The Unseen Cost of Gradual Failure

An experienced engineer notices something subtle. A vacuum cycle that used to take 45 minutes now edges toward 55. The power draw for a standard heat treat recipe seems a fraction higher this month.

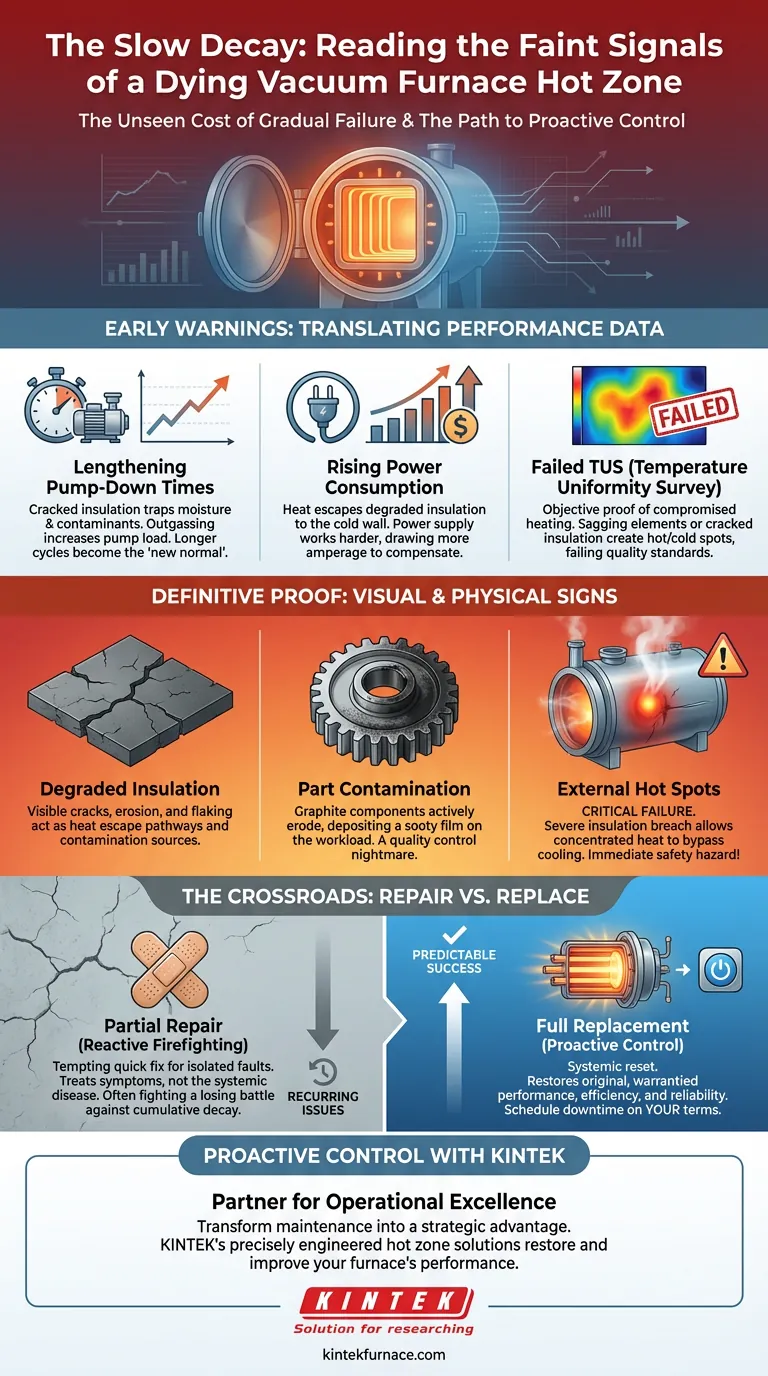

The human mind is brilliant at adaptation. We get used to these small changes. We call it the "new normal." In high-risk fields, this is known as the normalization of deviance. We subconsciously accept a slightly lower standard of performance until, one day, a catastrophic failure makes the gradual decline obvious in retrospect.

A vacuum furnace's hot zone—its very heart—rarely fails in an instant. Instead, it whispers its decay through data and subtle physical clues. Learning to interpret this language is the difference between controlling your process and being a victim of it.

The Anatomy of a Crucible

At its core, a hot zone is a controlled universe. It's an insulated chamber, typically built from graphite or refractory metals like molybdenum, designed to generate and contain immense heat with incredible uniformity. Within this space, materials are transformed.

But the very conditions that enable this transformation also ensure the hot zone's eventual demise.

Every thermal cycle forces materials to expand and contract. Over thousands of cycles, metallic heating elements can warp and become brittle. Graphite insulation boards can crack, and the binder that holds them together can outgas, slowly eroding their structure. This isn't a design flaw; it is the fundamental physics of operating at the extremes.

Translating Performance Data into Physical Reality

The earliest warnings of decay are not seen, but measured. Your furnace's performance logs are a running commentary on the health of its hot zone.

The Lengthening Shadow: Pump-Down Times

When insulation begins to crack and degrade, its surface area increases, and it traps more atmospheric moisture and contaminants when the furnace is open. During the next cycle, this trapped material outgasses, creating a higher load on the vacuum pumps.

The result is a progressively longer pump-down time. It's a classic symptom that is easy to blame on the pumps themselves, but often, the problem lies deeper within the chamber.

The Energy Bill's Silent Scream: Power Consumption

A healthy hot zone is a masterpiece of thermal efficiency. As its insulation fails, that efficiency bleeds away. Heat escapes the work area and radiates to the cold wall of the furnace vessel, where it is carried away by the cooling water.

Your power supply must now work harder, drawing more amperage to compensate for this constant heat loss. The furnace is fighting itself to maintain temperature, and the cost of that battle appears directly on your energy bill.

The Unambiguous Verdict: A Failed Temperature Uniformity Survey (TUS)

A failed TUS is the point where suspicion becomes documented fact. It is objective proof that the hot zone can no longer deliver the even, consistent heating required for quality parts.

This is often caused by sagging elements creating hot spots or cracked insulation creating cold spots. For any quality-critical application, from aerospace to medical, a TUS failure is a non-negotiable signal that the system's integrity is compromised.

When the Furnace Speaks Through Sight and Touch

While data provides early warnings, a visual inspection offers definitive proof. These are the signs that you can no longer ignore.

The Cracks in the Armor: Degraded Insulation

Opening the furnace to find cracked, flaking, or eroded insulation boards is the most direct evidence of decay. Each crack is a pathway for heat to escape and a source of potential contamination.

The Unwanted Signature: Part Contamination

Finding a black, sooty film of graphite on your finished parts is a quality control nightmare. It means the graphite components of the hot zone—the elements or the insulation—are actively eroding and depositing themselves onto your workload. The problem has officially escaped the furnace and entered your product.

The Red Flag: External Hot Spots

If you can feel a warm or hot spot on the outer, water-cooled shell of your furnace, you have a critical failure. This signifies a severe breach in the insulation pack, allowing a concentrated stream of heat to bypass the cooling system. It is a direct threat to the equipment and a significant safety hazard that demands an immediate shutdown and inspection.

The Crossroads: The Psychology of Repair vs. Replace

Faced with a failing hot zone, the temptation is to seek a simple fix. We are psychologically wired to prefer a small, immediate solution over a larger, planned one.

A partial repair—replacing a single broken element or patching a cracked board—can seem cost-effective. And for a relatively new hot zone with one isolated fault, it may be the right call.

However, when you face multiple, systemic symptoms—longer pump times, higher power use, and visible degradation—a repair is merely treating a symptom of a larger disease. You are fighting a losing battle. A full hot zone replacement is a systemic reset. It restores the furnace to its original, warrantied performance, giving you a predictable, reliable, and efficient system once again.

From Reactive Firefighting to Proactive Control

Understanding the language of a failing hot zone transforms maintenance from a reactive crisis into a strategic advantage. It allows you to schedule downtime on your terms, not on the furnace's.

Ensuring this level of control requires not just knowledge, but a reliable partner. The first step is recognizing the signs; the next is implementing a robust solution. KINTEK's expertise in R&D and manufacturing of high-temperature systems, including fully customizable Vacuum Furnaces, provides the foundation for operational excellence. A replacement hot zone from KINTEK isn't just a component; it's a precisely engineered solution designed to restore and often improve your furnace's original performance.

Don't wait for a failure to dictate your production schedule. Take control of your process. Contact Our Experts

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

Related Articles

- The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites

- Beyond the Heat: The Psychology of Perfect Vacuum Furnace Operation

- Your Vacuum Furnace Is a System, Not a Component—Here’s Why That Changes Everything

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny