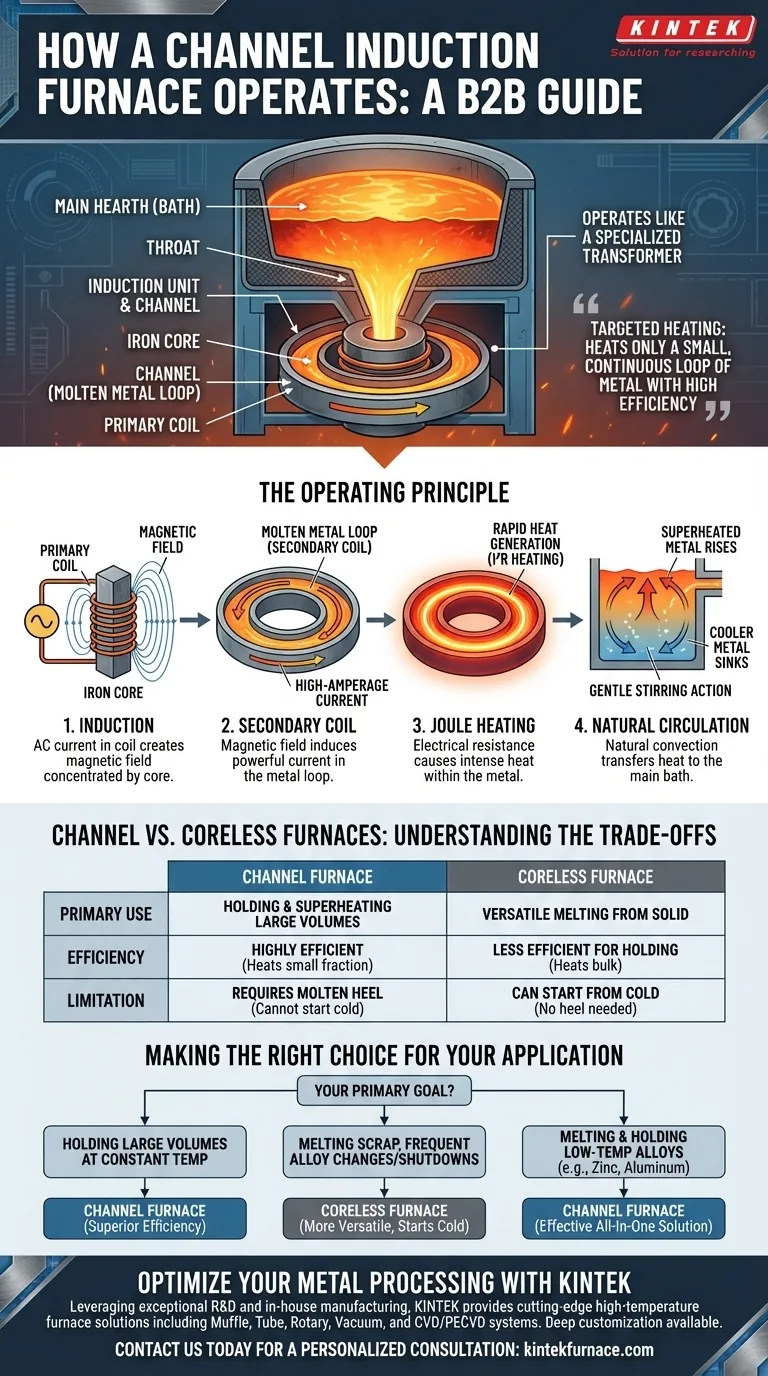

At its core, a channel induction furnace operates like a specialized transformer. The furnace uses a primary electrical coil and an iron core to induce a powerful secondary current within a contained loop, or "channel," of molten metal. This induced current generates intense heat directly within the metal, which then circulates into the main furnace chamber to heat the larger bath.

The defining characteristic of a channel furnace is its method of targeted heating. Unlike other furnaces that heat the entire metal charge at once, a channel furnace heats only a small, continuous loop of metal with high efficiency, making it exceptionally well-suited for holding and maintaining the temperature of large volumes of liquid metal.

The Anatomy of a Channel Furnace

To understand the operation, you must first visualize its key components. The design is a clever integration of a container and a heating engine.

The Main Hearth

The main hearth, or bath, is the large, refractory-lined steel vessel that contains the bulk of the molten metal. Its primary role is simply to hold the liquid charge safely.

The Induction Unit and Channel

Connected to the bottom or side of the main hearth is the induction unit. This unit contains a closed loop or channel, also lined with refractory material. A "throat" connects this channel to the main hearth, allowing molten metal to flow between the two.

The Transformer Assembly

The induction unit is built around a transformer design. A primary induction coil, powered by an AC source, is wound around a laminated iron core. This core is shaped to pass through the opening of the molten metal channel without touching it. The metal inside the channel effectively becomes the secondary "coil" of the transformer.

The Operating Principle: A Transformer in Action

The heating process is a direct application of electromagnetic principles, occurring in a continuous cycle.

Step 1: Induction

When alternating current flows through the primary coil, it generates a powerful and rapidly changing magnetic field. The iron core concentrates this magnetic field and directs it efficiently through the loop of molten metal in the channel.

Step 2: The Molten Metal Secondary Coil

This concentrated magnetic field induces a very high-amperage, low-voltage current in the single turn of the molten metal loop. The liquid metal completes a secondary electrical circuit.

Step 3: Joule Heating

The molten metal has inherent electrical resistance. As the massive induced current flows through it, this resistance causes rapid and intense heat generation (Joule's Law, or I²R heating). This heat is generated only within the metal inside the channel.

Step 4: Natural Circulation and Stirring

The superheated, less-dense metal in the channel rises into the main hearth through the throat. Cooler, denser metal from the hearth sinks to take its place in the channel, creating a continuous, natural convection loop. This process efficiently transfers heat to the entire bath and provides a gentle, useful stirring action.

Understanding the Trade-offs: Channel vs. Coreless Furnaces

The design of the channel furnace gives it specific advantages and disadvantages, especially when compared to its counterpart, the coreless induction furnace.

Why Use a Channel Furnace? Efficiency in Holding

Because a channel furnace only heats a small fraction of the total metal volume at any given time, it is extremely energy-efficient for maintaining temperature or slightly increasing it (superheating). This makes it the preferred technology for holding large quantities of molten metal, such as in die casting operations or as a buffer for a primary melting furnace.

The Critical Limitation: The Need for a Molten Heel

A channel furnace cannot start from a cold, solid state. It requires a continuous loop of molten metal to complete the secondary circuit. This initial charge, known as a "heel," must be supplied from another source. Attempting to start with solid metal would be like having an open secondary circuit on a transformer.

When a Coreless Furnace Is Better: Versatility in Melting

A coreless induction furnace works differently. Its primary coil surrounds the entire crucible, inducing eddy currents throughout the bulk of the metal charge. This allows it to melt metal from a solid state, making it far more versatile for melting scrap, changing alloys frequently, and starting and stopping operations.

Making the Right Choice for Your Application

Selecting the correct induction furnace technology depends entirely on your operational goals.

- If your primary focus is holding large volumes of molten metal at a constant temperature: The channel furnace is superior due to its high electrical efficiency for this specific task.

- If your primary focus is melting solid scrap or requiring frequent shutdowns and alloy changes: The coreless furnace is the more versatile and logical choice as it does not require a molten heel to operate.

- If your primary focus is melting and holding low-temperature alloys like zinc or aluminum: A channel furnace can be an effective all-in-one solution, as the energy required for melting is lower.

Understanding this fundamental difference between the targeted heating of a channel furnace and the bulk heating of a coreless furnace empowers you to select the most cost-effective and operationally sound solution for your foundry.

Summary Table:

| Aspect | Description |

|---|---|

| Operation Principle | Functions as a transformer with a primary coil inducing current in a molten metal channel loop, generating heat via Joule's Law. |

| Key Components | Main hearth (holds metal), induction unit with channel, transformer assembly (coil and iron core). |

| Heating Process | Induced current in channel metal causes I²R heating, with natural circulation transferring heat to the main bath. |

| Primary Use | Efficient for holding and superheating large volumes of molten metal; requires a molten heel to start. |

| Comparison | More energy-efficient for holding than coreless furnaces, but less versatile for melting from solid state. |

Optimize Your Metal Processing with KINTEK's Advanced Furnace Solutions

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories and industrial facilities with cutting-edge high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Whether you need efficient holding solutions like channel furnaces or versatile melting options, we can tailor our equipment to enhance your operational efficiency and cost-effectiveness. Contact us today to discuss how our expertise can benefit your specific application—reach out via our contact form for a personalized consultation!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide