At its core, a dental furnace improves the quality of dental restorations by providing an environment of exceptionally precise control. It uses meticulously managed temperature cycles and vacuum atmospheres to transform raw ceramic or zirconia materials into a final product with superior strength, aesthetics, and fit, eliminating the imperfections that occur in less controlled conditions.

The function of a dental furnace goes far beyond simple heating. It is a precision instrument that governs the microscopic process of sintering, ensuring that powdered materials coalesce into a dense, non-porous solid that is both strong enough for clinical function and aesthetically indistinguishable from a natural tooth.

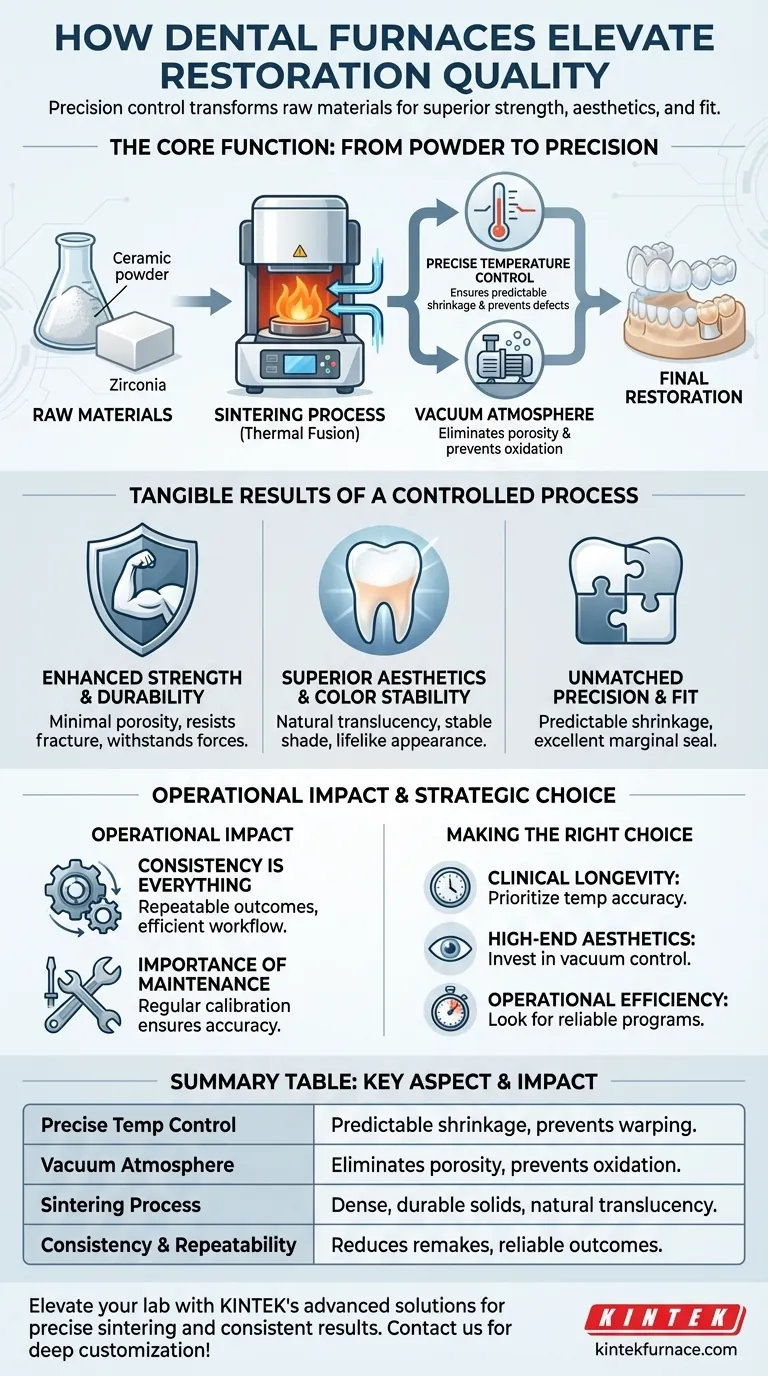

The Core Function: From Powder to Precision Prosthetic

A furnace's primary job is to manage the sintering process. This is where the quality of the final restoration is truly decided.

What is Sintering?

Sintering is a thermal process that fuses particles of a material, like zirconia or ceramic powder, into a solid, coherent mass. This is achieved through heat and pressure, applied just below the material's melting point.

Proper sintering is what gives a restoration its final density, strength, and predictable dimensions.

The Critical Role of Temperature Control

The furnace’s most important function is its ability to maintain exact temperatures throughout a firing cycle. Even minor deviations can compromise the restoration.

Accurate temperature control ensures the material shrinks predictably, achieving the correct final size for a perfect fit. It also prevents internal stresses that can lead to warping or cracking, which are catastrophic failures.

The Power of a Vacuum Atmosphere

Many high-end furnaces operate under a vacuum. By removing air from the firing chamber, the furnace creates an ideal environment for ceramic materials.

This vacuum prevents oxidation, which can discolor the restoration and create a gray, lifeless appearance. It also draws out any trapped air from within the ceramic, eliminating porosity. A non-porous restoration is significantly stronger and more translucent.

The Tangible Results of a Controlled Process

The precise control offered by a quality furnace translates directly into measurable clinical and aesthetic benefits.

Enhanced Strength and Durability

A restoration with minimal porosity is inherently stronger. By eliminating microscopic voids that act as stress points, the furnace produces crowns and bridges that can better withstand the immense forces of chewing.

This leads to durable, long-lasting restorations with a much lower risk of fracture over time.

Superior Aesthetics and Color Stability

The vacuum environment is key to achieving natural-looking aesthetics. By preventing oxidation, the furnace ensures the ceramic's programmed shade remains true and stable.

This allows for the creation of restorations with the complex translucency, value, and hue of a natural tooth, enabling seamless integration into the patient's smile.

Unmatched Precision and Fit

Consistent temperature and controlled heating and cooling rates lead to predictable shrinkage. This allows dental technicians to design restorations with confidence, knowing the final product will match the digital design.

The result is an excellent marginal fit, which is critical for preventing leakage, recurrent decay, and gum irritation.

Understanding the Operational Impact

While the clinical quality is paramount, the choice of a furnace also has significant practical implications for a dental lab or practice.

Consistency is Everything

A high-quality furnace delivers repeatable and predictable outcomes. This consistency is the foundation of an efficient workflow, reducing the need for costly remakes and adjustments.

When a technician can trust the furnace to execute a program flawlessly every time, they can focus on the artistry of the restoration itself.

The Importance of Maintenance

The precision of a furnace is not permanent. Regular calibration of its temperature sensors (thermocouple) is essential to ensure it continues to operate accurately.

Neglecting maintenance can lead to a gradual decline in quality, with restorations that are weak, ill-fitting, or aesthetically poor.

In-House vs. Outsourcing

Bringing a furnace in-house gives a dental practice ultimate control over quality and turnaround time. It allows for better customization and eliminates the costs and delays associated with shipping to an external laboratory.

However, this also requires an investment in the equipment and the skilled personnel required to operate it effectively.

Making the Right Choice for Your Goal

The specific features you prioritize in a furnace should align with the primary goals of your practice or laboratory.

- If your primary focus is clinical longevity: Prioritize furnaces with proven temperature accuracy and consistency to maximize restoration strength and minimize porosity.

- If your primary focus is high-end aesthetics: Invest in a furnace with excellent vacuum control and programmable cycles to achieve superior color stability and natural translucency.

- If your primary focus is operational efficiency: Look for furnaces that offer reliable, repeatable programs and faster cooling cycles to increase throughput without sacrificing quality.

Ultimately, mastering the use of a high-quality dental furnace is a direct investment in the quality of care you provide.

Summary Table:

| Key Aspect | Impact on Restoration Quality |

|---|---|

| Precise Temperature Control | Ensures predictable shrinkage for perfect fit and prevents warping/cracking |

| Vacuum Atmosphere | Eliminates porosity for enhanced strength and prevents oxidation for superior aesthetics |

| Sintering Process | Transforms powders into dense, durable solids with natural tooth-like translucency |

| Consistency and Repeatability | Reduces remakes, improves workflow efficiency, and ensures reliable outcomes |

Elevate your dental lab's capabilities with KINTEK's advanced dental furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces tailored for precise sintering, vacuum control, and consistent results. Our products, including Muffle, Tube, and Vacuum Furnaces, are designed to meet your unique needs for strength, aesthetics, and efficiency. Contact us today to discuss how our deep customization can enhance your restoration quality and boost your practice's success!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations