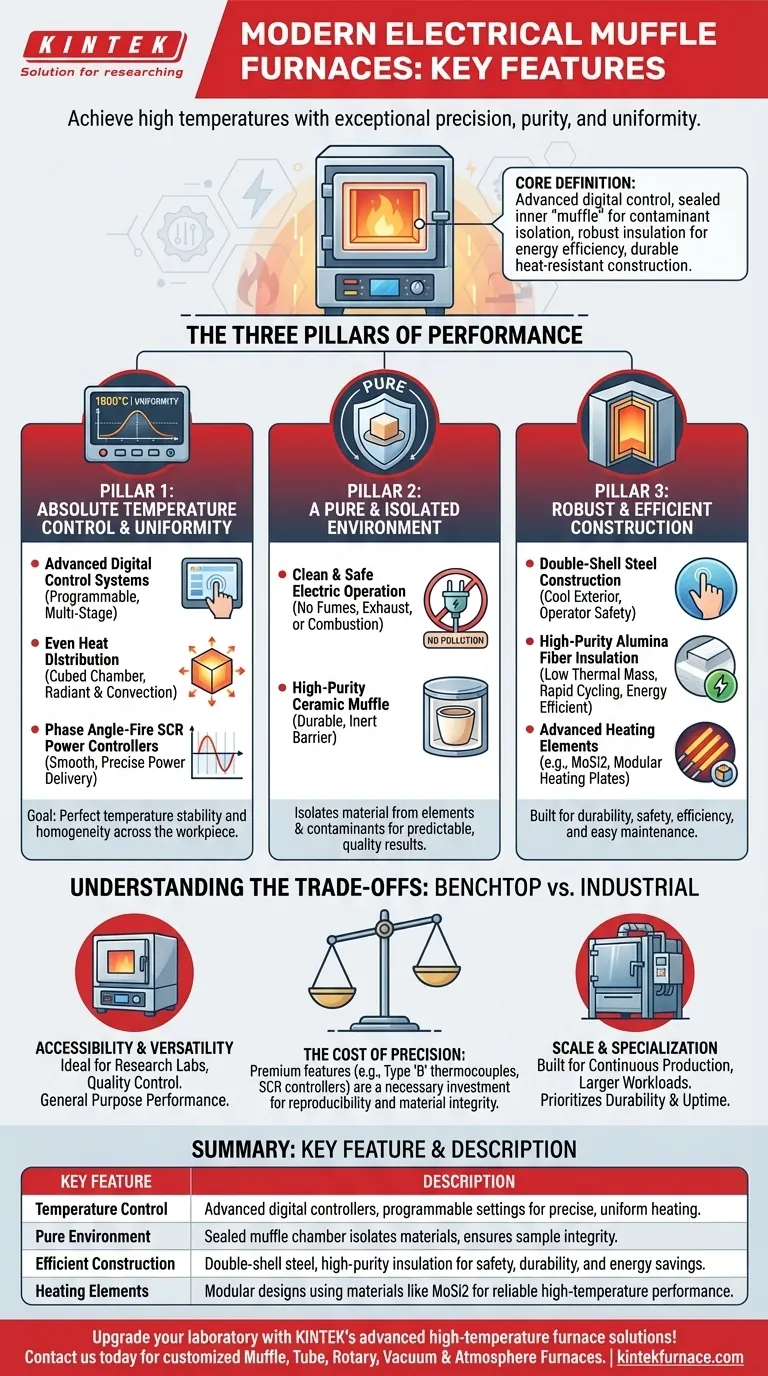

At their core, modern electrical muffle furnaces are defined by their ability to achieve extremely high temperatures with exceptional precision and purity. Their key features include advanced digital temperature control systems for uniformity, a sealed inner chamber (the "muffle") that isolates materials from contaminants, robust insulation for energy efficiency, and durable, heat-resistant construction for safety and longevity.

A muffle furnace is more than just a high-temperature oven. Its defining features work in concert to create a perfectly stable, uniform, and pure heating environment, ensuring that results are predictable, repeatable, and of the highest quality.

The Three Pillars of Furnace Performance

The effectiveness of a modern muffle furnace rests on three fundamental pillars: how it controls heat, how it protects the material being heated, and how it is built to withstand extreme conditions efficiently.

Pillar 1: Absolute Temperature Control and Uniformity

The primary goal is not just to get hot, but to achieve a specific temperature and hold it perfectly steady across the entire workpiece.

Modern furnaces use advanced temperature control systems, often with programmable digital controllers. This allows operators to set precise temperatures, ramp-up rates, and dwell times for complex, multi-stage processes.

To ensure the temperature is the same everywhere, furnaces rely on even heat distribution. This is achieved through a combination of radiant and convection heat, often within a cubed chamber, which is geometrically ideal for creating a homogeneous thermal environment.

Premium models use sophisticated phase angle-fire SCR power controllers to deliver smooth, precise power to the heating elements, eliminating the temperature fluctuations common with simpler on/off controllers.

Pillar 2: A Pure and Isolated Environment

The term "muffle" refers to the inner chamber that separates the material being processed from the heating elements and outside contaminants. This isolation is critical.

By using clean and safe electric operation, these furnaces produce no fumes, exhaust, or combustion byproducts that could react with and contaminate the sample. This is essential for applications like creating high-purity metals or sensitive chemical analysis.

The muffle itself is made from materials like high-purity ceramic, which creates a durable, inert barrier. This ensures that the only thing affecting the workpiece is the heat itself.

Pillar 3: Robust and Efficient Construction

A furnace must be built for durability, safety, and efficiency.

High-end models feature double-shell steel construction. This design allows for airflow between the inner and outer walls, keeping the exterior of the furnace cool to the touch even when the interior is at 1800°C, ensuring operator safety.

Modern insulation, such as high-purity alumina fiber, has low thermal mass. This allows the furnace to heat up and cool down rapidly while using less energy, improving operational efficiency.

The heating elements themselves are a key feature. Premium furnaces use advanced materials like molybdenum disilicide (MoSi2) to reach the highest temperatures reliably. Often, these are designed as modular heating plates, which makes replacement and maintenance far simpler.

Understanding the Trade-offs

Not all muffle furnaces are created equal. The features you need depend entirely on your application, and the primary trade-off is often between the accessibility of a benchtop model and the specialized power of an industrial unit.

Benchtop Models: Accessibility and Versatility

These smaller units are the workhorses of research labs, quality control departments, and small-scale workshops. They offer excellent performance for their size and are designed for general-purpose applications.

While highly capable, a standard benchtop model may not have the most advanced SCR power controllers or the same level of over-temperature monitoring as a premium industrial furnace.

Industrial Models: Scale and Specialization

Built for production environments, these larger furnaces are designed for continuous operation and handling bigger workloads. They typically come standard with the most robust features.

These units prioritize durability and ease of maintenance, often including features like fan-cooled element terminals and modular components to minimize downtime.

The Cost of Precision

Features that deliver the highest levels of performance—such as Type 'B' thermocouples for extreme temperature accuracy, independent over-temperature safety controls, and SCR power controllers—add to the cost. However, for applications where reproducibility and material integrity are non-negotiable, they are a necessary investment.

Making the Right Choice for Your Goal

Selecting a furnace requires matching its features to your specific operational needs.

- If your primary focus is research and material analysis: Prioritize a furnace with the most precise programmable controls, a cubed chamber for uniformity, and a high-purity muffle.

- If your primary focus is quality control or prototyping: A durable benchtop model with good insulation for rapid cycling and reliable safety features offers the best balance of performance and cost.

- If your primary focus is high-volume industrial production: Invest in a furnace with modular heating elements for easy maintenance, robust double-shell construction, and advanced over-temperature protection to ensure uptime and safety.

Ultimately, a modern muffle furnace is defined not just by the heat it generates, but by the perfect control it provides over that heat.

Summary Table:

| Key Feature | Description |

|---|---|

| Temperature Control | Advanced digital controllers with programmable settings for precise, uniform heating. |

| Pure Environment | Sealed muffle chamber isolates materials from contaminants, ensuring sample integrity. |

| Efficient Construction | Double-shell steel and high-purity insulation for safety, durability, and energy savings. |

| Heating Elements | Modular designs using materials like MoSi2 for reliable high-temperature performance. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our strong deep customization capability ensures precise performance for research, quality control, or industrial production. Contact us today to discuss how our furnaces can enhance your efficiency and results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity