At its core, a rotary furnace is a simple and powerful machine. It is a large, rotating cylinder, mounted at a slight angle, that continuously tumbles material through a high-temperature environment. This combination of rotation and tilt ensures that every particle of the material is consistently mixed and uniformly exposed to heat, resulting in a highly consistent final product.

The genius of the rotary furnace is not just in its ability to heat materials, but in its use of gravity and mechanical motion. By constantly tumbling the charge material as it flows through the heated chamber, it solves the fundamental problem of uneven heating common in static furnaces.

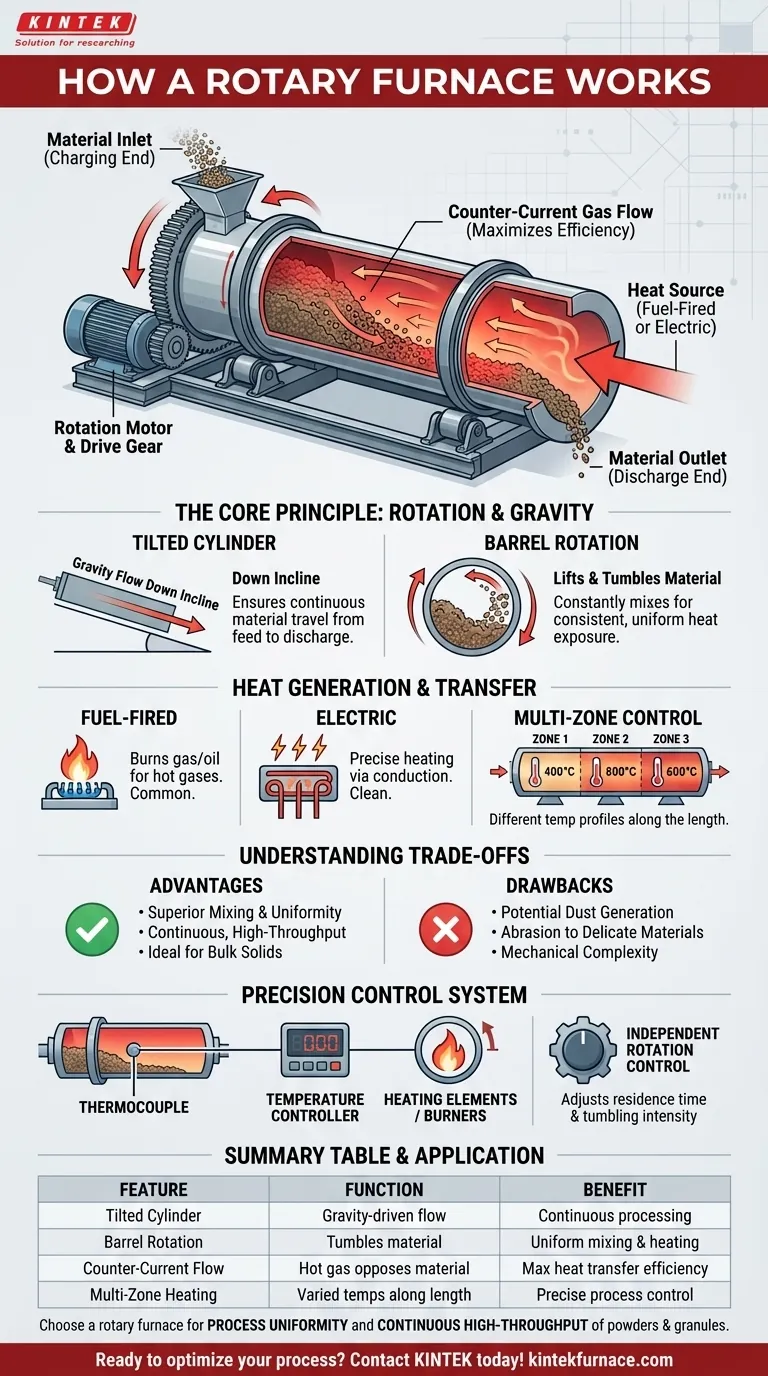

The Core Principle: Combining Rotation and Gravity

The effectiveness of a rotary furnace comes from the interplay of its two most basic design features: its tilt and its rotation.

The Tilted Cylinder Design

The entire furnace barrel is mounted on a slight incline. This angle allows gravity to do its work, ensuring that material fed into the higher end (the charging end) will slowly and predictably travel down the length of the cylinder to the lower end (the discharge end).

The Role of Rotation

An independent motor turns the cylindrical barrel around its longitudinal axis. As the barrel rotates, it lifts the material up its inner wall until gravity overcomes friction, causing the material to tumble back down to the bottom. This continuous lifting and tumbling action is the key to its function.

The Result: Uniform Processing

This constant tumbling ensures the material is thoroughly mixed. It prevents any part of the charge from sitting at the bottom and overheating or staying at the top and remaining too cool. Every particle is repeatedly exposed to the heat source, guaranteeing exceptionally uniform heating, drying, or chemical reaction.

How Heat is Generated and Transferred

A rotary furnace is a highly controlled thermal environment. The method of heating is critical to its function and can be adapted to the specific process requirements.

Fuel-Fired vs. Electric Heating

There are two primary methods for heating the furnace.

- Fuel-Fired (Indirect): In this common design, fuels like gas, oil, or pulverized solids are burned to create hot gases. These gases are then passed through the furnace chamber to heat the material.

- Electric (Direct/Indirect): Heating elements can be placed outside the rotating barrel, transferring heat through the barrel wall via conduction. This method offers very precise temperature control.

The Counter-Current Flow Advantage

In most fuel-fired designs, the hot gases are directed to flow in the opposite direction of the material. This counter-current flow is highly efficient. The hottest gases encounter the most processed material near the discharge end, while the cooler, exiting gases encounter the cold, incoming material, maximizing heat transfer efficiency.

Multi-Zone Temperature Control

Modern rotary furnaces often feature multi-zone heating. This allows different temperature profiles to be set for different sections along the length of the barrel. This precision is essential for complex processes that require specific heating, soaking, and cooling phases.

Understanding the Trade-offs

While powerful, the rotary furnace is not a universal solution. Understanding its inherent trade-offs is key to its proper application.

Key Advantages

The continuous tumbling action provides unparalleled mixing, leading to superior temperature uniformity and product consistency. The design is also naturally suited for continuous, high-throughput industrial processes rather than batch work.

Potential Drawbacks

The same tumbling action that ensures uniformity can be a disadvantage for certain materials. It can create dust with fine powders or cause abrasion and damage to delicate or friable materials. The mechanical systems, including the rotational drive and seals, can also add complexity compared to a simple static furnace.

The Control System: Ensuring Precision

Precise control over temperature and rotation is what makes the rotary furnace a reliable industrial tool.

The Thermocouple's Role

A thermocouple is a sensor inside the furnace that measures the internal temperature. It converts this heat reading into a small electrical signal.

The Controller's Logic

This signal is sent to a temperature controller. The controller continuously compares the actual temperature from the thermocouple to the desired setpoint temperature. If there's a difference, it automatically adjusts the power to the heating elements or the fuel flow to the burners to maintain a stable, accurate temperature.

Independent Rotation Control

The speed of the furnace's rotation is also a critical, controllable variable. Adjusting the rotation speed changes how long the material stays in the furnace (its "residence time") and the intensity of the tumbling action, providing another layer of process control.

Making the Right Choice for Your Process

Applying a rotary furnace successfully depends on matching its strengths to your material and goals.

- If your primary focus is process uniformity: A rotary furnace is an excellent choice for ensuring every particle of a bulk solid receives the same thermal treatment.

- If your primary focus is continuous, high-throughput production: The furnace's design is inherently built for moving material from input to output, making it ideal for industrial-scale operations.

- If you are processing powders, granules, or non-friable solids: The tumbling action is highly effective for these material types, but you must account for potential dust generation or abrasion.

Ultimately, the rotary furnace is a specialized tool designed to solve the challenge of uniform thermal processing for bulk materials in a continuous flow.

Summary Table:

| Feature | Function | Benefit |

|---|---|---|

| Tilted Cylinder | Creates a gravity-driven flow of material | Enables continuous processing from feed to discharge |

| Barrel Rotation | Lifts and tumbles material continuously | Ensures uniform mixing and consistent heat exposure |

| Counter-Current Flow | Hot gases flow opposite to material direction | Maximizes heat transfer efficiency |

| Multi-Zone Heating | Allows different temperatures along the furnace length | Provides precise control for complex thermal processes |

Ready to achieve superior uniformity and efficiency in your thermal processing?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to deliver advanced rotary furnace solutions tailored to your unique needs. Whether you're processing powders, granules, or other bulk solids, our expertise ensures your high-throughput production goals are met with precision.

Our product line, including Rotary Furnaces, Muffle Furnaces, Tube Furnaces, and CVD/PECVD Systems, is backed by strong deep customization capabilities to perfectly match your experimental and industrial requirements.

Contact us today to discuss how a KINTEK rotary furnace can optimize your process!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs