The Pursuit of an Unseen Enemy

In materials science, the greatest challenge isn't always what you add. It's what you fail to remove.

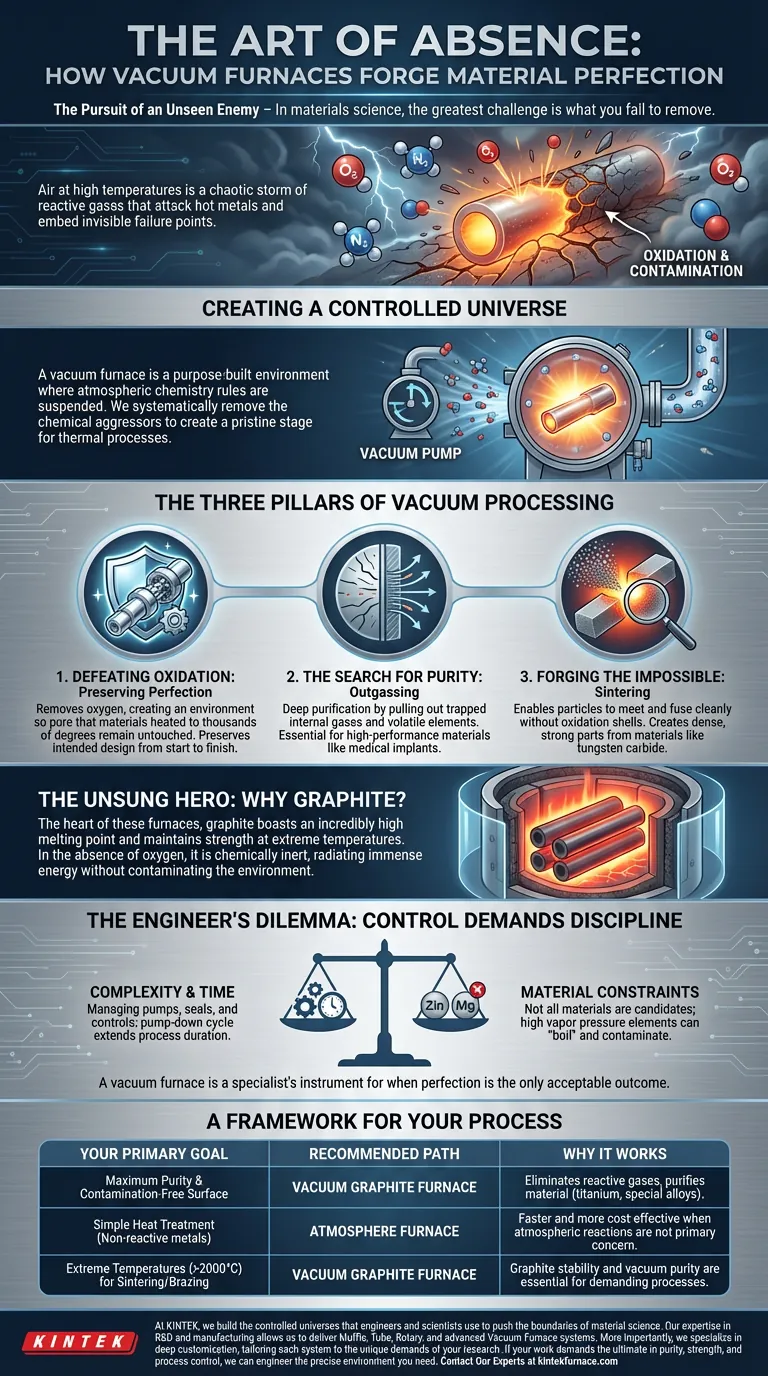

The air around us feels benign, but at high temperatures, it becomes a chaotic storm of reactive gases. Oxygen, the element that gives us life, aggressively attacks hot metals, creating a brittle layer of oxide. Nitrogen and other trace gases embed themselves into a material's structure, creating invisible points of failure.

The desire to heat a material is a desire to change it. The desire to do so in a vacuum is a desire for absolute control over that change.

Creating a Controlled Universe

A vacuum furnace isn't just a hot box. It's a purpose-built environment where the rules of atmospheric chemistry are suspended.

