At its core, PECVD is a cornerstone of modern high-volume manufacturing because it uniquely combines efficiency, versatility, and low processing temperatures. This allows it to deposit uniform, high-quality thin films over large areas without damaging the sensitive, pre-existing components on a substrate. It is this low-temperature capability that unlocks its suitability for producing complex, multi-layered electronics at scale.

The true value of PECVD in large-scale manufacturing isn't just about depositing films; it's the ability to do so at low temperatures. This single attribute enables the creation of sophisticated devices like modern microchips and displays, which would be destroyed by the heat of traditional deposition methods.

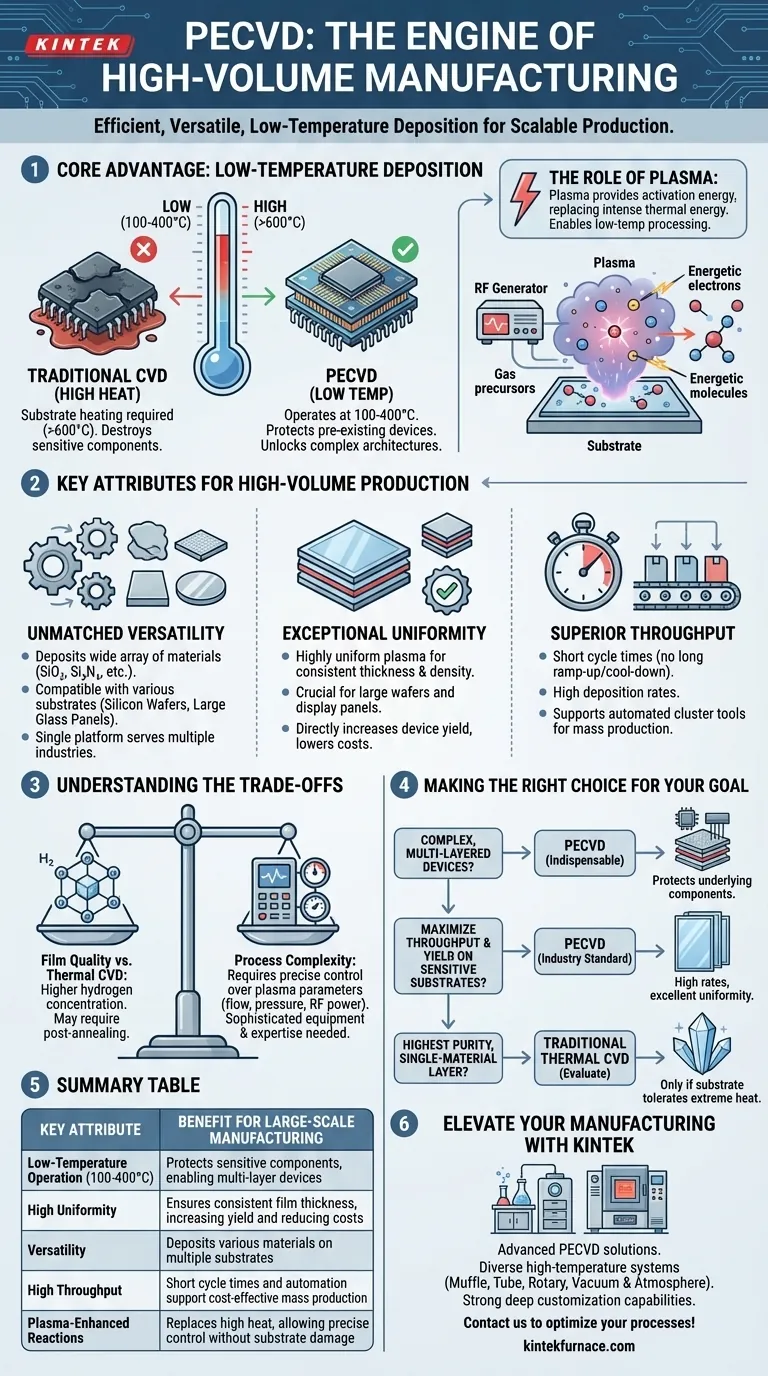

The Fundamental Advantage: Low-Temperature Deposition

The defining characteristic of Plasma-Enhanced Chemical Vapor Deposition (PECVD) is its use of plasma to drive the chemical reactions needed for film growth, rather than relying solely on high heat. This fundamentally alters what is possible in a manufacturing environment.

Why Low Temperature is a Game-Changer

In traditional Chemical Vapor Deposition (CVD), substrates must be heated to very high temperatures (often >600°C) to provide the thermal energy needed to break down precursor gases and form a film.

This high heat is destructive to many modern electronic devices. Components like transistors, metal interconnects, or organic materials fabricated in earlier steps cannot survive such temperatures, making traditional CVD unsuitable for many critical process steps.

PECVD operates at much lower temperatures, typically in the range of 100-400°C. This allows for the deposition of essential films on top of fully formed, complex device architectures without causing damage or altering their performance.

The Role of Plasma

In a PECVD system, an electromagnetic field (usually radio frequency) is used to ionize the precursor gases, creating a low-temperature plasma.

This plasma contains highly energetic electrons and ions. Collisions between these energetic particles and the neutral gas molecules provide the energy required to break chemical bonds and initiate the deposition reaction on the substrate surface.

Essentially, the plasma provides the activation energy, replacing the need for intense thermal energy. This is the key mechanism that makes low-temperature processing possible.

Key Attributes for High-Volume Production

Beyond its low-temperature advantage, PECVD possesses several other characteristics that make it ideal for mass manufacturing.

Unmatched Versatility

PECVD can deposit a wide array of materials, including crucial dielectrics like silicon dioxide (SiO₂) and silicon nitride (Si₃N₄).

The process is compatible with various substrates, from the silicon wafers used in microchip fabrication to the large glass panels used for flat-panel displays. This flexibility allows a single technology platform to serve multiple industries.

Exceptional Uniformity

For any device to function reliably, its layers must have a consistent thickness and density across the entire surface. This is especially true for large silicon wafers or display panels where thousands or millions of individual devices are made at once.

PECVD systems are engineered to provide highly uniform plasma, resulting in films with excellent thickness and property consistency over very large areas. This directly translates to higher device yield and lower manufacturing costs.

Superior Throughput and Efficiency

Because the process does not require long ramp-up and cool-down times associated with high-temperature furnaces, PECVD cycle times are relatively short.

This high deposition rate, combined with the ability to process large substrates in automated cluster tools, results in the high throughput necessary for cost-effective, large-scale manufacturing.

Understanding the Trade-offs

While powerful, PECVD is not a perfect solution for every scenario. Understanding its limitations is crucial for making informed engineering decisions.

Film Quality vs. Thermal CVD

Films deposited via PECVD often contain a higher concentration of hydrogen compared to their high-temperature counterparts. This hydrogen is incorporated from the precursor gases (like silane, SiH₄) and can sometimes affect the film's electrical properties or long-term stability.

For applications demanding the absolute highest film purity and density, high-temperature thermal processes may still be preferred, but only if the substrate can tolerate the heat. Often, a post-deposition annealing step is used to drive out hydrogen from PECVD films.

Process Complexity

The physics of plasma is inherently complex. Controlling the film's properties—such as stress, density, and chemical composition—requires precise control over numerous parameters like gas flow, pressure, RF power, and frequency.

This requires sophisticated and expensive equipment, as well as significant process engineering expertise to maintain stable, repeatable results in a high-volume environment.

Making the Right Choice for Your Goal

Selecting the right deposition technology depends entirely on your manufacturing priorities and device requirements.

- If your primary focus is creating complex, multi-layered devices: PECVD is indispensable due to its low-temperature processing, which protects underlying components like transistors and metal layers.

- If your primary focus is maximizing production throughput and yield for devices on temperature-sensitive substrates: PECVD's combination of high deposition rates and excellent uniformity over large areas makes it the industry standard.

- If your primary focus is achieving the highest possible material purity for a simple, single-material layer: You may evaluate traditional thermal CVD, but only if your substrate can withstand the extreme heat without damage.

Ultimately, PECVD empowers large-scale manufacturing by enabling the deposition of critical films where high temperatures are simply not an option.

Summary Table:

| Key Attribute | Benefit for Large-Scale Manufacturing |

|---|---|

| Low-Temperature Operation (100-400°C) | Protects sensitive components, enabling multi-layer devices |

| High Uniformity | Ensures consistent film thickness, increasing yield and reducing costs |

| Versatility | Deposits various materials (e.g., SiO₂, Si₃N₄) on multiple substrates |

| High Throughput | Short cycle times and automation support cost-effective mass production |

| Plasma-Enhanced Reactions | Replaces high heat, allowing precise control without substrate damage |

Elevate your manufacturing with KINTEK's advanced PECVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet unique experimental requirements. Contact us today to discuss how our expertise can optimize your large-scale production processes and deliver superior results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition