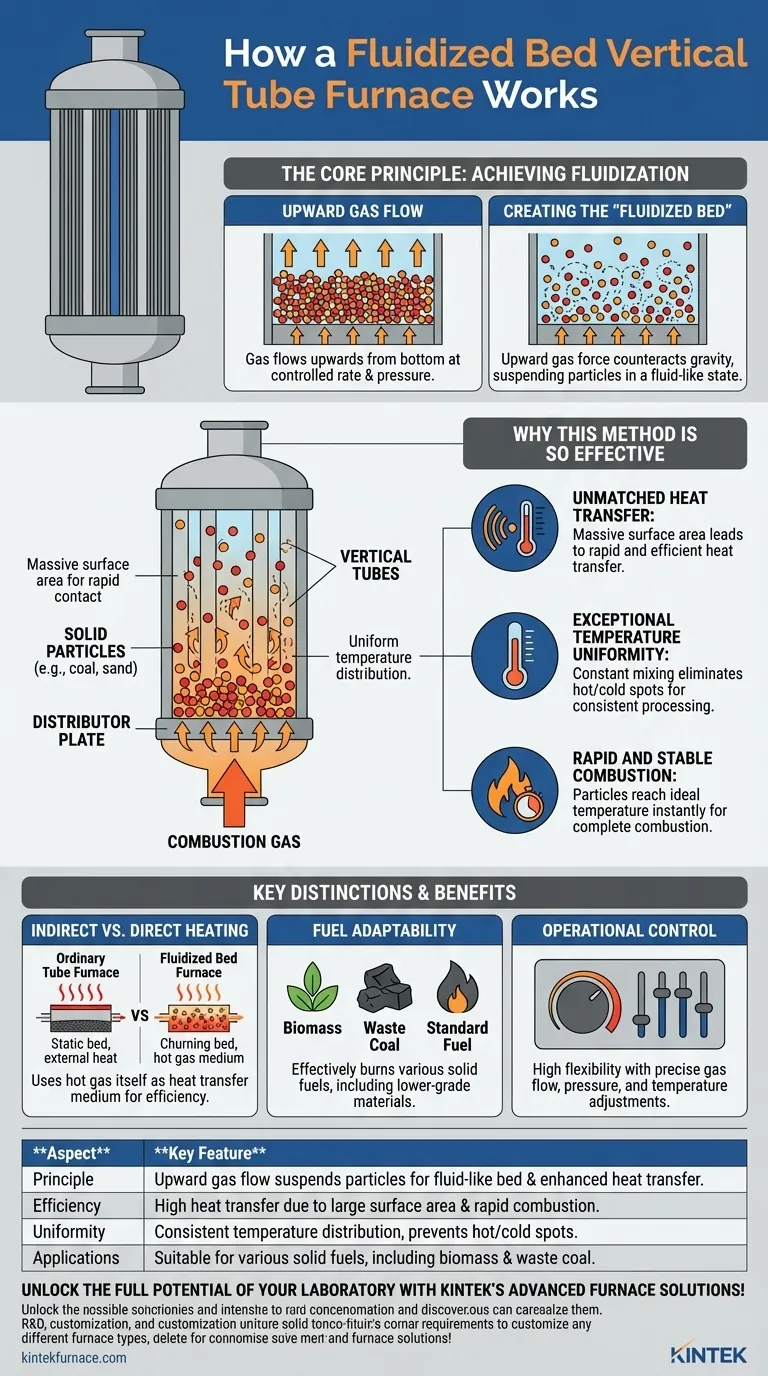

At its core, a fluidized bed vertical tube furnace works by using an upward flow of gas to suspend solid fuel particles, causing them to behave like a churning, hot fluid. This "fluidized bed" creates an exceptionally large surface area for contact between the gas and the solid particles. The result is incredibly uniform heating and highly efficient combustion.

The key innovation is not merely suspending particles, but creating a dynamic system that solves the persistent problems of uneven heating and poor heat transfer common in conventional furnaces. It transforms a static pile of solid fuel into a highly reactive, fluid-like mass.

The Core Principle: Achieving Fluidization

A fluidized bed furnace operates on a simple but powerful principle of physics. The vertical design is not an arbitrary choice; it is fundamental to how the system functions.

The Role of Upward Gas Flow

The process begins by forcing a combustion gas upwards from the bottom of the furnace's vertical tubes. The flow rate and pressure of this gas are precisely controlled.

This upward stream of gas flows through a distributor plate and into the bed of solid particulate material (such as coal, sand, or biomass).

Creating the "Fluidized Bed"

As the gas velocity increases, it exerts a drag force on the solid particles. At a specific velocity, this upward force counteracts the downward force of gravity, and the particles become suspended in the gas stream.

The entire mass of churning, suspended particles begins to exhibit the properties of a liquid—it can be stirred and will flow. This state is known as the fluidized bed. The constant friction and vortex effects keep the particles in motion.

The Vertical Tube Design

The vertical orientation of the furnace and its internal tube bundles is critical. This structure uses gravity to its advantage, ensuring that gas can flow smoothly upwards to create and maintain the fluidized state without obstruction.

Why This Method is So Effective

The value of fluidization lies in its ability to dramatically improve the fundamental processes of combustion and heat transfer. It overcomes limitations inherent in static fuel beds.

Unmatched Heat Transfer Efficiency

In a traditional furnace, heat must slowly conduct through a static pile of fuel. In a fluidized bed, the massive surface area of the suspended particles is constantly exposed to the hot gas, resulting in extremely rapid and efficient heat transfer.

Exceptional Temperature Uniformity

The constant, vigorous mixing of particles within the bed eliminates hot spots and cold spots. The temperature throughout the entire volume of the bed is remarkably consistent, ensuring uniform processing and preventing material degradation.

Rapid and Stable Combustion

Because particles are heated so quickly and efficiently, they reach their ideal combustion temperature almost instantly. This leads to a faster, more complete, and more stable combustion process compared to static bed systems.

Understanding the Key Distinctions

A fluidized bed furnace is fundamentally different from a standard tube furnace. Understanding these differences reveals its unique advantages and applications.

Indirect vs. Direct Heating

Ordinary tube furnaces often rely on electric heating elements to heat the air or the tube walls, which then radiates heat to the material inside. A fluidized bed furnace uses the hot gas itself as the heat transfer medium, directly fluidizing and heating the solid particles for a much more efficient process.

Operational Control and Flexibility

Control is achieved by dynamically adjusting the gas flow rate, pressure, and temperature. This gives operators a high degree of flexibility to fine-tune the combustion process in real-time.

Fuel Adaptability

The stable combustion environment and high heat transfer rates allow these furnaces to effectively burn a wide variety of solid fuels, including lower-grade materials like biomass and waste coal, that are challenging for other systems.

Making the Right Choice for Your Application

Choosing the right heating technology depends entirely on your primary objective.

- If your primary focus is maximum thermal efficiency: The immense gas-solid contact area in a fluidized bed offers superior performance and fuel savings.

- If your primary focus is processing temperature-sensitive materials: The exceptional temperature uniformity of the fluidized bed minimizes the risk of product damage from hot spots.

- If your primary focus is fuel diversity and flexibility: This furnace's ability to handle various solid fuels and its precise operational control make it a highly adaptable choice.

Ultimately, mastering the flow of gas and solids allows you to achieve a level of heating control and efficiency that is difficult to replicate with other methods.

Summary Table:

| Aspect | Key Feature |

|---|---|

| Principle | Upward gas flow suspends solid particles, creating a fluid-like bed for enhanced heat transfer. |

| Efficiency | High heat transfer due to large surface area and rapid combustion. |

| Uniformity | Consistent temperature distribution prevents hot spots and cold spots. |

| Applications | Suitable for various solid fuels, including biomass and waste coal. |

Unlock the full potential of your laboratory with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Fluidized Bed, Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, delivering superior efficiency, uniformity, and fuel adaptability. Don't settle for less—contact us today to discuss how we can enhance your processes and drive innovation in your lab!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability