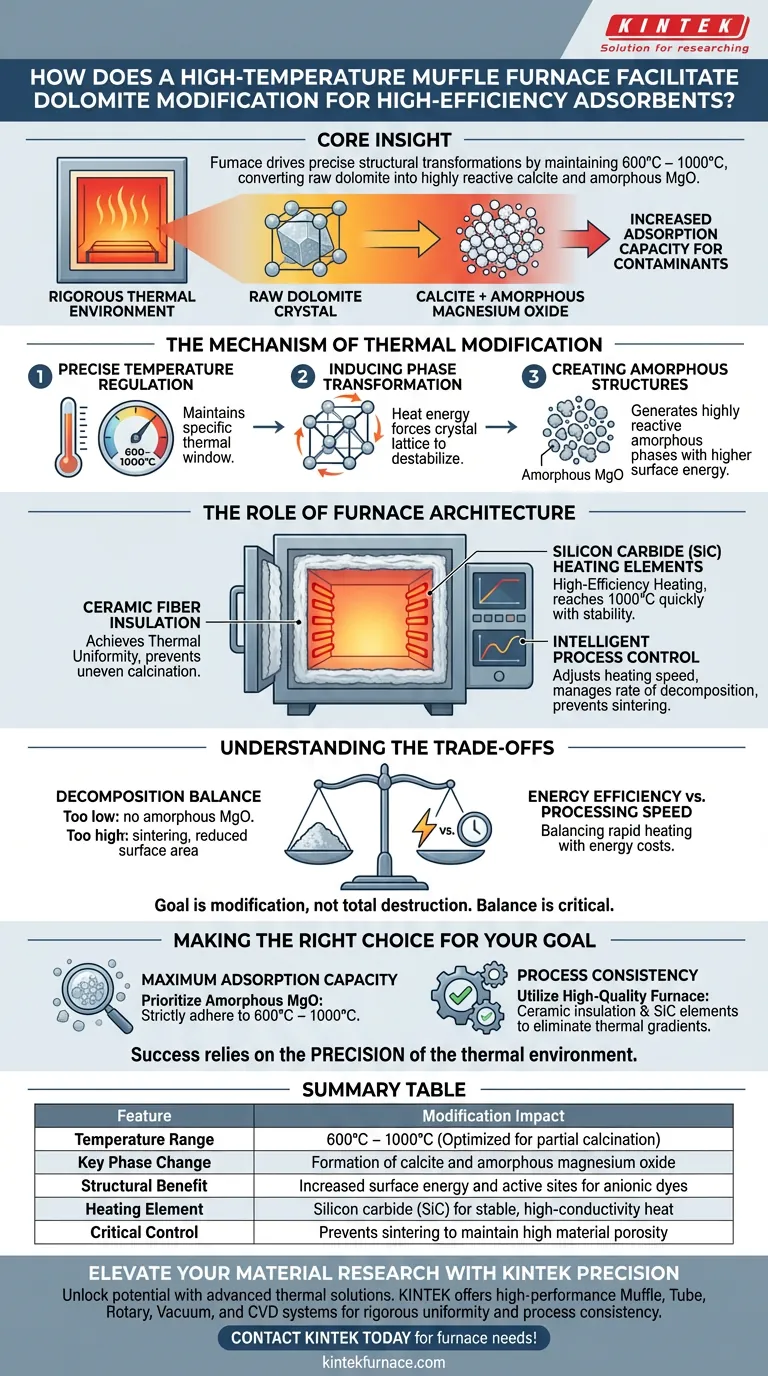

A high-temperature muffle furnace facilitates dolomite modification by creating a rigorously controlled thermal environment essential for partial calcination. By subjecting the material to constant heating between 600°C and 1000°C, the furnace drives precise structural transformations that convert raw dolomite into a highly reactive adsorbent.

Core Insight: The muffle furnace is not merely a heating source; it is an instrument of structural engineering. It facilitates the partial decomposition of dolomite into calcite and amorphous magnesium oxide, a phase change that directly correlates to a significant increase in adsorption capacity for contaminants like anionic dyes.

The Mechanism of Thermal Modification

Precise Temperature Regulation

The modification of dolomite is highly sensitive to temperature. The muffle furnace allows you to maintain a specific thermal window, typically 600°C to 1000°C.

Inducing Phase Transformation

Within this temperature range, the heat energy forces the dolomite crystal lattice to destabilize. This is not a total disintegration, but a controlled partial conversion.

Creating Amorphous Structures

The process generates amorphous magnesium oxide alongside calcite. Unlike crystalline structures, amorphous phases often possess higher surface energy and reactivity, which is critical for binding contaminants.

The Role of Furnace Architecture

Achieving Thermal Uniformity

Muffle furnaces utilize advanced ceramic fiber insulation to minimize heat loss. This ensures that the thermal environment surrounding the dolomite sample is uniform, preventing uneven calcination.

High-Efficiency Heating Elements

To reach and sustain temperatures up to 1000°C, these furnaces often employ silicon carbide (SiC) heating elements. These components provide high thermal conductivity and stability, allowing the system to reach the target temperature quickly.

Intelligent Process Control

Modern muffle furnaces feature intelligent heating functions that adjust the heating speed. This control is vital for managing the rate of decomposition, ensuring the dolomite structure changes predictably without sintering into a non-porous mass.

Understanding the Trade-offs

The Balance of Decomposition

Temperature control is critical because the goal is modification, not total destruction. If the temperature is too low, the amorphous magnesium oxide will not form; if it is too high or held too long, the material may sinter, reducing its surface area and adsorption capability.

Energy Efficiency vs. Processing Speed

High-temperature processing is energy-intensive. While high-efficiency insulation and "energy-saving modes" help, operating at 1000°C requires significant power. You must balance the need for rapid heating with the energy costs of sustained high-temperature operations.

Making the Right Choice for Your Goal

To maximize the efficacy of your dolomite-based adsorbents, consider the following:

- If your primary focus is maximum adsorption capacity: Prioritize the generation of amorphous magnesium oxide by strictly adhering to the 600°C–1000°C window to ensure active sites are created for anionic dyes.

- If your primary focus is process consistency: Utilize a furnace with high-quality ceramic insulation and SiC elements to eliminate thermal gradients that could lead to heterogeneous product quality.

Success in dolomite modification relies less on maximum heat and more on the precision of the thermal environment.

Summary Table:

| Feature | Modification Impact |

|---|---|

| Temperature Range | 600°C – 1000°C (Optimized for partial calcination) |

| Key Phase Change | Formation of calcite and amorphous magnesium oxide |

| Structural Benefit | Increased surface energy and active sites for anionic dyes |

| Heating Element | Silicon carbide (SiC) for stable, high-conductivity heat |

| Critical Control | Prevents sintering to maintain high material porosity |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your adsorption materials with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to provide the rigorous temperature uniformity required for complex dolomite modification.

Whether you need standard lab equipment or a fully customizable high-temp furnace tailored to your unique research parameters, our systems ensure process consistency and structural integrity for every sample.

Ready to optimize your adsorbent synthesis? Contact KINTEK today to speak with our technical experts about your high-temperature furnace needs!

Visual Guide

References

- Zhaohui Li, Shangping Xu. Anionic Dye Alizarin Red S Removal Using Heat-Treated Dolomite. DOI: 10.3390/cryst14020187

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the main advantage of a muffle furnace? Ensure Purity and Longevity in High-Temp Processes

- Why is heat treatment in a muffle furnace required for bioactive glass pellets? Ensure Sterile Biological Testing

- What are the main functions of muffle furnaces in materials processing? Achieve Precise, Clean Thermal Control for Your Lab

- Why is a muffle furnace utilized for primary heat treatment at 250 °C? Optimize Your Perovskite Catalyst Structure

- Why is operator training important for muffle furnace use? Ensure Safety, Accuracy, and Longevity

- What are the primary applications of muffle furnaces in materials research? Unlock Precision in Synthesis and Analysis

- What are the key benefits of using a muffle furnace? Achieve Precise, Contaminant-Free High-Temperature Control

- What key technologies were employed in the muffle furnace for environmental sample analysis? Achieve Accurate and Reliable Results