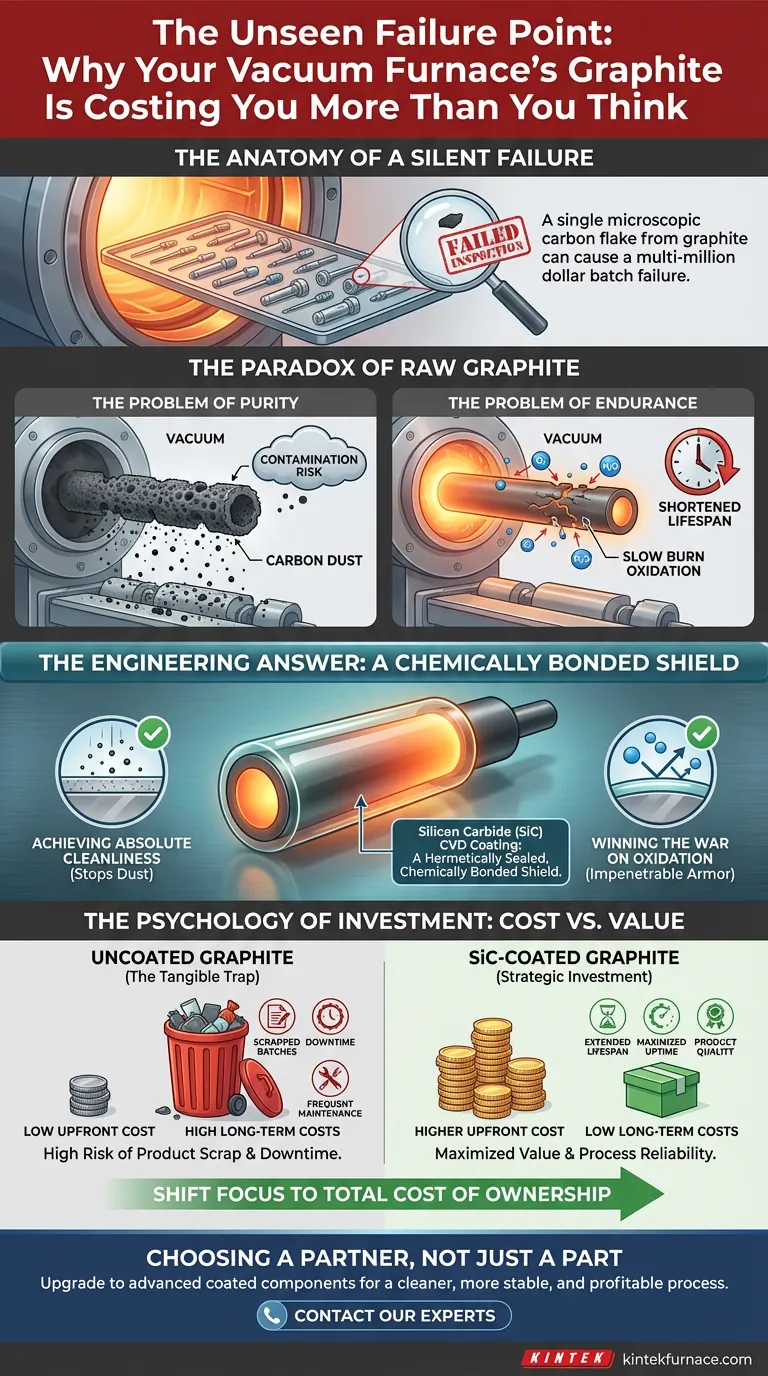

The Anatomy of a Silent Failure

Imagine a multi-million dollar batch of medical implants being heat-treated in a vacuum furnace. The process parameters are perfect, the vacuum is deep, and the metallurgy is precise.

Yet, the batch fails inspection. The cause? A single, microscopic carbon flake, shed from a graphite heating element, landed on a critical surface, creating a point of weakness.

This isn't a dramatic equipment failure. It's a silent, insidious one, rooted in a material we trust for its high-temperature strength: graphite. The problem isn't the material itself, but our acceptance of its inherent flaws.

The Paradox of Raw Graphite

Graphite is an engineering marvel. Its ability to maintain structural integrity at temperatures that would melt most metals makes it an obvious choice for furnace components like heating elements, fixtures, and insulation.

But this strength hides a fundamental paradox. The very material that creates the heat can also poison the purity of the process.

The Problem of Purity: A Constant Rain of Dust

Uncoated graphite is porous and relatively soft. Under vacuum and thermal cycling, it constantly sheds fine carbon particles.

This phenomenon, known as "dusting," creates a continuous rain of contamination inside the furnace. For high-purity industries like semiconductors, aerospace, and medical devices, this isn't a nuisance; it's a critical failure point that can render an entire product run worthless.

The Problem of Endurance: A Slow Burn

Even in a high vacuum, trace amounts of oxygen and water vapor persist. At extreme temperatures, these residual gases are not passive bystanders; they are highly aggressive attackers.

They react with the graphite surface in a process of slow-burn oxidation. This erosion gradually weakens components, shortening their lifespan and forcing costly, frequent maintenance cycles. It's a constant battle against material entropy.

The Engineering Answer: A Chemically Bonded Shield

The solution is not to abandon graphite, but to perfect it. This is achieved not with a simple paint, but with a fundamentally new surface created by depositing a dense, non-porous layer of Silicon Carbide (SiC) through a Chemical Vapor Deposition (CVD) process.

This isn't just a coating; it's a hermetically sealed, chemically bonded shield that transforms the component.

Achieving Absolute Cleanliness

The hard, sealed surface of the SiC coating completely locks the graphite particles in place. The "rain of dust" stops.

This single improvement elevates the furnace from a standard heat-treating tool to a high-purity processing environment, ensuring product quality and process repeatability.

Winning the War on Oxidation

The SiC shield is exceptionally inert and far more resistant to oxidation than the graphite it protects. It acts as impenetrable armor, preventing corrosive gases from ever reaching the graphite substrate.

The result is a dramatic extension in the life of heating elements, racks, and fixtures, turning a consumable part into a durable, long-term asset.

The Psychology of Investment: Cost vs. Value

The most common hesitation in adopting coated components is the higher upfront price. This is a classic psychological trap: the battle between immediate cost and long-term value.

The Bias for the Tangible

We are psychologically wired to react to immediate, tangible numbers—the price on an invoice. We tend to discount future, less-visible costs like:

- The labor hours spent on component replacement.

- The value of lost production during furnace downtime.

- The staggering cost of a single scrapped batch due to contamination.

Recalculating the Equation: Total Cost of Ownership

Viewing coated components as a strategic investment in reliability changes the entire financial equation. The value isn't in the part itself, but in the problems it prevents.

| Component Choice | Upfront Cost | Long-Term Operational Costs |

|---|---|---|

| Uncoated Graphite | Low | High: Frequent replacement, maintenance labor, furnace downtime, risk of product scrap. |

| SiC-Coated Graphite | Higher | Low: Extended lifespan, minimal maintenance, maximized uptime, protected product quality. |

The decision shifts from "How much does this part cost?" to "How much will this part save me?"

Choosing a Partner, Not Just a Part

The effectiveness of this solution hinges entirely on the quality of the coating. A poorly applied coating can crack or delaminate under the stress of rapid thermal cycles, negating its benefits.

This is why your choice of supplier is critical. You need a partner with deep expertise in both materials science and advanced manufacturing processes.

At KINTEK, our foundation in R&D and in-house manufacturing allows us to engineer and produce SiC-coated graphite components that deliver unparalleled performance and reliability. Because we control the entire process, our deep customization capabilities ensure that every component—from heating elements to complex fixtures—is perfectly tailored to your furnace's specific thermal cycles and your unique process requirements.

Upgrading to advanced coated components is a strategic shift from fighting a material's inherent flaws to unlocking its full potential. It's about building a cleaner, more stable, and ultimately more profitable process.

To explore how high-performance coated graphite can enhance your operations, Contact Our Experts.

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

Related Articles

- Beyond Heat: How Graphite's Physics Enables Precision in Vacuum Furnaces

- Beyond the Heat: The Psychology of Perfect Vacuum Furnace Operation

- The Unseen Engine: Why Graphite Dominates High-Temperature Vacuum Furnaces

- More Than a Void: The Inherent Energy Efficiency of Vacuum Furnace Design

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny