At its core, a dental porcelain furnace is the critical instrument where scientific precision enables dental artistry. It uses highly controlled technological processes to transform raw ceramic materials into a restoration that is not only strong and durable but also mimics the nuanced beauty of a natural tooth. This fusion of function and aesthetics is what makes it an indispensable tool in modern restorative dentistry.

The furnace's true value lies in providing a perfectly controlled environment. This technological stability gives the dental technician the reliable canvas they need to apply their artistic skill and create a lifelike, aesthetically pleasing result.

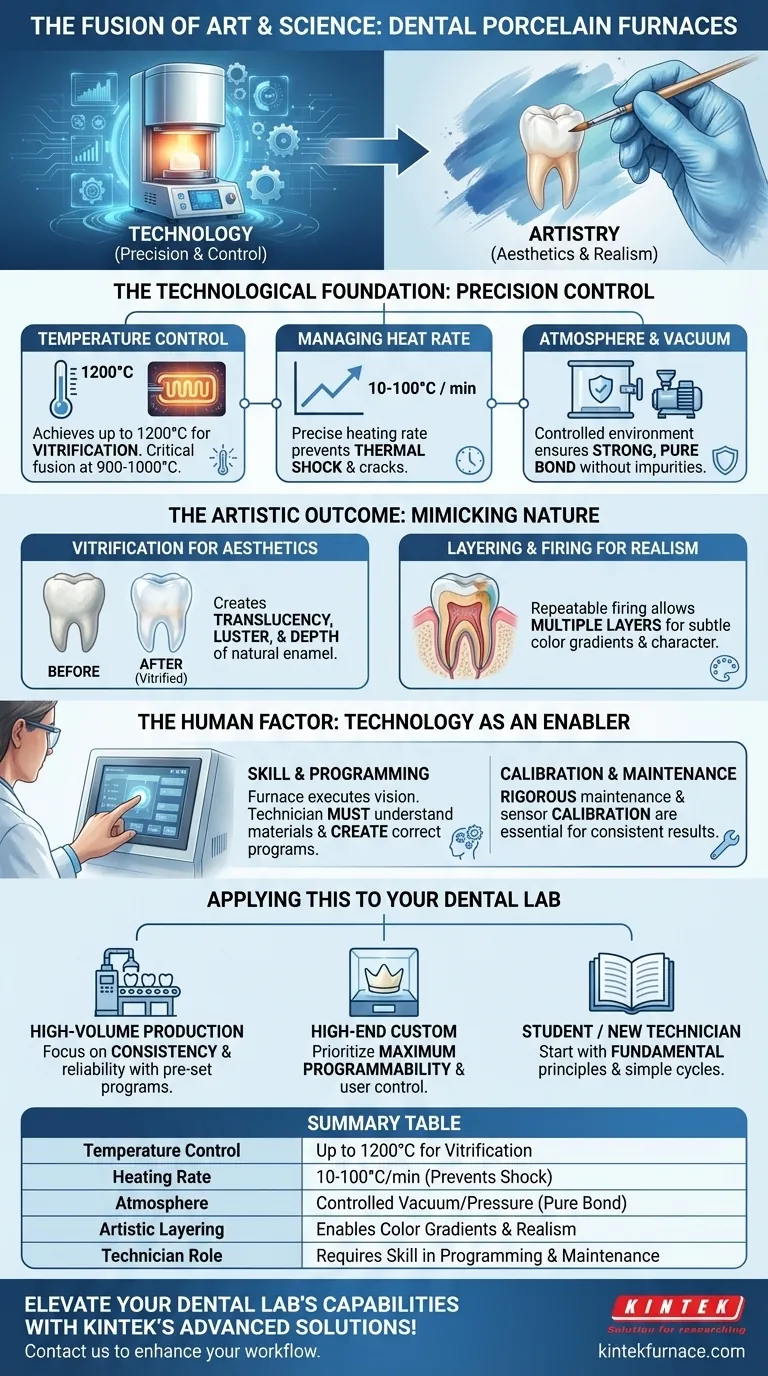

The Technological Foundation: Precision Control

The furnace is far more than a simple oven. It is a precision instrument designed to manipulate materials at a microscopic level through the exact application of heat in a controlled environment.

The Role of Temperature Control

The furnace’s primary function is to achieve and maintain extremely precise temperatures, often reaching up to 1200°C.

This control is critical for vitrification, the process that transforms granular porcelain powder into a dense, glass-like substance. It also allows for the perfect fusion of porcelain to underlying metal or zirconia substrates at specific temperatures, typically between 900-1000°C.

Managing Heat Rate and Atmosphere

The speed at which the temperature changes is just as important as the final temperature itself. The furnace manages the heating rate with incredible accuracy, usually between 10 to 100°C per minute.

This prevents thermal shock, which can cause cracks and compromise the structural integrity of the restoration. The entire process takes place within a sealed chamber, creating a controlled vacuum or atmospheric pressure that ensures a strong, pure bond without impurities.

The Artistic Outcome: Mimicking Nature

The technological precision of the furnace is not an end in itself; it is the means to an artistic end. Every controlled parameter is designed to help the technician replicate the subtleties of a natural tooth.

Achieving Vitrification for Aesthetics

Vitrification is the key to porcelain's aesthetic success. The resulting glass-like state gives the final restoration the translucency, luster, and depth of natural tooth enamel.

Without the furnace's ability to precisely manage this transformation, the material would appear opaque, chalky, and lifeless.

Layering and Firing for Realism

A dental technician's artistry is most evident in the layering process. They apply multiple, thin layers of different shades and opacities of porcelain to build up the tooth's final form.

The furnace's repeatable and accurate firing cycles allow the technician to fuse each layer perfectly without disturbing the layers beneath. This is how they create the subtle color gradients and internal character that make a crown indistinguishable from a real tooth.

Understanding the Trade-offs: The Human Factor

While the technology is powerful, it is a tool that enhances—rather than replaces—the skill of the technician. The furnace and the artist exist in a symbiotic relationship.

Technology as an Enabler, Not a Replacement

An advanced furnace cannot compensate for a poor understanding of tooth morphology or color science. The final aesthetic quality is a direct result of the technician's hand-shaping, color-matching, and layering skills. The furnace simply executes their artistic vision with precision.

The Critical Role of Programming

Mastering a dental furnace requires significant training. The technician must understand how different porcelain systems react to heat and select or create the correct firing program for each specific case. An incorrect program can easily ruin a meticulously crafted restoration.

Calibration and Maintenance

The furnace's precision depends on rigorous and consistent maintenance. If the temperature sensor (thermocouple) is not calibrated correctly, the displayed temperature will not match the actual chamber temperature, leading to under-fired or over-fired restorations that fail both structurally and aesthetically.

Applying This to Your Dental Lab

Your approach should be guided by the specific goals of your laboratory and the skill of your technicians.

- If your primary focus is consistency and high-volume production: Invest in a furnace with proven, pre-set programs for common materials and a reputation for reliability to minimize variations.

- If your primary focus is high-end, custom aesthetic restorations: Prioritize a furnace that offers maximum programmability and user control, allowing your master technicians to fine-tune every parameter.

- If you are a student or new technician: Focus first on the fundamental principles of how time and temperature affect porcelain, using simple programs before moving to complex custom cycles.

Ultimately, the dental furnace is the essential bridge that connects the objective science of materials with the subjective art of creating a beautiful smile.

Summary Table:

| Aspect | Key Details |

|---|---|

| Temperature Control | Achieves up to 1200°C for vitrification and fusion (900-1000°C) |

| Heating Rate | 10-100°C per minute to prevent thermal shock |

| Atmosphere | Controlled vacuum or pressure for pure bonding |

| Artistic Layering | Allows multiple porcelain layers for color gradients and realism |

| Technician Role | Requires skill in programming, color-matching, and maintenance |

Elevate your dental lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Whether you're focused on high-volume production or custom aesthetic restorations, our precision tools ensure reliable, lifelike results. Contact us today to discuss how we can enhance your restorative dentistry workflow and deliver superior value!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations