You’ve done everything by the book. The precursors are pure, the calculations are double-checked, and the protocol is followed to the letter. You spend days setting up a critical sintering or annealing run. Yet, when you open the furnace, the result is another failure: a cracked ceramic, a film with poor adhesion, or material properties that are all over the map. You’re left staring at the sample, asking the same frustrating question: "What went wrong this time?"

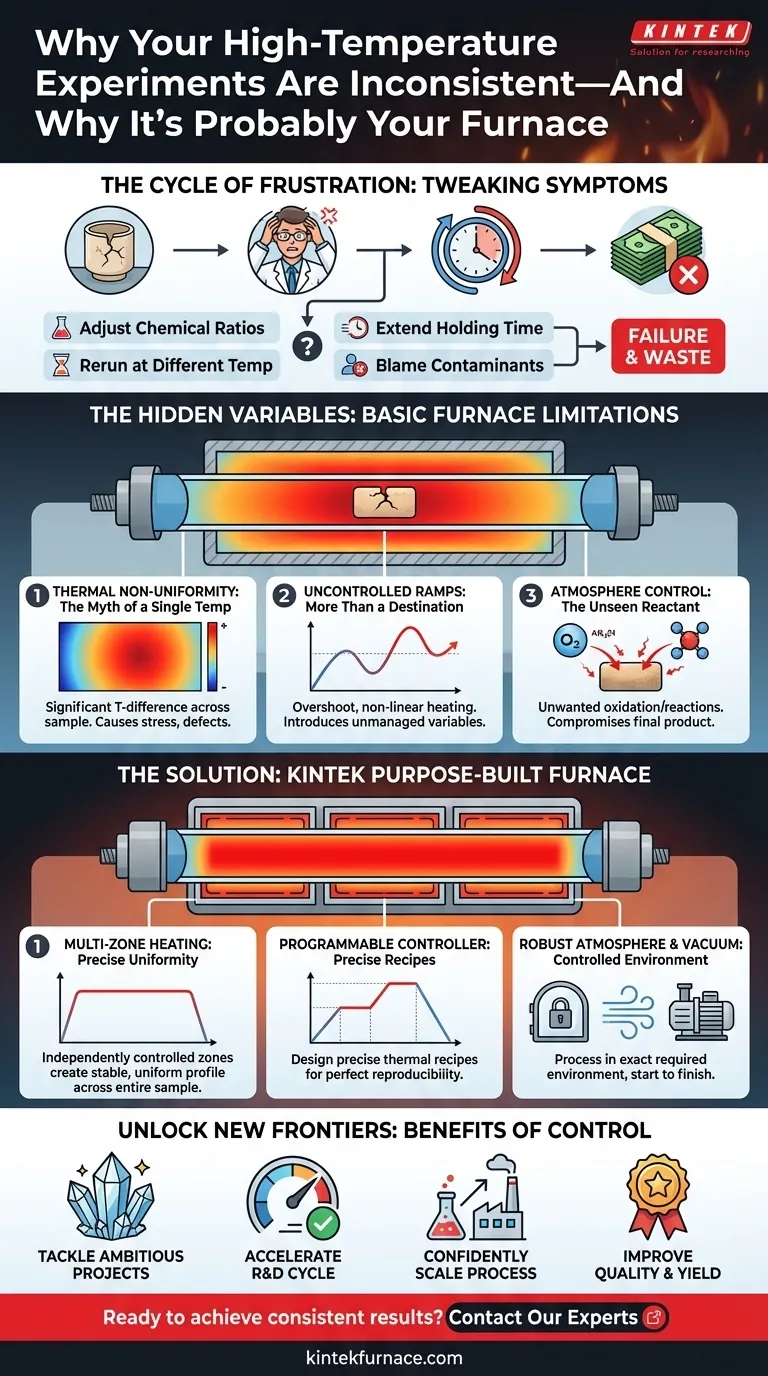

The Cycle of Frustration: Tweaking Everything But the Real Problem

If this scenario sounds familiar, you're not alone. In materials science labs and advanced manufacturing facilities worldwide, inconsistent thermal processing is a notorious bottleneck. When an experiment fails, the typical response is to look at the most immediate variables.

We might:

- Adjust the chemical ratios of the starting materials.

- Rerun the experiment at a slightly different peak temperature.

- Extend the holding time, hoping for better results.

- Blame an unknown contaminant or a faulty gas line.

Each attempt consumes valuable time, expensive materials, and team morale. The commercial consequences are severe: project deadlines are missed, R&D budgets are wasted on repeated work, and promising innovations fail to move from the lab to production because the process simply isn't reliable.

But what if the problem isn’t with your materials or your protocol? What if the "common solutions" are failing because they are addressing the symptoms, not the disease? The real issue often lies hidden in plain sight: the fundamental limitations of a standard furnace.

The Hidden Variable: Your Furnace Isn't Just a Box That Gets Hot

The core conflict between expectation and reality is this: we treat the furnace as a simple device that provides a stable, uniform temperature, but the physical reality inside a basic furnace is far more chaotic. The true root cause of inconsistency isn't a single factor, but a lack of control over the entire thermal environment.

The Myth of a Single Temperature: Thermal Uniformity

A standard tube furnace with a single heating element does not create a perfectly uniform hot zone. Instead, it creates a temperature gradient, much like a campfire being hottest at the center and cooler at the edges. If your sample has any significant length, one end could be 10-20°C hotter than the other. For sensitive processes like crystal growth or annealing, this temperature difference is enough to create internal stresses, defects, and completely ruin your results. This is why you can run the same experiment twice and get different outcomes by simply placing the sample a few centimeters to the left or right.

More Than a Destination: The Importance of the Journey (Heating Ramps)

We often focus only on the target temperature (e.g., 1200°C), but how the furnace gets there—the heating and cooling ramps—is equally critical. A basic controller might overshoot the target temperature, causing thermal shock, or heat up non-linearly. Without precise, repeatable control over these ramps, you are introducing a massive, unmanaged variable into every single experiment. The "solutions" of tweaking holding times often fail because the damage was already done during the uncontrolled journey to the peak temperature.

The Unseen Reactant: Atmosphere Control

Unless you are operating in a high vacuum, the atmosphere inside the furnace—even if it's just air—is a chemical reactant. For many advanced materials, unwanted oxidation or reactions with trace gases can compromise the final product. Simply flowing an inert gas isn't enough; you need to ensure a controlled, stable environment throughout the entire process.

Moving from Guesswork to Control: The Anatomy of a Purpose-Built Furnace

To overcome these fundamental physical challenges, you don't need to work harder; you need a more intelligent tool. The solution is not just a "better" furnace, but one specifically engineered to manage these hidden variables. This is where a furnace designed with a deep understanding of thermal processing physics makes all the difference.

A truly advanced furnace is defined by its ability to deliver precise control:

- To solve the problem of non-uniformity, it uses multi-zone heating. With two, three, or more independently controlled heating zones, it can create a long, exceptionally stable, and uniform temperature profile across your entire sample. This eliminates the guesswork of sample placement.

- To solve the problem of inconsistent ramps, it employs a multi-segment programmable controller. This allows you to design a precise thermal "recipe"—dictating the exact heating rate, holding time, and cooling rate for dozens of steps. It executes this recipe perfectly every time, ensuring absolute reproducibility.

- To solve the problem of atmospheric contamination, it integrates robust vacuum and atmosphere control systems. This ensures your material is processed in the exact environment it requires, from start to finish.

KINTEK's furnace solutions are not just a collection of features; they are the direct answer to the root causes of experimental failure. We designed them based on the principles of thermal dynamics to give researchers and engineers the control they have been missing.

Beyond Reproducibility: What New Frontiers Can You Explore?

When you finally solve the problem of process inconsistency, you do more than just save time and materials. You unlock entirely new possibilities.

With a furnace that delivers precise, reliable control, you can:

- Tackle more ambitious projects, like growing larger, defect-free single crystals or developing next-generation composite materials that were previously too sensitive to process.

- Accelerate your R&D cycle by moving from one successful experiment to the next with confidence, rather than being stuck in a loop of troubleshooting.

- Confidently scale your process from the lab to pilot production, knowing that the thermal conditions can be replicated perfectly.

- Improve product quality and yield, establishing a reputation for reliability and excellence in your field.

Ultimately, gaining control over your thermal process isn't just about fixing a nagging problem; it's about removing a fundamental barrier to innovation. It allows you to focus on the science, not on the struggle with your equipment.

Your research is too important to be derailed by hidden variables. If you're ready to move past the cycle of frustration and achieve the consistent, high-quality results your work demands, our team is here to help you configure a solution tailored to your exact needs. Let's discuss the unique challenges of your project and how the right tools can help you overcome them. Contact Our Experts.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

Related Articles

- Beyond the Program: Why Your Sintering Fails and How to Guarantee Uniformity

- Cracked Crucibles, Inconsistent Data? The Post-Heating Step You're Missing

- Why Your High-Temperature Synthesis Results Are Unreliable—And How to Fix It

- Why Your Thermal Processing Fails: The Hidden Mismatch in Your Furnace

- The Hidden Saboteur in Your High-Temperature Furnace: Why Your Melts Are Inconsistent—And How to Fix It