In the metal industry, muffle furnaces are fundamentally used for high-precision heat treatment processes. They are essential tools for altering the microstructure and mechanical properties of metals through applications like hardening, annealing, tempering, sintering, and brazing, where precise temperature and atmospheric control are non-negotiable.

The core value of a muffle furnace in metallurgy is its ability to isolate the metal workpiece from the direct heat source and ambient air. This separation creates a highly controlled, uniform thermal environment, preventing contamination and enabling the precise structural changes required to achieve desired material properties.

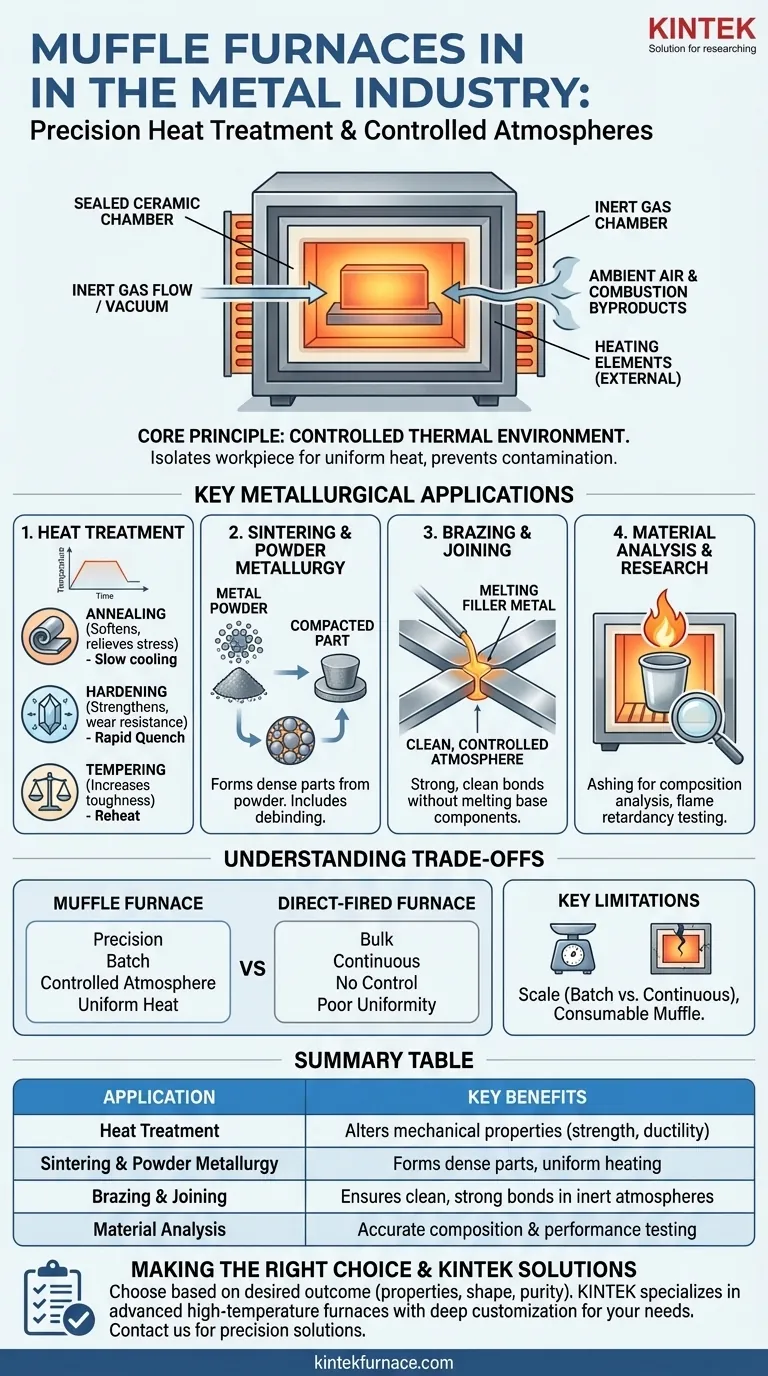

The Core Principle: A Controlled Thermal Environment

The defining feature of a muffle furnace is the muffle—a sealed inner chamber, typically made of ceramic, that contains the workpiece. The heating elements are located outside this chamber.

Isolating the Workpiece

This design isolates the metal part from the byproducts of combustion (in fuel-fired models) and from direct radiation from the heating elements. This prevents surface scaling, oxidation, and other unwanted chemical reactions.

Enabling Atmospheric Control

Because the muffle is a sealed chamber, the atmosphere inside can be carefully controlled. It can be held under a vacuum or filled with a specific gas (like nitrogen or argon) to create an inert environment, which is critical for processing reactive metals or ensuring a clean surface finish.

Key Metallurgical Applications

The precise control offered by muffle furnaces makes them indispensable for several critical processes that define the final characteristics of a metal component.

Heat Treatment for Mechanical Properties

Heat treatment involves carefully controlled heating and cooling cycles to change a metal's physical and mechanical properties.

- Annealing: Metals are heated to a specific temperature and then cooled slowly. This process softens the metal, increases its ductility, and relieves internal stresses, making it easier to work with.

- Hardening: Steel and other alloys are heated to a high temperature and then rapidly cooled (quenched). This locks in a hard, brittle crystalline structure, dramatically increasing the material's strength and wear resistance.

- Tempering: Following hardening, the brittle component is reheated to a lower temperature. This process reduces some of the hardness and brittleness, improving the material's overall toughness.

Sintering and Powder Metallurgy

Sintering is the process of taking compacted metal powder and heating it to just below its melting point.

The uniform heat of a muffle furnace causes the powder particles to bond together, forming a solid, dense part. This is a cornerstone of powder metallurgy and is used to create complex, net-shape components from materials like stainless steel and other alloys. A related process, debinding, is also done in these furnaces to remove binder materials from "green" parts made via Metal Injection Molding (MIM).

Brazing and High-Purity Joining

Brazing is a joining process where a filler metal with a lower melting point is used to bond two metal components.

A muffle furnace provides an ideal environment for brazing because the clean, controlled atmosphere prevents oxidation of the joint surfaces. This ensures the filler metal wets and flows properly, creating a strong, clean, and reliable bond without melting the base components.

Material Analysis and Research

In metallurgical labs, muffle furnaces are used for analytical tasks. This includes ashing, where a metal sample is burned to determine its composition by analyzing the non-combustible residue. They are also used in the aerospace and other sectors to test the flame retardancy and high-temperature performance of metals and coatings.

Understanding the Trade-offs

While powerful, muffle furnaces are not a universal solution. Understanding their specific advantages compared to other furnace types is key.

Muffle Furnace vs. Direct-Fired Furnace

A direct-fired furnace exposes the material directly to the heat source and combustion gases. This method is often faster and more economical for bulk heating, such as melting large quantities of scrap metal in a foundry.

However, it offers poor temperature uniformity and no atmospheric control, making it unsuitable for the precision heat treatments where a muffle furnace excels. The choice depends on whether the goal is simple melting or precise property modification.

Key Limitations

The primary limitation of a muffle furnace is often scale. While large industrial models exist, they are generally used for batch processing of high-value components rather than the continuous, high-volume throughput seen with large industrial belt furnaces. The muffle itself is also a consumable component that can degrade or crack over time, especially with rapid temperature changes or extreme high temperatures.

Making the Right Choice for Your Goal

Selecting the correct thermal process is dictated entirely by the desired outcome for your metal component.

- If your primary focus is altering mechanical properties (strength, ductility): A muffle furnace is essential for the precise heating and cooling cycles required for annealing, hardening, and tempering.

- If your primary focus is creating complex net-shape parts from powder: The uniform heat and controlled atmosphere of a muffle furnace are ideal for reliable sintering and MIM debinding.

- If your primary focus is high-purity joining or material analysis: The clean, isolated environment of a muffle furnace is non-negotiable for quality brazing and accurate compositional testing.

Ultimately, mastering the use of a muffle furnace gives you direct control over the very microstructure that defines a metal's performance.

Summary Table:

| Application | Key Benefits |

|---|---|

| Heat Treatment (Annealing, Hardening, Tempering) | Alters mechanical properties like strength and ductility |

| Sintering and Powder Metallurgy | Forms dense parts from metal powders with uniform heating |

| Brazing and Joining | Ensures clean, strong bonds in inert atmospheres |

| Material Analysis | Provides accurate testing for composition and performance |

Ready to elevate your metal processing with precision and reliability? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring optimal performance for heat treatment, sintering, and more. Contact us today to discuss how we can enhance your laboratory's capabilities and drive your innovations forward!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure