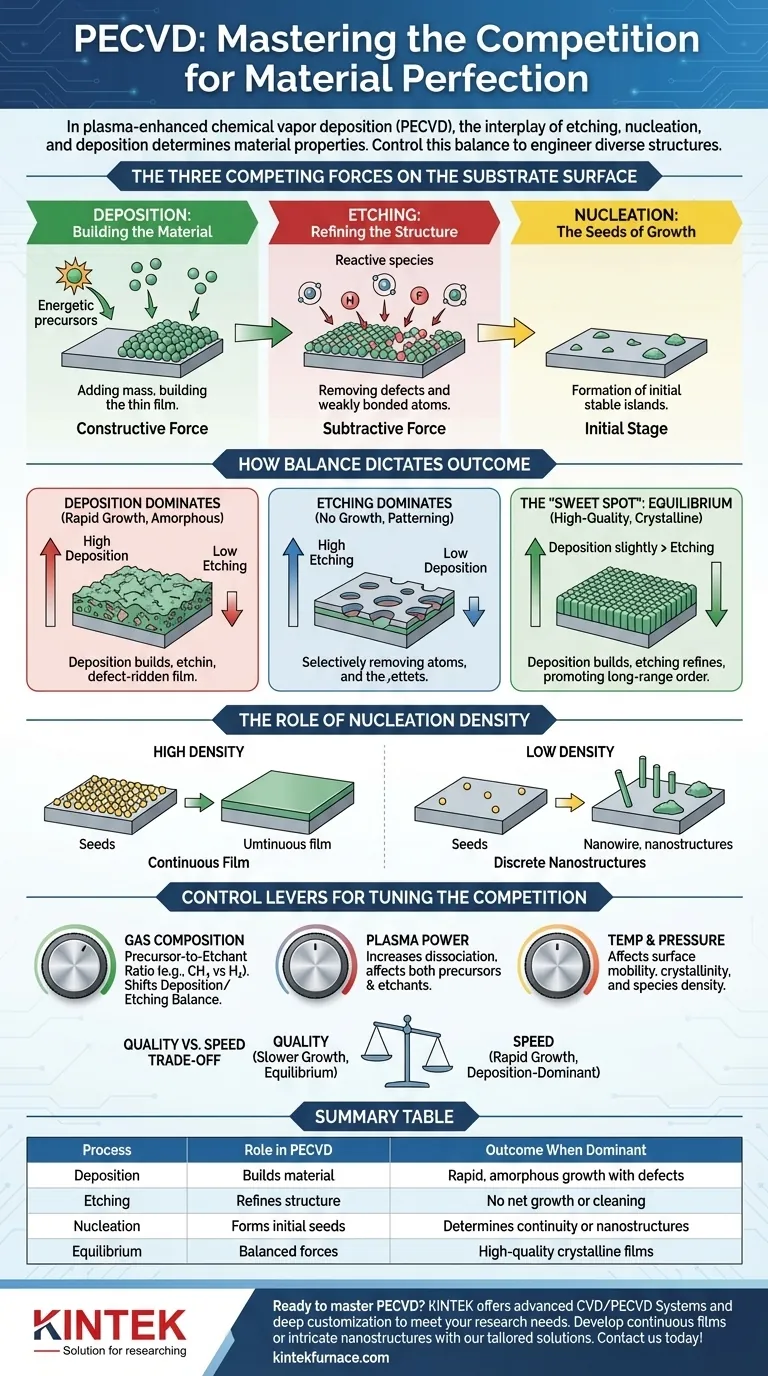

In plasma-enhanced chemical vapor deposition (PECVD), the simultaneous competition between etching, nucleation, and deposition is the fundamental mechanism that enables precise control over material preparation. This dynamic balance is not a flaw in the process; it is the very feature that allows for the creation of materials with diverse, tailored morphologies and properties, from continuous films to intricate nanostructures.

The final outcome of a PECVD process is determined by the delicate balance between adding material (deposition), removing it (etching), and initiating its growth (nucleation). Mastering PECVD means learning how to intentionally shift this balance to achieve a specific material structure.

The Three Competing Forces in PECVD

To control the outcome of a PECVD process, you must first understand the three core actions that are constantly at war with each other on the substrate surface.

### Deposition: Building the Material

Deposition is the primary growth mechanism. Energetic and reactive chemical precursors from the plasma land on the substrate and bond to it, adding mass and building the thin film layer by layer. This is the constructive force in the system.

### Etching: Refining the Structure

Simultaneously, other reactive species in the plasma—often atomic hydrogen or fluorine—act as etchants. They bombard the growing film and selectively remove weakly bonded atoms, amorphous phases, or misaligned crystals. This subtractive force purifies the material and helps define its structure.

### Nucleation: The Seeds of Growth

Before significant deposition can occur, the process must begin with nucleation. This is the formation of the first stable, tiny islands of material on the substrate. The density and distribution of these initial nuclei are critical; they dictate whether the film will grow as a continuous sheet or as a collection of separate structures.

How the Balance Dictates the Outcome

The final morphology of the material is a direct result of which of these three processes is dominant at any given moment.

### When Deposition Dominates

If the deposition rate far outpaces the etching rate, growth is rapid. This can be useful for creating thick, amorphous films quickly. However, without the refining action of etching, the resulting material often has more defects and a less-ordered crystalline structure.

### When Etching Dominates

If the etching rate is greater than the deposition rate, no net film growth will occur. In extreme cases, the plasma will begin to etch the substrate itself. This regime is only desirable when the goal is to pattern or clean a surface, not to grow a film.

### The "Sweet Spot": Deposition-Etching Equilibrium

The key to growing high-quality crystalline films lies in finding a state of near-equilibrium. Here, the deposition rate is only slightly higher than the etching rate. Deposition builds the crystal lattice, while the constant etching "cleans up" any atoms that don't land in the correct spot, removing defects and promoting long-range order.

### The Role of Nucleation Density

The initial nucleation phase sets the stage for the final morphology.

- High Nucleation Density: Many seeds form close together, leading them to quickly merge (coalesce) into a uniform, continuous film.

- Low Nucleation Density: Fewer, widely-spaced seeds form, allowing each one to grow into a distinct, isolated structure like a nanowire, nanodisk, or vertical graphene sheet before it touches its neighbor.

Understanding the Trade-offs and Control Parameters

Your ability to control the PECVD process hinges on your ability to manipulate the parameters that shift the balance between these competing forces.

### Control Lever: Gas Composition

This is the most direct lever. The ratio of precursor gas (e.g., methane for carbon growth) to etchant gas (e.g., hydrogen) directly controls the deposition-vs-etching balance. More precursor favors deposition; more etchant favors etching.

### Control Lever: Plasma Power

Increasing plasma power generally increases the dissociation of all gases, creating more precursors and more etchants. This can accelerate both deposition and etching, and its net effect is highly dependent on the specific gas chemistry and pressure.

### Control Lever: Temperature and Pressure

Higher substrate temperatures provide atoms with more surface mobility, helping them find their ideal lattice sites and promoting crystallinity. System pressure affects the density and energy of the plasma species, altering the dominant reactions in the chamber.

### The Quality vs. Speed Trade-off

There is an inherent trade-off. Conditions that favor extremely high-quality crystalline materials (a finely-tuned deposition-etching balance) often require slower growth rates. Conversely, achieving rapid growth usually requires a deposition-dominant regime, which can sacrifice crystalline quality.

Tuning the Competition for Your Goal

Use your understanding of this dynamic competition to achieve your specific material synthesis objective.

- If your primary focus is high-quality, continuous crystalline films: Your goal is a delicate equilibrium where the deposition rate is just slightly higher than the etching rate to allow for defect removal.

- If your primary focus is rapid, amorphous film growth: You should operate in a deposition-dominant regime by increasing the precursor-to-etchant gas ratio.

- If your primary focus is creating discrete nanostructures (e.g., nanowires, islands): You must control the initial nucleation phase to achieve a low density of nucleation sites, allowing structures to grow separately.

- If your primary focus is material patterning or surface cleaning: You must intentionally create an etching-dominant regime by using a high concentration of etchant gas and minimal or no precursor gas.

By viewing these competing forces as controllable levers, you can transform the PECVD process from a complex challenge into a precise tool for materials engineering.

Summary Table:

| Process | Role in PECVD | Outcome When Dominant |

|---|---|---|

| Deposition | Builds material by adding atoms | Rapid growth, often amorphous with defects |

| Etching | Refines structure by removing atoms | No net growth or surface cleaning |

| Nucleation | Forms initial growth seeds | Determines film continuity or nanostructure formation |

| Equilibrium | Balanced deposition and etching | High-quality crystalline films with defect removal |

Ready to master PECVD for your material synthesis? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, whether you're developing continuous films or intricate nanostructures. Contact us today to discuss how our tailored solutions can enhance your lab's efficiency and achieve superior material outcomes!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the microarc produced by ion discharge function? Enhance Coating Bonding Strength via Surface Activation

- What are the advantages of using PECVD over other deposition methods? Unlock Low-Temp, High-Speed Film Deposition

- What frequencies are used to excite capacitive discharges in PECVD? Optimize Your Thin Film Deposition Process

- What is the process for creating diamond-like carbon (DLC) coatings using PECVD? Master Low-Temperature, High-Performance Coatings

- What are the advantages of using PECVD? Unlock Low-Temp, High-Quality Thin Film Deposition

- What role does PECVD play in solar cell production? Boost Efficiency with Advanced Thin-Film Deposition

- How does PECVD compare to LPCVD? Choose the Right CVD Method for Your Lab

- What types of PECVD systems are available? Find the Perfect Fit for Your Lab's Needs