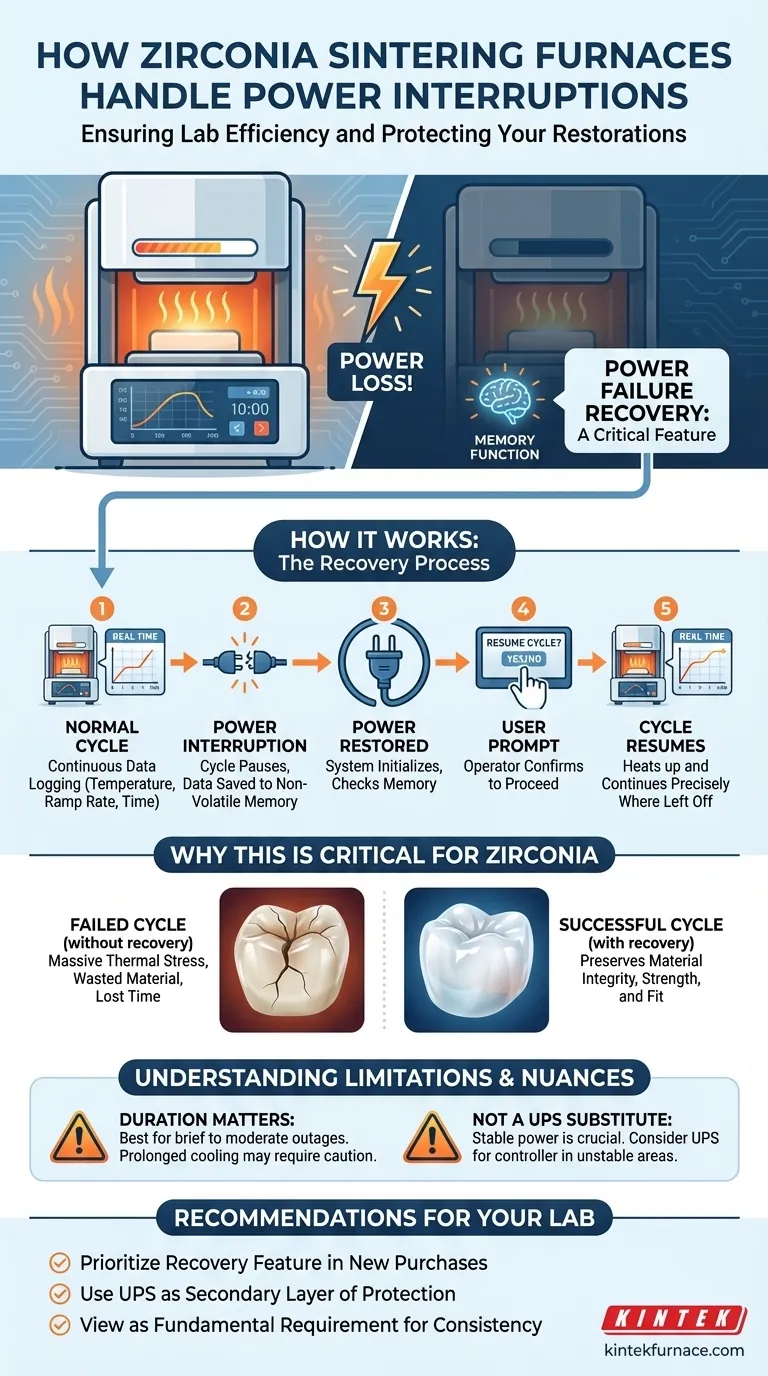

Modern zirconia sintering furnaces are engineered to handle power interruptions through a critical feature known as a power failure recovery or memory function. This system continuously records the progress of the sintering cycle—including the current temperature, ramp rate, and time elapsed. If power is lost, the furnace retains this data and, upon power restoration, can resume the cycle precisely from the point of interruption, preventing a costly failed cycle.

The primary risk of a power interruption during sintering is a ruined restoration, leading to wasted materials and significant lost time. Modern furnaces are designed to mitigate this risk with a memory function that allows the cycle to resume seamlessly, ensuring the integrity of the final zirconia prosthesis and protecting your lab's investment.

How Power Failure Recovery Works

The ability to recover from a power outage is not a minor convenience; it is a core function of the furnace's sophisticated process controller. This technology is fundamental to ensuring predictable and successful outcomes.

The Role of the Internal Memory

At the heart of this feature is an onboard controller with non-volatile memory. This controller acts as the furnace's brain, constantly saving the state of the active sintering program.

Every critical parameter is logged in real-time. This means the furnace knows exactly where it was in the temperature curve when the power was cut.

The Resumption Process

When power is restored, the furnace's control system immediately initializes. It checks its memory and detects that an active cycle was interrupted.

Typically, the user is presented with a prompt on the touch screen, asking whether to resume the cycle. This gives the operator final control, allowing them to proceed with the recovery or cancel the cycle if necessary. Once confirmed, the furnace reactivates its heating elements and continues the program precisely where it left off.

Why This is Critical for Zirconia

Sintering is a thermally sensitive process that dictates the final physical properties of the zirconia, including its strength, translucency, and marginal fit.

An incomplete cycle or an improper restart from a cold state would introduce massive thermal stress, almost guaranteeing a fractured or warped restoration. The memory function ensures the carefully engineered heating and cooling curve is completed as intended, preserving the material's integrity.

Understanding the Limitations and Nuances

While highly effective, the power recovery feature is not a silver bullet. Understanding its limitations is key to managing your lab's operational risk.

The Duration of the Outage

The resume function is designed to handle brief to moderate power interruptions. If an outage lasts for many hours and the restoration cools significantly, resuming a high-temperature ramp could theoretically introduce thermal shock.

While the furnace controller can execute the command, the operator should use their judgment. For extremely prolonged outages, it may be safer to sacrifice the single batch rather than risk an unpredictable outcome.

Not a Substitute for Stable Power

This feature provides a safety net, but it does not replace the need for a stable electrical supply. In facilities prone to frequent brownouts or power fluctuations, the constant stopping and starting can place undue stress on the furnace's heating elements and relays over the long term.

For labs in such environments, connecting the furnace's control system (not the high-draw heating elements) to a small Uninterruptible Power Supply (UPS) can be a wise secondary precaution. This ensures the furnace's "brain" remains powered and can manage the shutdown and recovery gracefully.

Feature Varies by Model

Power failure recovery is now a standard feature on most high-quality, modern sintering furnaces. However, it may be absent on older or more basic, economy-priced models. When evaluating equipment, this should be considered a non-negotiable feature for any professional dental laboratory.

Making the Right Choice for Your Lab

This single feature directly impacts your lab's efficiency, profitability, and ability to deliver on time. Use this knowledge to guide your equipment decisions.

- If your primary focus is risk mitigation: Ensure any furnace you consider explicitly lists "power failure recovery" or "cycle resume from memory" as a key specification.

- If you operate in an area with unstable power: Treat the recovery feature as your primary defense and consider a small UPS for the furnace controller as a secondary layer of protection.

- If you are evaluating a new furnace purchase: View this feature not as a luxury, but as a fundamental requirement for protecting your investment in materials and ensuring consistent clinical outcomes.

By understanding how modern furnaces protect against power loss, you can ensure your lab's production workflow remains resilient, predictable, and shielded from costly disruptions.

Summary Table:

| Feature | Benefit |

|---|---|

| Power Failure Recovery | Resumes sintering cycle from interruption point, preventing failed batches |

| Real-Time Data Logging | Continuously records temperature, ramp rate, and time for precise recovery |

| User Control | Allows operator to confirm resumption or cancel cycle via touch screen |

| Limitations | Handles brief outages; prolonged outages may require operator judgment |

| Recommendations | Essential for labs; pair with UPS in unstable power areas for added protection |

Safeguard your dental lab's productivity and investments with KINTEK's advanced sintering solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature furnace options, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, minimizing risks from power interruptions. Contact us today to discuss how our furnaces can enhance your lab's efficiency and protect your zirconia restorations!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations