In a vacuum environment, melting efficiency improves primarily because the near-absence of air drastically reduces heat loss. Without air molecules to carry heat away through convection and conduction, more of the applied energy is directed into the material itself, resulting in faster, more uniform, and more energy-efficient melting.

While reducing heat loss is the direct answer, the true value of vacuum melting lies in creating a chemically inert environment. This prevents oxidation and contamination, allowing for the production of ultra-pure metals and highly reactive alloys that would be impossible to create otherwise.

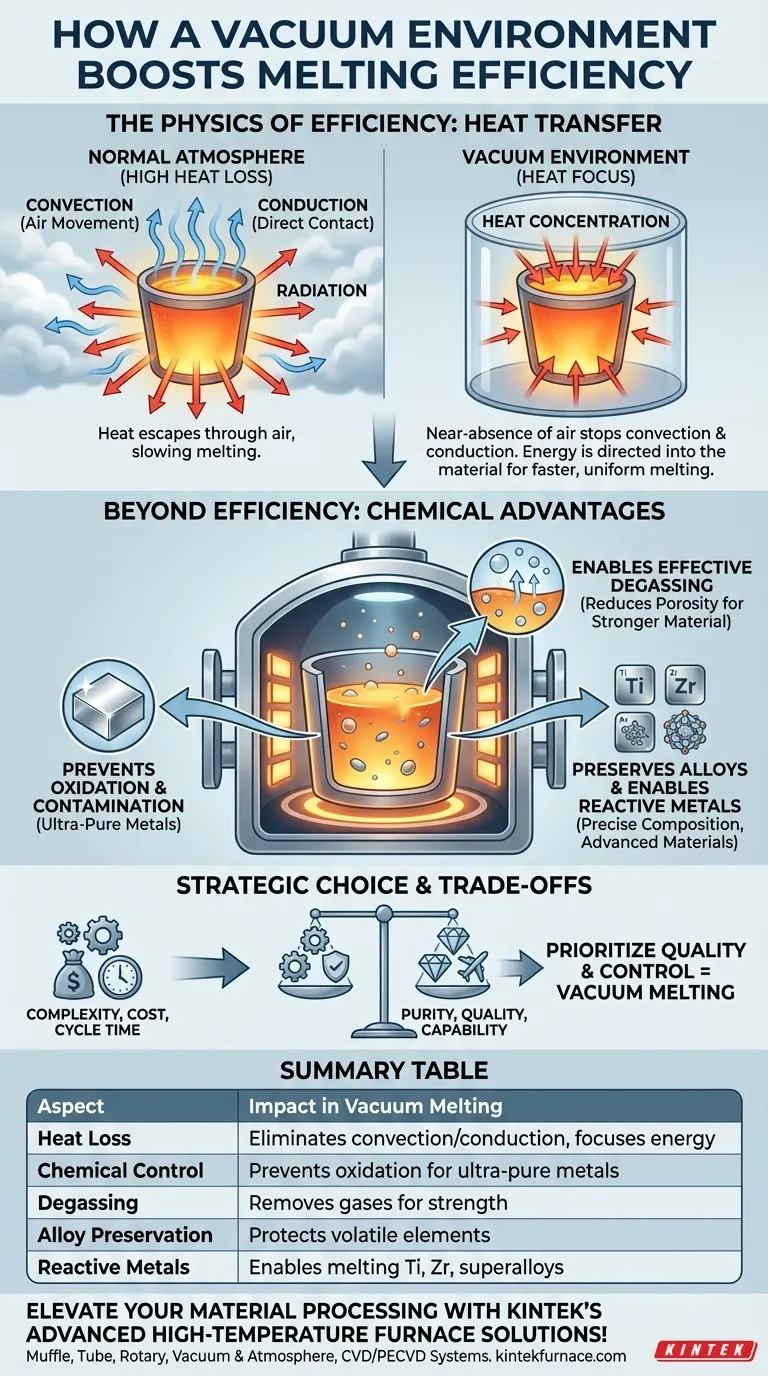

The Physics of Heat Transfer in a Vacuum

The efficiency gain from a vacuum comes from fundamentally changing how heat moves. In a normal atmosphere, heat escapes from a hot object through three methods: conduction, convection, and radiation. A vacuum effectively neutralizes the first two.

Eliminating Convection

Convection is heat transfer through the movement of fluids, like air. Hot air rises from the molten metal's surface, carrying thermal energy away and being replaced by cooler air.

By removing the air, a vacuum eliminates this powerful method of heat loss. There are no air currents to carry heat away from the crucible and the melt.

Minimizing Conduction

Conduction is heat transfer through direct contact. In an atmospheric furnace, air molecules constantly collide with the hot crucible and metal, drawing heat away.

A vacuum drastically reduces the number of molecules available to make contact, nearly stopping conductive heat loss to the surrounding atmosphere. This leaves thermal radiation as the main source of heat loss, which is much less significant in this context.

Beyond Energy: The Chemical Advantages of Vacuum Melting

The deeper, and often more critical, reason for using a vacuum is to gain absolute control over the chemical environment. This moves beyond simple efficiency and into the realm of material quality and capability.

Preventing Oxidation and Contamination

At high temperatures, most metals are highly reactive with oxygen in the air. This reaction, oxidation, forms impurities (oxides) that can compromise the metal's structural integrity.

A vacuum removes the oxygen, preventing these undesirable chemical reactions and ensuring the final product is clean and free of oxide inclusions.

Enabling Effective Degassing

Molten metals can dissolve gases from the atmosphere, particularly hydrogen and nitrogen. When the metal cools and solidifies, these gases can get trapped, creating microscopic pores.

This porosity makes the final material brittle and prone to failure. A vacuum environment not only prevents gases from entering the melt but also helps pull out any dissolved gases already present, resulting in a denser and stronger material.

Preserving Precious Alloying Elements

Creating specific alloys requires a precise recipe of elements. Some of these elements are highly reactive or have a high vapor pressure, meaning they can easily boil off or react with the atmosphere at melting temperatures.

A vacuum furnace protects these volatile and reactive elements, ensuring the final alloy has the exact chemical composition required for its specific properties.

Processing Reactive Metals

Some of the most advanced materials, such as titanium, zirconium, and various superalloys, are extremely reactive. Melting them in air would lead to immediate, catastrophic contamination, rendering them useless.

Vacuum melting is often the only viable method for processing these sensitive materials, enabling industries like aerospace and medical implants.

Understanding the Trade-offs

While powerful, vacuum melting is not a universal solution. It involves specific challenges and costs that must be considered.

Equipment Complexity and Cost

Vacuum furnaces are inherently more complex than their atmospheric counterparts. They require a robust, airtight chamber, powerful vacuum pumping systems, and precise instrumentation.

This leads to significantly higher initial investment and infrastructure costs.

Process Cycle Time

While the melting phase itself may be faster due to better heat retention, the overall process cycle can be longer. Time must be allocated to pump the chamber down to the required vacuum level before heating can even begin.

Maintenance Demands

Maintaining a high-quality vacuum is demanding. The system relies on seals, gaskets, and pumps that require regular inspection and maintenance to prevent leaks, which would compromise the entire process.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace is a strategic one, directly tied to the desired outcome of your material.

- If your primary focus is maximum purity and quality: Vacuum melting is non-negotiable, as it is the only way to prevent oxidation and remove dissolved gases effectively.

- If you are working with reactive metals (e.g., titanium, superalloys): A vacuum environment is an absolute requirement to prevent contamination and ensure material integrity.

- If your goal is simply melting common, non-reactive metals at the lowest cost: A standard atmospheric furnace is often the more practical and economical choice.

Ultimately, choosing a vacuum environment is a decision to prioritize material quality and chemical control over initial cost and operational simplicity.

Summary Table:

| Aspect | Impact in Vacuum Melting |

|---|---|

| Heat Loss | Eliminates convection and conduction, focusing energy on the material |

| Chemical Control | Prevents oxidation and contamination for ultra-pure metals |

| Degassing | Removes dissolved gases to reduce porosity and increase strength |

| Alloy Preservation | Protects volatile elements for precise alloy compositions |

| Reactive Metals | Enables melting of titanium, zirconium, and superalloys |

Elevate your material processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing purity, efficiency, and performance. Contact us today to discuss how we can support your goals with tailored furnace technology!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today