Precise temperature control in crucible furnaces is a critical operational benefit that directly translates to higher quality products and reduced material waste. It ensures that materials are not just melted, but are processed under exact thermal conditions, which is essential for achieving specific, repeatable metallurgical properties in the final product.

The core value of temperature control extends far beyond simply reaching a melting point. It is the primary tool for dictating a material's final characteristics, ensuring consistency, and preventing costly defects that arise from thermal instability.

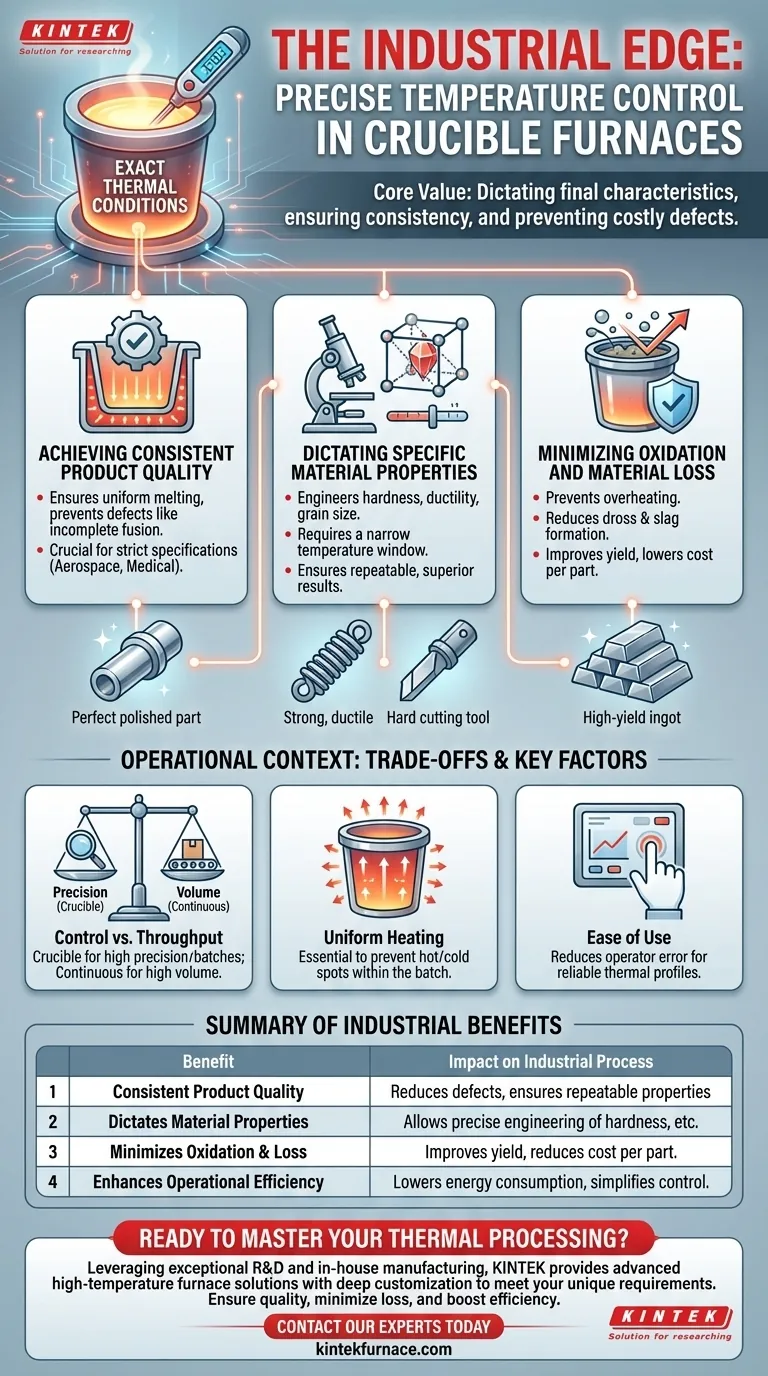

Why Precise Temperature Matters

The ability to accurately manage heat is the difference between basic melting and advanced material processing. It influences every stage of the operation, from energy consumption to the structural integrity of the final cast part.

Achieving Consistent Product Quality

The most significant benefit is the direct impact on quality. Inconsistent heating leads to inconsistent results, creating defects and compromising the material's intended performance.

Precise control ensures that the entire melt reaches and maintains a uniform temperature, preventing issues like incomplete fusion, segregation of alloys, or the formation of undesirable microstructures.

This consistency is crucial for industries where parts must meet strict specifications, such as aerospace, medical, or automotive manufacturing.

Dictating Specific Material Properties

Temperature is a lever for engineering specific material outcomes. The exact temperature at which a metal is held, and the rate at-which it cools, determines properties like hardness, ductility, and grain size.

For many alloys, a narrow temperature window is required to achieve the desired phase and structure. Deviating even slightly can result in a completely different, and often inferior, material.

Crucible furnaces with advanced controls allow operators to reliably produce materials with these exact characteristics, batch after batch.

Minimizing Oxidation and Material Loss

Overheating is a common and costly problem. When a molten metal is heated significantly above its liquidus temperature, the rate of oxidation increases dramatically.

This oxidation results in the formation of dross and slag, which is a direct loss of valuable metal and can introduce impurities into the melt.

By maintaining the temperature just above the required point, precise control minimizes these oxidation losses, improving yield and reducing the cost per part.

Understanding the Operational Context

While temperature control is a defining feature, it's important to understand it in the context of other operational factors and trade-offs.

Control vs. Throughput

Crucible furnaces excel at providing tight temperature control for small-to-medium-sized batches. This makes them ideal for applications requiring high precision or frequent alloy changes.

However, for mass production of a single material, a continuous furnace might be chosen for its higher throughput, even if it offers slightly less granular control over individual batches. The choice depends on whether precision or volume is the primary driver.

The Role of Uniform Heating

Accurate temperature measurement is only half the battle. The furnace must also provide uniform heating to ensure there are no hot or cold spots within the crucible.

Modern crucible furnaces are designed to distribute heat evenly, ensuring the entire volume of molten material is at the same temperature. This prevents inconsistencies within a single batch.

The Link to Ease of Use

The references highlight that crucible furnaces are often easy to operate. This simplicity directly supports temperature accuracy.

An intuitive control system reduces the risk of operator error, ensuring the correct thermal profiles are programmed and executed reliably. This minimizes variables and contributes to a more stable, predictable process.

Making the Right Choice for Your Goal

To apply this knowledge, consider how temperature control aligns with your primary industrial objective.

- If your primary focus is high-value alloys or R&D: The non-negotiable precision of a crucible furnace protects your investment by preventing material loss and ensuring repeatable, accurate results.

- If your primary focus is consistent production quality: Direct temperature control is your best tool for reducing scrap rates and ensuring every component meets its required performance specifications.

- If your primary focus is operational efficiency: Exact temperature management minimizes energy waste from overheating and improves your yield by reducing material loss to oxidation.

Ultimately, mastering temperature control transforms melting from a simple phase change into a predictable and highly refined engineering process.

Summary Table:

| Benefit | Impact on Industrial Process |

|---|---|

| Consistent Product Quality | Reduces defects and ensures repeatable metallurgical properties. |

| Dictates Material Properties | Allows precise engineering of hardness, ductility, and grain size. |

| Minimizes Oxidation & Loss | Improves yield and reduces cost per part by preventing overheating. |

| Enhances Operational Efficiency | Lowers energy consumption and simplifies process control. |

Ready to Master Your Thermal Processing?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and foundries with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Crucible Furnaces, is complemented by our strong deep customization capability to precisely meet your unique thermal processing requirements. Ensure superior product quality, minimize material loss, and boost your operational efficiency.

Contact our experts today to discuss how a KINTEK furnace can transform your industrial process.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications