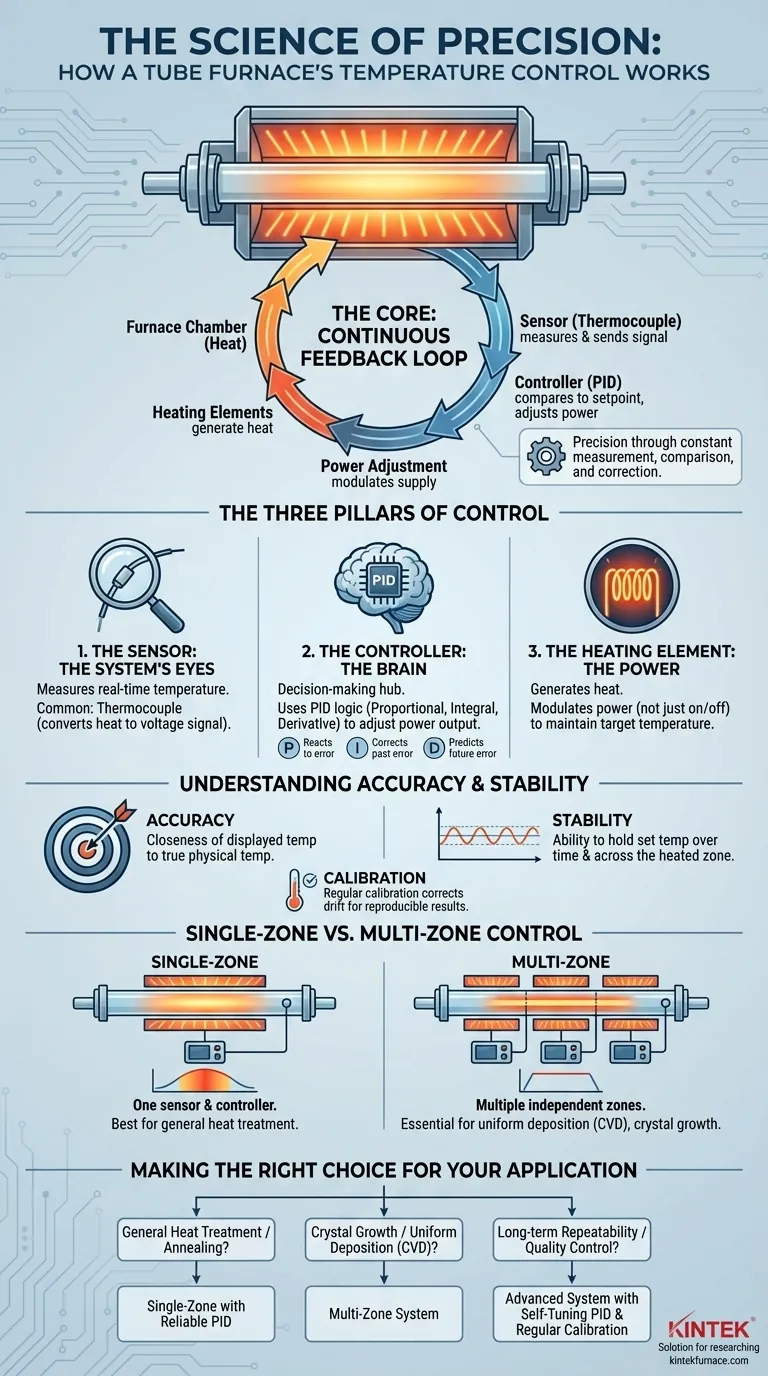

At its core, a tube furnace's temperature control system operates on a continuous feedback loop. A temperature sensor, typically a thermocouple, constantly measures the heat inside the furnace. This measurement is sent to a digital controller, which compares the actual temperature to your desired setpoint and instantly adjusts the power supplied to the heating elements to eliminate any difference.

The precision of a modern tube furnace is not achieved by simply generating heat. It is the result of a relentless cycle of measuring, comparing, and correcting, orchestrated by a smart controller to hold a target temperature with remarkable accuracy.

The Three Pillars of Temperature Control

A high-performance temperature control system is built on three interconnected components working in perfect harmony. Understanding each part demystifies how the furnace achieves such stable and uniform heat.

The Sensor: The System's Eyes

The entire control process begins with an accurate measurement. The system relies on a sensor to report the real-time temperature inside the furnace chamber.

The most common type is a thermocouple, which consists of two different metal wires joined at one end. A temperature change at this junction produces a tiny, predictable voltage that the controller can interpret as a specific temperature.

The Controller: The Brain of the Operation

The controller is the decision-making hub. It takes the temperature signal from the sensor and determines precisely how the heating elements should respond.

Modern furnaces use a PID (Proportional-Integral-Derivative) controller. Think of it like a sophisticated cruise control system for temperature.

- Proportional (P): Reacts to the current temperature error. The further you are from the setpoint, the more power it applies.

- Integral (I): Corrects for past errors. If the temperature consistently sits just below the setpoint, this function gradually adds a bit more power to close the gap.

- Derivative (D): Predicts future errors. It watches how fast the temperature is changing and slows down the heating as it approaches the setpoint to prevent overshooting.

Many advanced systems also feature self-tuning or fuzzy logic, which automatically optimizes these PID values for maximum stability and responsiveness.

The Heating Element: The Source of Power

The heating elements are the components that actually generate the heat. In most lab-scale tube furnaces, these are electrical resistance elements.

When the controller sends a power signal, electricity flows through these elements, causing them to heat up. The controller doesn't just turn them on or off; it modulates the power output, delivering just enough energy to maintain the target temperature as instructed. This heat is then transferred through the furnace chamber to the work tube containing your sample.

Understanding the Trade-offs and Maintaining Accuracy

Achieving and maintaining high performance requires understanding the system's limitations and the importance of proper procedure. Inaccuracies don't just happen; they are introduced through drift, poor setup, or misunderstanding key metrics.

Accuracy vs. Stability

These two terms are not interchangeable. A furnace specification might list a display accuracy of ±1°C and a temperature field stability of ±5°C.

- Accuracy refers to how close the furnace's displayed temperature is to the true, physical temperature at the sensor's location.

- Stability refers to how well the furnace can hold a set temperature over time and across the length of the heated zone. A ±5°C stability means the temperature within the specified "hot zone" will not vary by more than 5 degrees.

The Critical Role of Calibration

Over time, all electronic components, especially thermocouples, can drift. Calibration is the process of correcting this drift to ensure the furnace's readings are true.

This involves placing a separate, highly accurate reference thermometer next to the furnace's sensor, allowing the system to stabilize at several setpoints, and adjusting the controller's internal offsets to match the reference. Regular calibration is non-negotiable for reproducible results.

Single-Zone vs. Multi-Zone Control

A standard single-zone furnace has one sensor, one controller, and one set of heating elements. This is effective for many applications but naturally produces a temperature profile that is hottest in the center and cooler toward the ends of the tube.

A multi-zone furnace divides the tube length into multiple independent heating zones. Each zone has its own thermocouple and controller channel, allowing for a much more uniform temperature profile across a longer section of the tube or even the creation of intentional temperature gradients for processes like chemical vapor deposition (CVD).

Making the Right Choice for Your Application

Your specific goal dictates the level of control you need.

- If your primary focus is general heat treatment or annealing: A standard single-zone furnace with reliable PID control is often sufficient and cost-effective.

- If your primary focus is crystal growth or uniform deposition (CVD): A multi-zone system is essential for creating the precise, stable, and extended hot zones required for these sensitive processes.

- If your primary focus is long-term process repeatability for quality control: Prioritize a system with self-tuning PID capabilities and ensure you have a clear, documented procedure for regular calibration.

Ultimately, understanding this control loop empowers you to not only operate your furnace effectively but also to diagnose issues and select the right instrument for your specific scientific or industrial goals.

Summary Table:

| Component | Function | Key Details |

|---|---|---|

| Sensor | Measures temperature | Typically a thermocouple; converts heat to voltage signal |

| Controller | Adjusts power based on feedback | Uses PID logic for precise, stable temperature control |

| Heating Element | Generates heat | Electrical resistance elements; modulated by controller output |

Ready to enhance your lab's thermal processing with precision? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our tube furnaces can deliver superior temperature control and reliability for your applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis