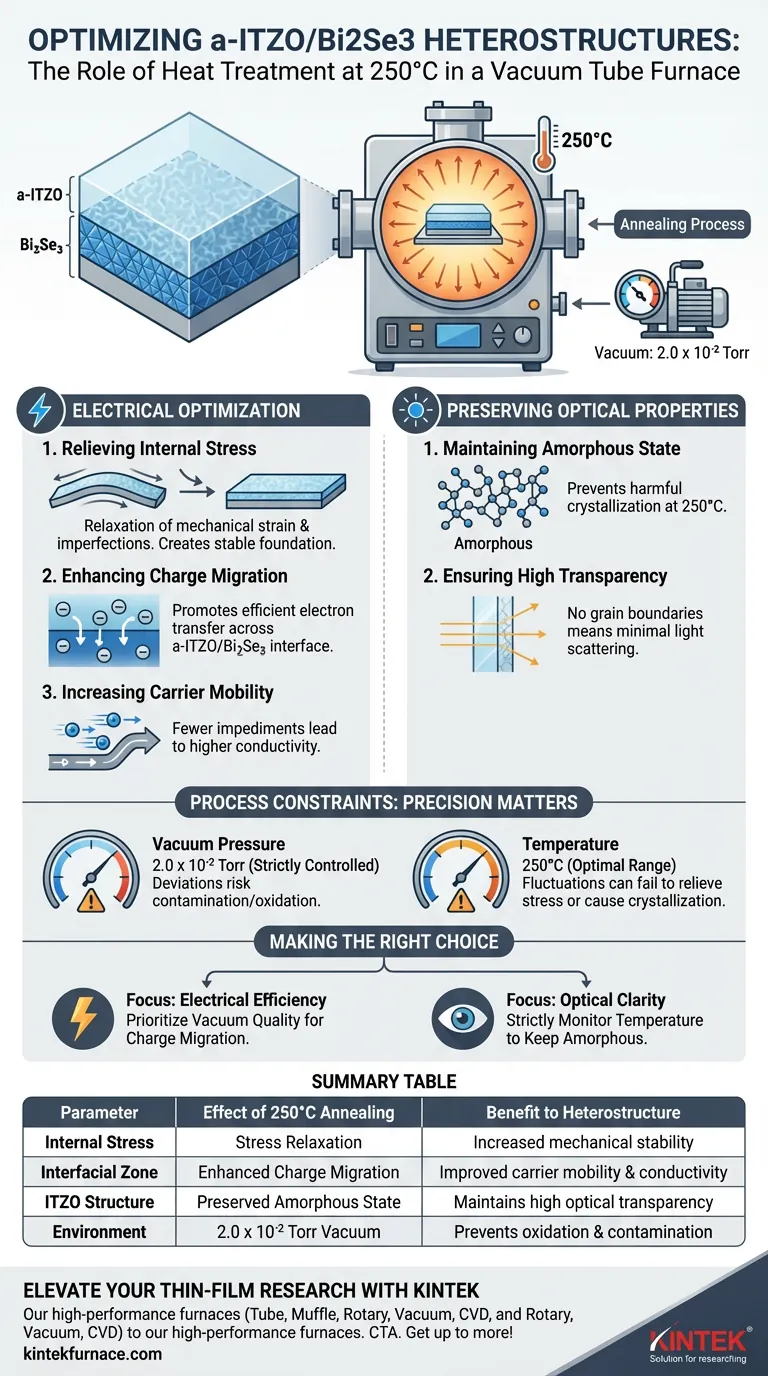

Heat treatment at 250°C in a vacuum tube furnace serves as a critical stabilization step for optimizing a-ITZO/Bi2Se3 heterostructures. Under a specific vacuum environment of 2.0 x 10^-2 Torr, this annealing process relieves internal deposition stresses and enhances interfacial charge transfer, resulting in superior conductivity without compromising optical transparency.

The annealing process fundamentally balances structural integrity with electrical efficiency. It maximizes carrier mobility by refining the interface while preserving the amorphous nature of the ITZO layer to ensure the device remains transparent.

Mechanisms of Electrical Optimization

Relieving Internal Stress

Deposition processes often introduce mechanical strain and structural imperfections within material layers.

Annealing at 250°C effectively relaxes these internal stresses, creating a more mechanically stable foundation for the device.

Enhancing Charge Migration

The interface between the a-ITZO and Bi2Se3 layers is the critical zone for device performance.

Heat treatment promotes efficient charge migration across this boundary, which is essential for the heterostructure's overall functionality.

Increasing Carrier Mobility

With improved interfacial contact and reduced mechanical stress, charge carriers encounter fewer impediments.

This leads to a significant increase in carrier mobility and conductivity, directly translating to higher electrical performance.

Preserving Optical Properties

Maintaining the Amorphous State

In many conductive oxides, high temperatures can induce crystallization, which alters material properties.

Crucially, this specific thermal treatment at 250°C maintains the amorphous state of the ITZO layer.

Ensuring High Transparency

By preventing crystallization, the material avoids forming grain boundaries that typically scatter light.

This preservation of the amorphous structure ensures the heterostructure retains high transparency, a mandatory requirement for optoelectronic applications.

Understanding the Process Constraints

Precision of Process Conditions

The success of this optimization relies heavily on the specific environmental parameters.

The vacuum pressure of 2.0 x 10^-2 Torr must be strictly controlled; deviations could introduce contaminants or oxidation that degrade the interface.

Temperature Limitations

While 250°C is optimal, significant fluctuations in temperature can lead to diminishing returns.

Temperatures that are too low may fail to relieve stress, while excessive heat risks crystallizing the ITZO, which would ruin the optical transparency.

Making the Right Choice for Your Goal

To replicate this performance in fabrication, you must balance electrical gains with structural preservation.

- If your primary focus is electrical efficiency: Prioritize the quality of the vacuum environment to maximize charge migration and carrier mobility at the interface.

- If your primary focus is optical clarity: Strictly monitor the annealing temperature to ensure the ITZO layer remains amorphous and transparent.

Precise control of the annealing environment is the key to unlocking the full potential of this heterostructure.

Summary Table:

| Parameter | Effect of 250°C Annealing | Benefit to Heterostructure |

|---|---|---|

| Internal Stress | Stress Relaxation | Increased mechanical stability |

| Interfacial Zone | Enhanced Charge Migration | Improved carrier mobility and conductivity |

| ITZO Structure | Preserved Amorphous State | Maintains high optical transparency |

| Environment | 2.0 x 10^-2 Torr Vacuum | Prevents oxidation and contamination |

Elevate Your Thin-Film Research with KINTEK

Precision is non-negotiable when optimizing advanced heterostructures like a-ITZO/Bi2Se3. KINTEK provides industry-leading thermal solutions designed for rigorous research and production standards. Backed by expert R&D and manufacturing, we offer high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific vacuum and temperature requirements.

Ready to achieve superior material properties? Contact KINTEK today to discover how our lab high-temp furnaces can bring unparalleled control to your annealing processes.

Visual Guide

References

- Chih-Chiang Wang, He-Ting Tsai. Enhanced electrical properties of amorphous In-Sn-Zn oxides through heterostructuring with Bi2Se3 topological insulators. DOI: 10.1038/s41598-023-50809-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How is heat transferred to the sample in a multi gradient experimental tube furnace? Master Precise Heat Control

- What is a drop tube furnace? Ideal for studying rapid combustion and ignition processes.

- What are the common applications of a vacuum tube furnace? Unlock High-Purity Thermal Processing for Your Lab

- In which industries is the tube furnace commonly used? Essential for Materials Science, Energy, and More

- What role does a tubular furnace play in the preparation of biochar? Master Precise Biochar Pyrolysis

- How vacuum pumping affects Zr2.5Nb nitriding? Achieve pure ZrN surfaces in high-temp tube furnaces.

- What critical process conditions does a tube furnace provide for orange peel activated carbon synthesis?

- What are the advantages of horizontal tube furnaces? Achieve Superior Thermal Uniformity and Flexibility