Its primary function is not simply heating, but creating a pristine stage for thermal processes. By pumping out the air, we're not creating emptiness. We are systematically removing the variables—the chemical aggressors—that would otherwise compromise the integrity of our work.

This control is the foundation for achieving material properties impossible in any other environment.

The Three Pillars of Vacuum Processing

Achieving this control unlocks three distinct advantages that redefine what's possible in material engineering.

1. Defeating Oxidation: Preserving Perfection

Imagine a complex component, machined to micron-level precision. When heated in air, its perfect surface is instantly tarnished. Oxidation creates a scale that ruins tolerances and degrades the material's surface.

A vacuum furnace physically removes the oxygen. It creates an environment so pure that the material can be heated to thousands of degrees without fear of this chemical assault. It’s about preserving the intended design from start to finish.

2. The Search for Purity: Outgassing

The vacuum’s power goes deeper than just surface protection.

As a material heats up under vacuum, trapped internal gases and volatile elements are literally pulled out from its core. This process, known as outgassing, is a deep purification. It’s how you turn a standard alloy into a high-performance material suitable for a medical implant or a critical aerospace turbine blade, where the presence of a single impurity could be catastrophic.

3. Forging the Impossible: Sintering

Certain processes are simply non-negotiable; they require a vacuum.

Consider sintering, the process of fusing fine metal powders into a solid object. In the open air, each microscopic particle would instantly oxidize, forming a chemical shell that prevents it from bonding with its neighbors.

In a vacuum, these particles are naked. They meet and fuse cleanly, creating a dense, strong, and homogenous final part from materials like tungsten carbide or specialty steels. The vacuum makes their union possible.

The Unsung Hero: Why Graphite?

The heart of these furnaces—the heating elements and insulation—is made of graphite. This is a deliberate, critical choice.

Graphite boasts an incredibly high melting point and maintains its strength at temperatures that would vaporize most metals. It becomes the steadfast scaffold that contains the extreme heat.

More importantly, in the absence of oxygen, graphite is chemically inert. It radiates immense energy without reacting with or contaminating the pristine environment it helps create. It is the silent, stable guardian of the process.

The Engineer's Dilemma: Control Demands Discipline

This level of control is not without its trade-offs. It represents a commitment to a more complex and deliberate process.

- Complexity: Operating a vacuum furnace requires managing pumps, seals, and sophisticated controls. It demands a higher level of operational discipline.

- Time: Pulling a vacuum takes time. The pump-down cycle extends the overall process duration, a necessary investment for the quality achieved.

- Material Constraints: Not all materials are candidates. Elements with high vapor pressure (like zinc or magnesium) can "boil" under vacuum at high temperatures, contaminating the furnace and destroying the part.

Understanding these trade-offs is key. A vacuum furnace is not a universal tool; it is a specialist's instrument for when perfection is the only acceptable outcome.

A Framework for Your Process

Choosing the right thermal technology hinges on your ultimate goal.

| Your Primary Goal | Recommended Path | Why It Works |

|---|---|---|

| Maximum Purity & Contamination-Free Surface | Vacuum Graphite Furnace | Eliminates reactive gases, purifies the material, essential for titanium, special alloys. |

| Simple Heat Treatment (Non-reactive metals) | Atmosphere Furnace | Faster and more cost-effective when atmospheric reactions are not a primary concern. |

| Extreme Temperatures (>2000°C) for Sintering/Brazing | Vacuum Graphite Furnace | Graphite's stability and vacuum's purity are essential for these demanding processes. |

At KINTEK, we build the controlled universes that engineers and scientists use to push the boundaries of material science. Our expertise in R&D and manufacturing allows us to deliver Muffle, Tube, Rotary, and advanced Vacuum Furnace systems. More importantly, we specialize in deep customization, tailoring each system to the unique demands of your research.

If your work demands the ultimate in purity, strength, and process control, we can engineer the precise environment you need. Contact Our Experts

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

Related Articles

- The Unseen Enemy: How Vacuum Furnaces Redefine Material Perfection

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection

- More Than a Void: The Inherent Energy Efficiency of Vacuum Furnace Design

- The Unseen Enemy: Why Vacuum Furnaces Are a Bet on Perfection

- From Brute Force to Perfect Control: The Physics and Psychology of Vacuum Furnaces