At its core, a multi-speed furnace works by using a sophisticated blower motor that can operate at several distinct speeds, not just "on" or "off." Unlike a standard furnace that runs at 100% capacity every time it kicks on, a multi-speed model can select a lower, more energy-efficient speed to gently circulate air and maintain temperature. This ability to adjust its fan speed is the key to its improved comfort and efficiency.

The fundamental advantage of a multi-speed furnace is its ability to match its output to the real-time heating needs of your home. By running at a lower speed for longer periods, it avoids the inefficient, full-blast cycles of older systems, resulting in more consistent heat and lower energy consumption.

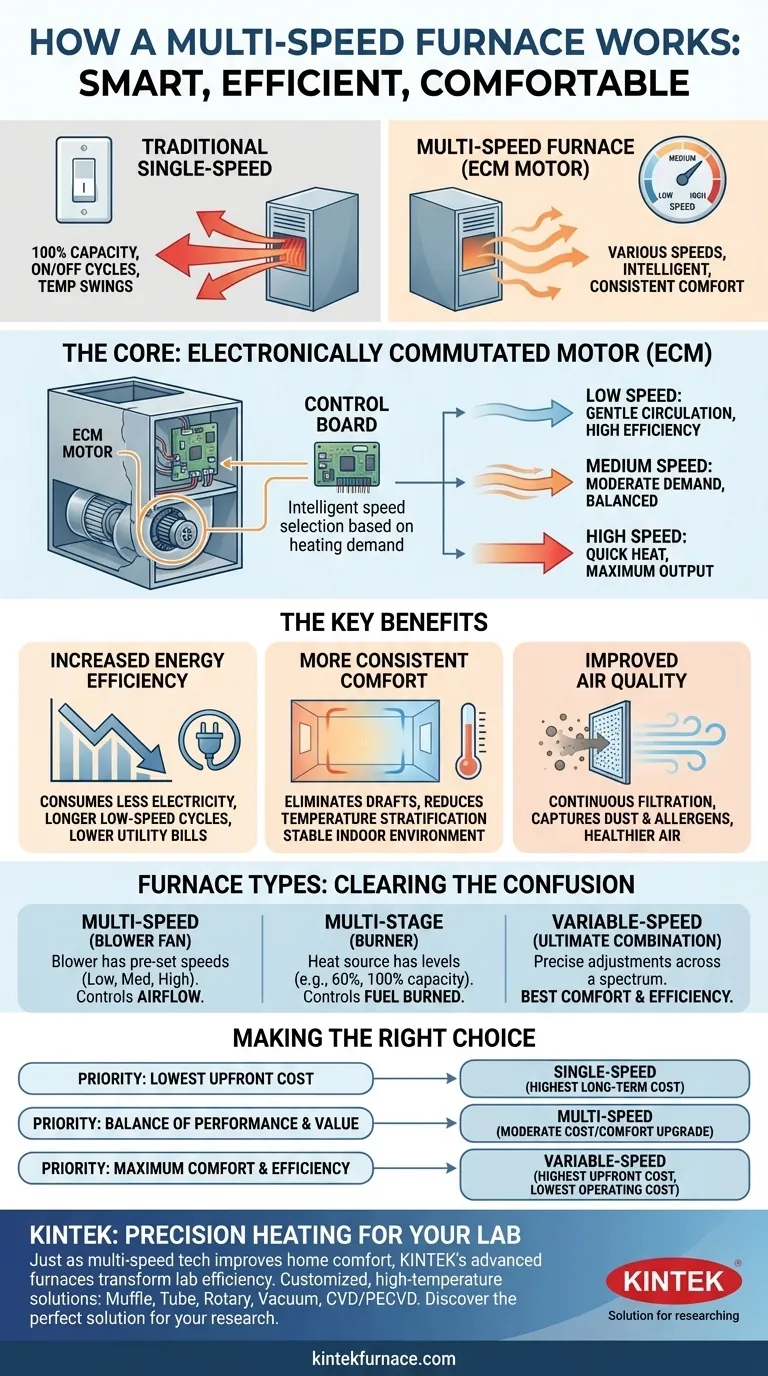

The Core Difference: Single-Speed vs. Multi-Speed Operation

To understand a multi-speed furnace, it's best to compare it to the traditional single-speed model it was designed to improve upon.

The Standard Single-Speed Furnace

A traditional furnace operates like a simple light switch: it's either fully on or completely off.

When the thermostat calls for heat, the blower motor kicks on at its maximum and only speed, delivering a powerful blast of hot air until the target temperature is reached, then shuts down completely. This creates noticeable temperature swings and is less energy-efficient.

The Multi-Speed Furnace Motor

A multi-speed furnace uses an Electronically Commutated Motor (ECM) for its blower fan. This advanced motor is programmed to operate at several fixed speeds—for example, a low, medium, and high setting.

The furnace's control board intelligently chooses the appropriate speed based on the heating demand. A small temperature drop might only require the low speed, while a significant drop would trigger the high speed.

The Benefits of Running at Slower Speeds

The ability to run at lower fan speeds is more than a minor feature; it fundamentally changes the way your home is heated and provides several distinct advantages.

Increased Energy Efficiency

An ECM blower motor running at a lower speed consumes significantly less electricity than a standard motor running at full blast.

Even though the furnace runs for longer cycles, the total energy consumption is lower, leading to savings on your utility bills. Some systems can reduce blower capacity to as low as 40% of their maximum output.

More Consistent Comfort

The "on/off" cycle of a single-speed furnace leads to temperature stratification—hot air rises, cool air settles, and you feel drafts.

A multi-speed furnace's long, low-speed cycles provide a constant, gentle circulation of warm air. This process mixes the air more thoroughly, eliminating hot and cold spots and creating a far more stable and comfortable indoor environment.

Improved Air Quality

Because the blower fan runs more consistently, air is passed through your furnace filter more frequently.

This continuous filtration is more effective at capturing dust, allergens, and other airborne particulates, leading to cleaner, healthier indoor air.

Clearing Up Common Confusion: Types of Furnaces

The terms "multi-speed," "multi-stage," and "variable-speed" are often used interchangeably, but they refer to different components and levels of performance.

Multi-Speed (The Blower Fan)

This term refers specifically to the blower motor having a few pre-set speeds (e.g., low, medium, high). It controls how fast air is moved.

Multi-Stage (The Burner)

This term refers to the heat source itself. A two-stage furnace, for example, has two levels of heat output: a low-fire setting (perhaps 60-70% capacity) and a high-fire setting (100%). It controls how much fuel is burned.

Variable-Speed (The Ultimate Combination)

A true variable-speed furnace is the most advanced. It typically combines a multi-stage burner with a blower motor that can make tiny, precise adjustments across a wide spectrum of speeds, not just a few fixed ones. This offers the absolute best in comfort and efficiency.

Understanding the Trade-offs

While multi-speed technology offers clear benefits, it's important to consider the drawbacks to make a fully informed decision.

Higher Upfront Cost

Furnaces equipped with ECM motors are more technologically advanced than their single-speed counterparts. This results in a higher initial purchase and installation cost.

Repair and Replacement Costs

The ECM motor is a more complex and expensive component. Should it fail outside of its warranty period, the cost to repair or replace it is significantly higher than for a simple, standard furnace motor.

Making the Right Choice for Your Goal

Selecting a furnace is a long-term investment in your home's comfort and operational costs. The right choice depends entirely on your priorities.

- If your primary focus is the lowest upfront cost: A traditional single-speed furnace is the most budget-friendly option at the time of purchase, but it will have the highest long-term energy costs and lowest level of comfort.

- If your primary focus is a balance of performance and value: A multi-speed furnace offers a significant upgrade in comfort and efficiency over a basic model without the premium price tag of a top-tier variable-speed system.

- If your primary focus is maximum comfort and long-term efficiency: A true variable-speed furnace, ideally paired with a multi-stage burner, delivers the most stable temperatures and lowest operating costs over its lifespan.

By understanding how these different technologies work, you can confidently choose the system that best aligns with your budget and your expectations for home comfort.

Summary Table:

| Feature | Single-Speed Furnace | Multi-Speed Furnace |

|---|---|---|

| Operation | On/Off (100% capacity) | Multiple fixed speeds (e.g., low, medium, high) |

| Motor Type | Standard motor | Electronically Commutated Motor (ECM) |

| Comfort | Temperature swings, drafts | Consistent heat, no cold spots |

| Efficiency | Lower (runs at full blast) | Higher (can run as low as 40% capacity) |

| Air Quality | Basic filtration | Continuous, improved filtration |

| Cost | Lower upfront cost | Higher initial investment, lower long-term energy bills |

Upgrade Your Lab's Heating with Precision-Engineered Furnaces from KINTEK

Just as a multi-speed furnace revolutionizes home comfort, KINTEK's advanced high-temperature furnace solutions transform laboratory efficiency and accuracy. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with cutting-edge heating systems tailored to your unique experimental needs.

Our product line includes:

- Muffle Furnaces: Ideal for precise ash content determination and heat treatment.

- Tube Furnaces: Perfect for controlled atmosphere applications and materials research.

- Rotary Furnaces: Excellent for continuous processing and uniform heating.

- Vacuum & Atmosphere Furnaces: Designed for sensitive processes requiring specific environments.

- CVD/PECVD Systems: Advanced solutions for thin-film deposition and coating applications.

With strong deep customization capabilities, KINTEK ensures your furnace precisely matches your research requirements, delivering unparalleled temperature control, energy efficiency, and reliability.

Ready to enhance your lab's performance? Contact our experts today to discuss your specific needs and discover the perfect furnace solution for your laboratory.

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does a multi-zone tube furnace achieve precise temperature gradient control? Master MoS2 Isotope Monolayer Synthesis

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What safety precautions should be followed when operating a multi zone tube furnace? Ensure Safe and Efficient Lab Operations