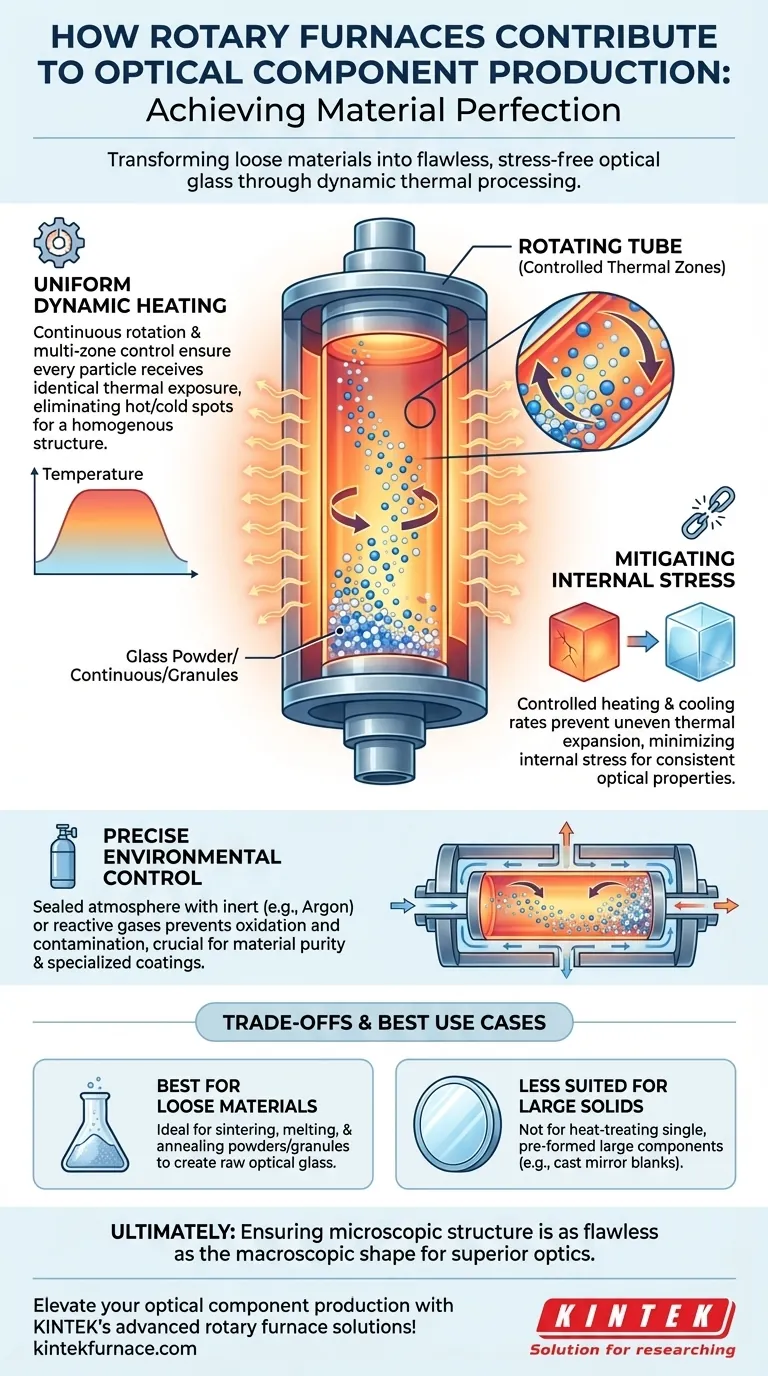

In the production of high-performance optics, rotary furnaces are indispensable for achieving the required material perfection. They contribute by subjecting materials, often in loose or powder form, to exceptionally uniform heat treatment through a combination of continuous rotation and precisely controlled thermal zones. This process is critical for creating the homogenous, stress-free glass needed for components like advanced lenses and telescope mirrors.

The core challenge in optics manufacturing is not merely shaping glass, but ensuring its internal structure is perfectly uniform. Rotary furnaces solve this by eliminating temperature gradients and internal stresses during heat treatment, guaranteeing consistent optical properties throughout the material.

The Core Principle: Uniformity Through Dynamic Heating

The value of a rotary furnace lies in its ability to treat every particle of a material in the exact same way. This dynamic approach overcomes the limitations of static furnaces where material closer to heating elements gets hotter than material in the center.

