At its core, the difference comes down to mechanics and application. A rotary kiln electric furnace uses a rotating cylindrical chamber to continuously process and uniformly heat granular or powdery materials. A standard retort furnace, by contrast, prioritizes creating a sealed, controlled atmosphere for heat-treating materials, often in a static, batch-based process.

The fundamental choice is between the rotary kiln's continuous, uniform heating through motion and the retort furnace's precise atmospheric control within a sealed chamber. Your material's form and processing goal will dictate which is appropriate.

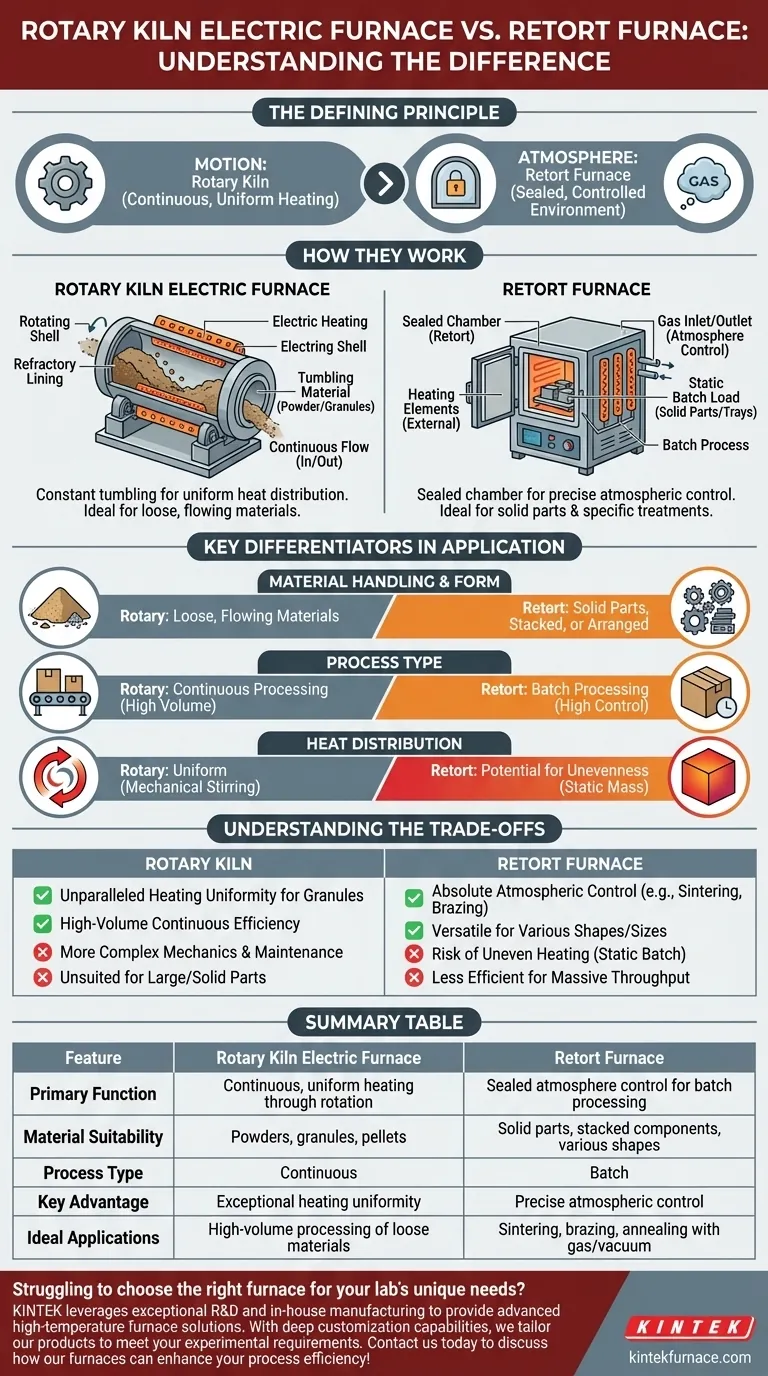

The Defining Principle: Motion vs. Atmosphere

The names of these furnaces reveal their primary functions. One is defined by its movement (rotary kiln), and the other by its containment (retort).

How a Rotary Kiln Electric Furnace Works

A rotary kiln is built around a large, rotating cylindrical shell, or barrel. This shell is lined with refractory material to withstand extreme temperatures.

The shell is mounted on support rollers and angled slightly downwards. Material is fed into the higher end, and the rotation causes it to tumble and move slowly toward the lower end.

This constant tumbling is the kiln's key advantage. It continuously exposes new surfaces of the material—be it powder, granules, or pellets—to the heat source, ensuring exceptionally uniform heat distribution. Electric heating elements provide the precise temperature control needed for the process.

How a Retort Furnace Works

A retort furnace is defined by its sealed chamber, known as a retort. This component is a vessel, often made of metal alloy or ceramic, that holds the material being processed.

The primary purpose of the retort is to isolate the material from the furnace's heating elements and the outside air. This allows for precise atmospheric control.

The chamber can be filled with inert gases to prevent oxidation, reactive gases for specific chemical processes, or placed under a vacuum. This makes it ideal for treatments like sintering, brazing, and annealing where the atmospheric conditions are critical to the outcome. While some retorts can rotate, the term "retort furnace" most often implies a static, sealed chamber for batch processing.

Key Differentiators in Application

Understanding how each furnace operates reveals which is best suited for a specific industrial task.

Material Handling and Form

A rotary kiln is specifically designed for loose, flowing materials. The tumbling action that ensures uniform heating would damage or be ineffective for large, solid, or precisely arranged parts.

A static retort furnace excels where the material's shape or position must be maintained. It can handle stacked components, large single parts, or materials in trays without disturbing them.

Process Type: Continuous vs. Batch

The design of a rotary kiln makes it inherently suited for continuous processing. Material can be fed in and discharged constantly, making it highly efficient for high-volume production.

Retort furnaces are typically used for batch processing. A specific quantity of material is loaded, the retort is sealed, the heat treatment cycle is run, and the entire batch is removed. This provides high control but is less efficient for massive throughput compared to a continuous system.

Heat Distribution

While both can use efficient electric heating, the method of heat transfer differs. In a static furnace, heat must penetrate a stationary mass, which can create temperature differences between the surface and the core.

The rotary kiln solves this by constantly mixing the material. This mechanical "stirring" action provides a more consistent radial temperature throughout the entire volume of material.

Understanding the Trade-offs

Neither furnace is universally superior; they are specialized tools with distinct advantages and limitations.

The Rotary Kiln: Uniformity at a Cost

The primary advantage is unparalleled heating uniformity for granular materials. This leads to highly consistent and predictable product quality.

However, its mechanical systems—the drive gear, shell, and support structure—are more complex and require more maintenance than a simple static furnace. It is also completely unsuited for processing large, non-tumbling items.

The Retort Furnace: Control and Versatility

The key strength of a retort furnace is its absolute atmospheric control, which is non-negotiable for many advanced material treatments. It is also versatile, capable of handling materials of nearly any shape or size.

The main drawback, especially in static configurations, is the risk of uneven heating. Materials at the edge of a batch may heat faster than those in the center, potentially leading to inconsistent results if not managed carefully. While offering quicker heating times, maintaining uniformity across a large, static batch can be a challenge.

Making the Right Choice for Your Goal

Your decision should be guided by your material and your process requirements.

- If your primary focus is continuous, high-volume processing of powders or granules: The rotary kiln electric furnace is designed for this exact purpose, offering unmatched heating uniformity.

- If your primary focus is precise atmospheric control for batch treatments: The retort furnace is the definitive choice, especially for solid parts or processes like sintering and annealing.

- If your primary focus is achieving the most consistent temperature possible throughout a loose material: The mechanical tumbling action of a rotary kiln is superior to any static heating method.

Ultimately, selecting the correct furnace is about aligning the equipment's core strengths with the critical demands of your application.

Summary Table:

| Feature | Rotary Kiln Electric Furnace | Retort Furnace |

|---|---|---|

| Primary Function | Continuous, uniform heating through rotation | Sealed atmosphere control for batch processing |

| Material Suitability | Powders, granules, pellets | Solid parts, stacked components, various shapes |

| Process Type | Continuous | Batch |

| Key Advantage | Exceptional heating uniformity | Precise atmospheric control |

| Ideal Applications | High-volume processing of loose materials | Sintering, brazing, annealing with gas/vacuum |

Struggling to choose the right furnace for your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we tailor our products to precisely meet your experimental requirements, ensuring optimal performance for materials like powders or batch-processed parts. Contact us today to discuss how our furnaces can enhance your process efficiency and results!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput