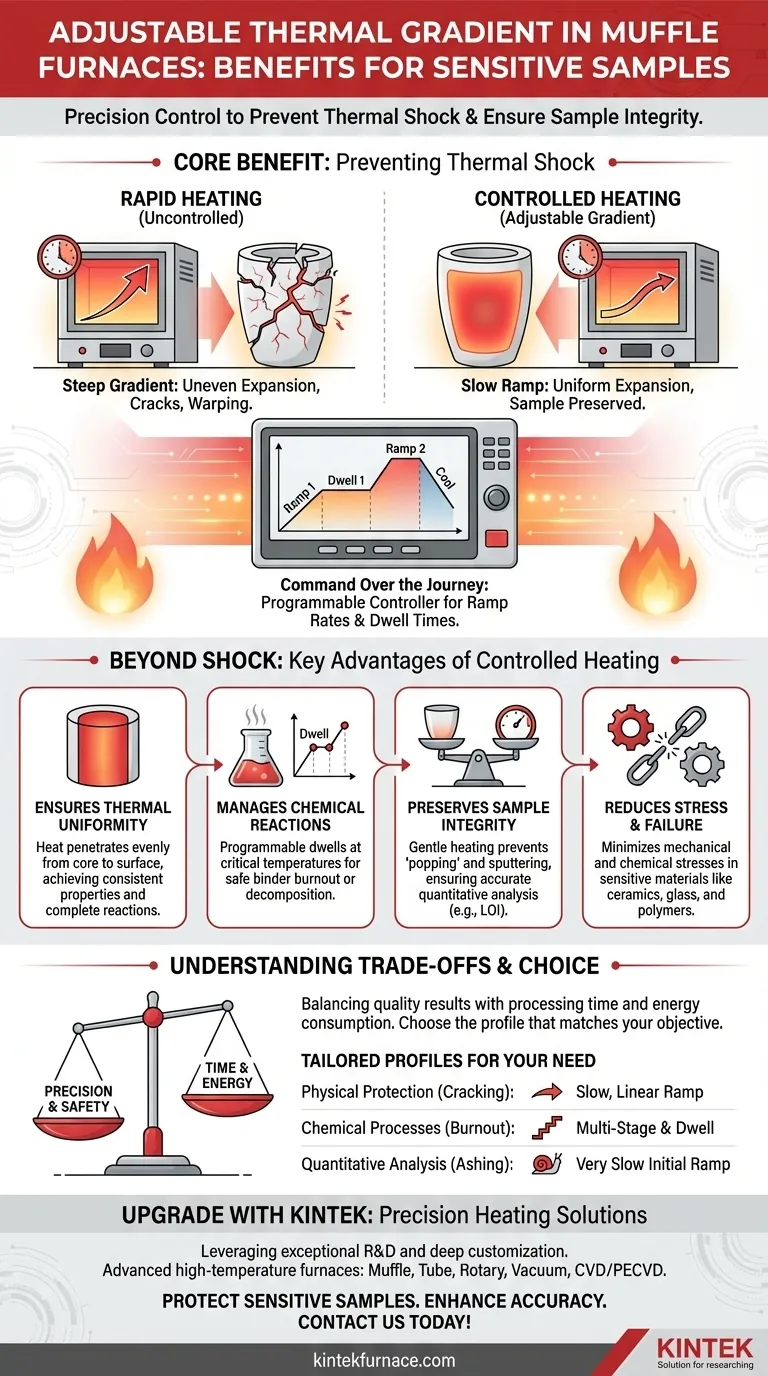

The primary benefit of an adjustable thermal gradient in a muffle furnace is its ability to prevent thermal shock in sensitive samples. By giving you direct control over the rate of temperature increase, often called the "ramp rate," it ensures that a material is heated gently and uniformly. This controlled process avoids the internal stresses that can cause cracking, warping, or unwanted chemical reactions.

The core challenge in high-temperature processing is not just reaching a final temperature, but managing the journey there. An adjustable thermal gradient transforms the furnace from a simple oven into a precision instrument, giving you command over the physical and chemical stresses your sample experiences during heating.

The Physics of Thermal Shock

What is a Thermal Gradient?

In this context, a thermal gradient refers to the rate of temperature change over time. A furnace with a steep, uncontrolled gradient heats up very quickly.

An adjustable thermal gradient means the furnace has a programmable controller that lets you define how fast the temperature rises, if it should hold steady at certain points, and how fast it cools.

How Rapid Heating Creates Stress

Imagine pouring boiling water into a thick, cold glass. The inner surface expands instantly while the outer surface remains cold and contracted. This difference in expansion creates immense internal stress, often causing the glass to crack.

The same principle applies to samples in a furnace. Rapid heating causes the exterior of a sample to expand much faster than its core, introducing mechanical stress that can lead to catastrophic failure.

The Impact on Sensitive Materials

For materials like ceramics or glass, this stress manifests as fractures or cracking, ruining the part.

For polymers, rapid heating can cause uneven melting, warping, or degradation.

For analytical procedures like ashing biological samples, a violent temperature ramp can cause volatile components to erupt, ejecting part of the sample from its crucible and compromising the final measurement.

Beyond Shock: The Benefits of Controlled Heating

Ensuring Thermal Uniformity

A slower ramp rate allows heat to penetrate the sample and establish equilibrium. This ensures the entire volume of the material—from the core to the surface—is at a uniform temperature.

This uniformity is critical for achieving consistent material properties, complete chemical reactions, or accurate analytical results.

Managing Chemical Reactions

Many thermal processes involve controlled chemical changes, such as burning off a polymer binder from a ceramic part (binder burnout) or decomposing organic matter (ashing).

These reactions often need to occur at specific temperatures. An adjustable gradient allows you to program the furnace to ramp up slowly and then dwell (hold a constant temperature) at these critical points, ensuring the reaction completes fully and safely without damaging the sample.

Preserving Sample Integrity

For quantitative analysis like loss-on-ignition (LOI), the goal is to carefully burn off specific components to measure their weight.

A controlled, gentle heating process prevents the sample from "popping" or sputtering, which would result in a physical loss of material and an inaccurate final weight. It ensures the final ash is a true representation of the original material's inorganic content.

Understanding the Trade-offs

Precision vs. Time

The most significant trade-off is processing time. A slow, multi-stage heating profile that guarantees sample safety can take many hours, or even days, to complete.

Labs must balance the need for precision and safety against throughput demands. A faster ramp might be acceptable for robust materials but disastrous for sensitive ones.

Energy Consumption

Longer furnace run times directly translate to higher energy consumption. While often a necessary cost for quality results, it is a practical factor to consider in process optimization and lab budgeting.

Programming Complexity

Creating an optimal heating profile requires knowledge of your material's thermal properties. While modern controllers are user-friendly, determining the correct ramp rates and dwell times for a new material may require research or experimentation.

Making the Right Choice for Your Goal

Ultimately, the ideal thermal gradient is dictated by your material and your objective. An adjustable furnace gives you the flexibility to match the process to the need.

- If your primary focus is preventing physical damage (e.g., cracking ceramics): Use a slow, linear ramp rate to minimize thermal stress throughout the material.

- If your primary focus is managing chemical processes (e.g., binder burnout): Program a multi-stage profile with slow ramps and dedicated "dwell" periods at critical decomposition temperatures.

- If your primary focus is quantitative analysis (e.g., ashing): Employ a very slow initial ramp to gently drive off volatiles before proceeding to the final ashing temperature.

An adjustable thermal gradient empowers you to tailor the heating process to the unique needs of your material, ensuring both the safety of your sample and the integrity of your results.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Thermal Shock | Controlled ramp rates avoid internal stress, reducing cracking and warping. |

| Ensures Uniform Heating | Slow heating allows heat to penetrate evenly for consistent results. |

| Manages Chemical Reactions | Programmable dwell times ensure complete and safe reactions. |

| Preserves Sample Integrity | Gentle heating prevents sample loss in analytical procedures like ashing. |

Upgrade your lab with precision heating solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, protecting sensitive samples and enhancing accuracy. Contact us today to discuss how our tailored furnace solutions can benefit your research and processes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why are precision stirring and drying equipment necessary for photocatalytic materials? Master Microstructure Control

- How does a stainless steel reactor function within a muffle furnace for PET to graphene? Master Carbon Synthesis

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis

- What role does a muffle furnace play in g-C3N4 synthesis? Mastering Thermal Polycondensation for Semiconductors

- What role does a muffle furnace play in the conversion of S-1@TiO2? Achieve Precision Calcination of Nanospheres