How Continuous Rotation Ensures Even Heating

A rotary furnace consists of a slowly rotating tube housed within a heating chamber. As the tube turns, the material inside (such as glass powders or granules) gently tumbles.

This constant motion ensures that no single part of the material is over-exposed or under-exposed to the heat source. It effectively averages out the temperature, preventing the hot spots and cold spots that are detrimental to optical quality.

The Role of Multiple Thermal Zones

These furnaces are not heated monolithically. They are designed with multiple, independently controlled thermal zones along the length of the tube.

This allows for a precise temperature profile. Material can be ramped up to a specific temperature, held there for an exact duration (a process known as sintering or annealing), and then cooled at a controlled rate. This level of control is fundamental for dictating the final microstructure of the glass.

Mitigating Internal Stress

When glass cools unevenly, it creates internal stresses. These stresses are invisible to the naked eye but can warp the material and, more importantly, alter its refractive index in unpredictable ways, distorting any light that passes through.

By ensuring every part of the material heats and cools at the same rate, the rotary furnace minimizes the formation of these internal stresses, resulting in a stable and optically predictable component.

Beyond Heat: Controlling the Material's Environment

Modern optical materials often require more than just precise heat. The chemical environment during processing is just as critical for achieving desired properties and purity.

Precise Control Over Gas Composition

Rotary furnaces can be sealed, allowing for complete control over the internal atmosphere. This enables advanced processes where an inert gas like argon is used to prevent oxidation.

Alternatively, a reactive gas can be introduced to cause a specific chemical transformation on the material's surface, a technique used in creating specialized optical coatings or advanced composite materials.

Ensuring Exceptional Purity

Optical performance is directly tied to material purity. Any contamination can cause absorption or scattering of light, degrading the function of a lens or mirror.

The controlled environment of a rotary furnace is crucial for preventing contaminants from the air from integrating into the material during its high-temperature, reactive state. This is similar to the principle behind vacuum furnaces, where the goal is to create the purest material possible.

Understanding the Trade-offs

While powerful, rotary furnaces are a specific tool for specific applications. Understanding their limitations is key to using them effectively.

Best Suited for Loose Materials

Rotary furnaces are designed to process powders, granules, or other "loose" materials. They are the ideal choice for creating the raw optical glass itself from its constituent ingredients.

They are generally not used for heat-treating a single, large, pre-formed solid, such as a large mirror blank that has already been cast. Such components are typically annealed in large, custom-built static furnaces.

Mechanical Complexity and Cost

The addition of a rotating drive system, high-integrity seals, and multi-zone controllers makes these systems more mechanically complex and expensive than a simple box furnace.

This cost is justified by the exceptional uniformity and high throughput required for producing advanced optical materials at scale.

Making the Right Choice for Your Goal

The decision to use a rotary furnace is driven by the need for absolute control over a material's fundamental properties during thermal processing.

- If your primary focus is producing raw optical glass from powders: A rotary furnace is the superior choice for sintering or melting ingredients into a perfectly homogenous blank.

- If your primary focus is creating stress-free components: The uniform heating and controlled cooling of a rotary furnace are essential for annealing and eliminating internal stresses that degrade optical performance.

- If your primary focus is developing novel optical materials: The ability to precisely manage both the thermal profile and gaseous atmosphere makes the rotary furnace an invaluable tool for research and development.

Ultimately, employing a rotary furnace is a strategic decision to ensure the microscopic structure of the material is as flawless as the macroscopic shape of the final optic.

Summary Table:

| Aspect | Contribution |

|---|---|

| Uniform Heating | Continuous rotation eliminates temperature gradients for homogenous material structure. |

| Stress Reduction | Controlled thermal zones minimize internal stresses, ensuring stable optical properties. |

| Environmental Control | Sealed atmosphere with inert or reactive gases prevents contamination and enables chemical transformations. |

| Material Suitability | Ideal for powders and granules in sintering, annealing, and melting processes for optical glass. |

Elevate your optical component production with KINTEK's advanced rotary furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Rotary, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, guaranteeing superior material uniformity and performance. Contact us today to discuss how we can optimize your thermal processing for flawless optics!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity