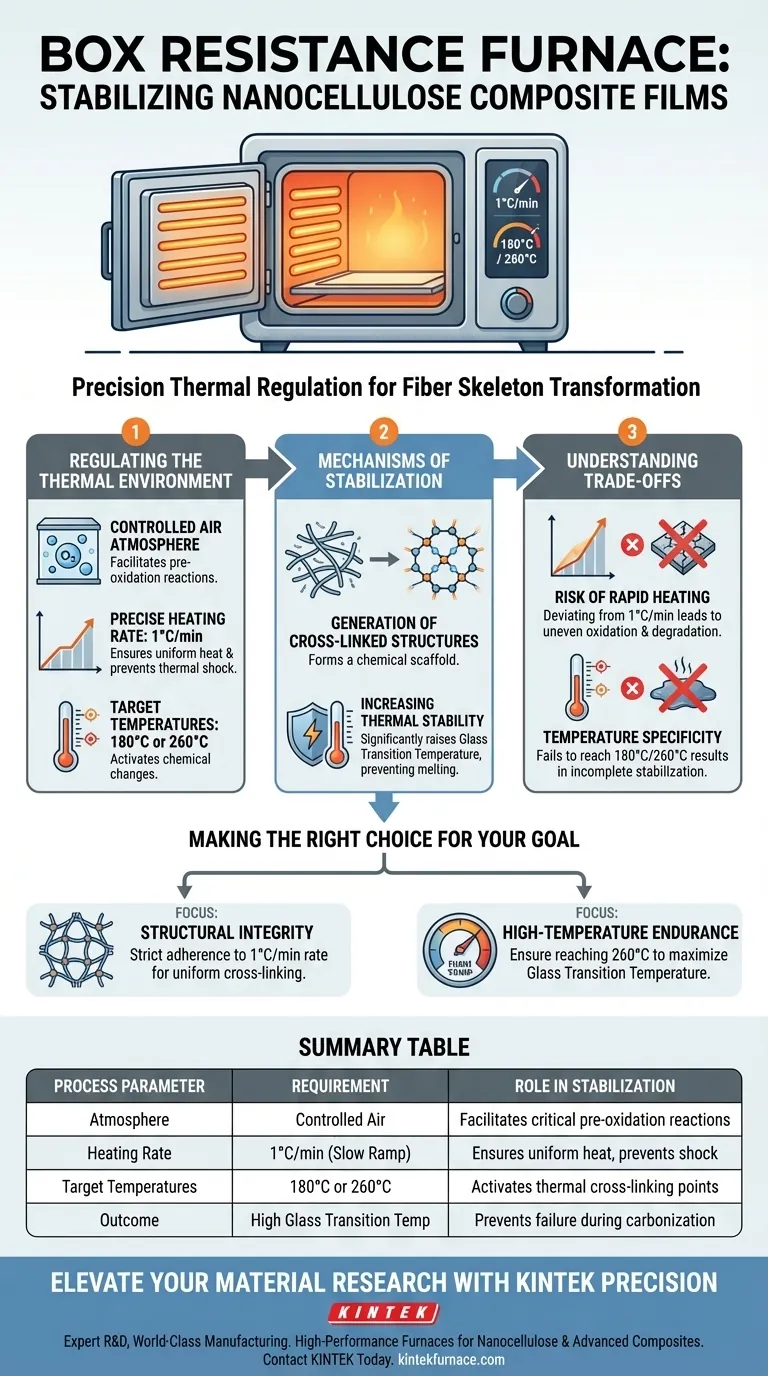

A Box Resistance Furnace functions as a precision thermal regulation tool during the stabilization phase of nanocellulose composite films. It creates a controlled air environment that subjects the material to a slow, specific heating ramp—typically 1°C/min—up to target temperatures such as 180°C or 260°C to induce essential pre-oxidation reactions.

The core purpose of this phase is to transform the fiber skeleton through thermal cross-linking, significantly raising the material's glass transition temperature to prevent melting or structural failure during later high-temperature processing.

Regulating the Thermal Environment

Controlled Air Atmosphere

The furnace maintains an air environment rather than an inert vacuum or gas atmosphere.

This presence of oxygen is necessary to facilitate pre-oxidation reactions on the surface and within the structure of the composite films.

Precise Heating Rates

The furnace must deliver a highly controlled heating rate, specifically 1°C/min.

This slow ramp is critical to ensure uniform heat distribution and prevents thermal shock, allowing the chemical structure to evolve gradually rather than burning or degrading rapidly.

Target Temperature Maintenance

The equipment is programmed to reach and stabilize at specific plateaus, such as 180°C or 260°C.

These temperatures are the activation points required to initiate the necessary chemical changes without destroying the underlying nanocellulose morphology.

Mechanisms of Stabilization

Generation of Cross-linked Structures

The heat provided by the furnace promotes the formation of cross-linked structures within the fiber skeleton.

This cross-linking acts as a chemical scaffold, reinforcing the material at a molecular level.

Increasing Thermal Stability

As these cross-links form, the material’s thermal stability increases significantly.

This process also raises the glass transition temperature, changing the film from a material that might easily soften to one that is rigid and heat-resistant.

Understanding the Trade-offs

The Risk of Rapid Heating

The primary pitfall in this process is deviating from the 1°C/min heating rate.

Accelerating this rate can lead to uneven oxidation or thermal degradation, preventing the formation of a uniform cross-linked network.

Temperature Specificity

Failing to reach the target temperatures (180°C or 260°C) results in incomplete stabilization.

An under-stabilized film will likely suffer from structural failure or melting when subjected to the much higher temperatures of subsequent carbonization.

Making the Right Choice for Your Goal

To ensure the successful conversion of nanocellulose films, apply these operational principles:

- If your primary focus is Structural Integrity: Adhere strictly to the 1°C/min heating rate to ensure uniform cross-linking throughout the fiber skeleton.

- If your primary focus is High-Temperature Endurance: Ensure the furnace reaches the higher threshold of 260°C to maximize the glass transition temperature before carbonization.

By using the Box Resistance Furnace to lock in the fiber structure now, you safeguard the material against failure in future high-heat applications.

Summary Table:

| Process Parameter | Requirement | Role in Stabilization |

|---|---|---|

| Atmosphere | Controlled Air | Facilitates critical pre-oxidation reactions |

| Heating Rate | 1°C/min (Slow Ramp) | Ensures uniform heat distribution & prevents shock |

| Target Temperatures | 180°C or 260°C | Activates thermal cross-linking points |

| Outcome | High Glass Transition Temp | Prevents structural failure during carbonization |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect 1°C/min stabilization ramp requires absolute thermal control. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the rigorous demands of nanocellulose and advanced composite processing.

Whether you need a standard Box Resistance Furnace or a fully customizable high-temperature system for unique research needs, our lab solutions ensure your materials maintain structural integrity every time.

Ready to optimize your thermal stabilization? Contact KINTEK today to find the perfect furnace for your laboratory.

Visual Guide

References

- Suman, Bharat Bajaj. Low-Temperature Carbonization of Phosphorus-Doped Nanocellulose for Carbon Nanofiber Film Fabrication. DOI: 10.1007/s11837-024-07098-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does a resistance furnace play in ZK61 magnesium alloy treatment? Mastering Homogenization & Microstructure

- What role does a high-temperature box resistance furnace play in converting LDHs into LDOs? Essential Thermal Insights

- What role does a muffle furnace play in eggshell pretreatment? Optimize CaO Production with Precise Calcination

- What is the use of muffle furnace in laboratory? Achieve Pure, High-Temperature Heat for Accurate Analysis

- What materials can crucible furnaces melt? A Guide to Metals, Glass & Advanced Materials

- What are the key features of modern electrical muffle furnaces? Achieve Precise, Pure, and Efficient High-Temp Processing

- What are some advancements in modern muffle furnace technology? Boost Precision and Efficiency in Your Lab

- What safety features should a muffle furnace have? Essential Protections for Your Lab's Safety