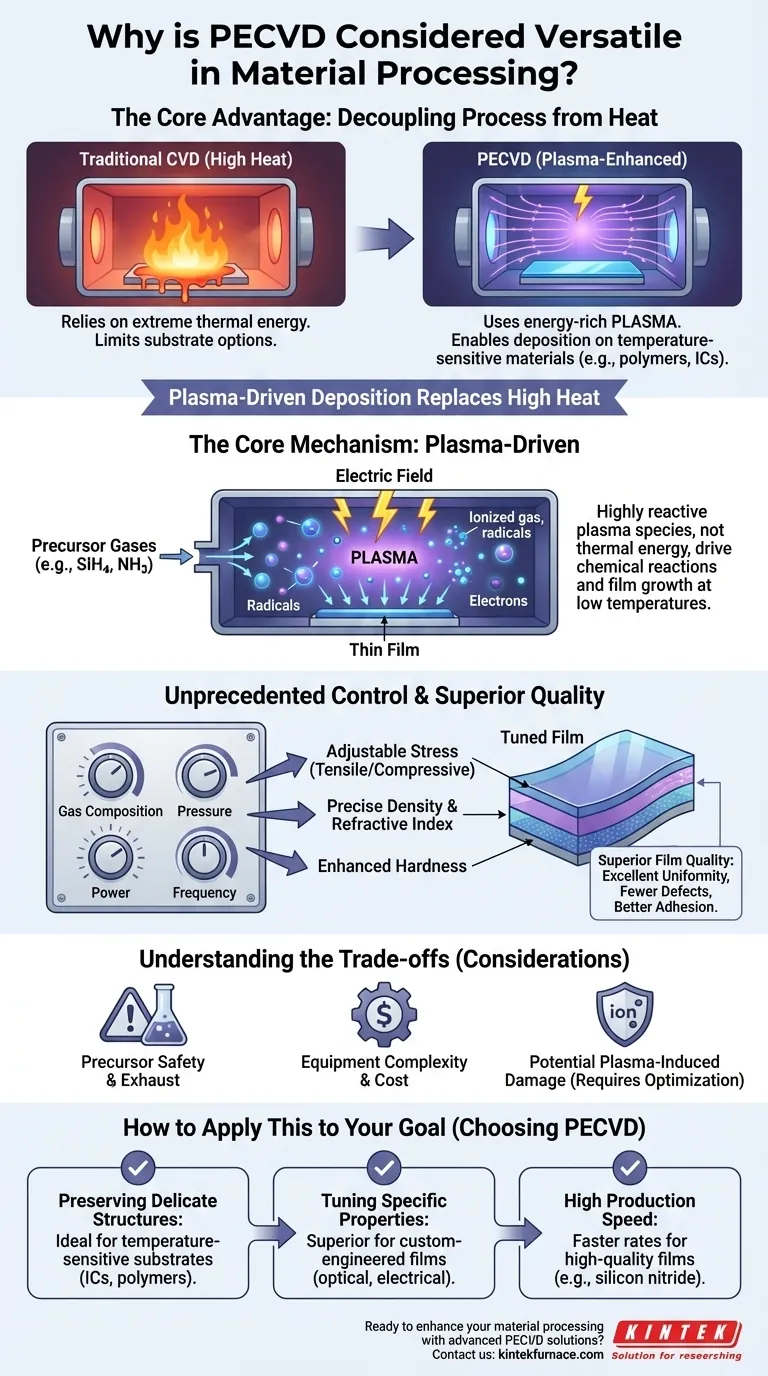

At its core, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is exceptionally versatile because it decouples the deposition process from high temperatures. By using an energy-rich plasma rather than thermal energy to initiate chemical reactions, it can deposit a vast range of high-quality thin films onto nearly any type of material, including those that are temperature-sensitive. This fundamental capability unlocks applications that are impossible with traditional high-temperature methods.

The true versatility of PECVD lies not just in the variety of materials it can create, but in its ability to do so at low temperatures. This single advantage dramatically expands the universe of compatible substrates and preserves the integrity of delicate underlying structures.

The Core Mechanism: Plasma-Driven Deposition

The power of PECVD comes from how it generates the energy needed for film growth. Unlike conventional Chemical Vapor Deposition (CVD) which relies on high heat, PECVD uses an electromagnetic field to create plasma.

How Plasma Replaces High Heat

A PECVD process takes place in a low-pressure vacuum chamber. Precursor gases, such as silane (SiH4) and ammonia (NH3), are introduced into the chamber.

An electric field is then applied, which excites electrons and collides them with neutral gas molecules. This process creates plasma—an ionized gas containing a mix of ions, radicals, and electrons.

These highly reactive plasma species, not high temperatures, provide the energy needed to break chemical bonds and drive the reactions that form a thin film on the substrate's surface.

The Advantage of Low-Temperature Operation

The ability to generate reactive species without extreme heat is the single most important factor in PECVD's versatility.

This is critical in semiconductor manufacturing, as it allows for the deposition of high-quality insulating or conductive layers on top of complex, pre-existing circuits without causing thermal stress or damage.

It also enables coating on materials with low melting points, such as polymers and plastics, opening up applications in flexible electronics, optics, and medical devices.

Unprecedented Control Over Material Properties

The use of plasma provides a level of control that thermal processes cannot match. By adjusting the plasma parameters, engineers can precisely dictate the final properties of the deposited film.

Tuning the Plasma, Tuning the Film

Operators can independently adjust variables like gas composition, pressure, and the power and frequency of the electric field.

This direct control allows for the fine-tuning of critical film characteristics such as stress, density, refractive index, and hardness. You can engineer a film to be more compressive or tensile, more or less optically dense, or harder and more scratch-resistant.

Achieving Superior Film Quality

This precise control translates directly into higher-quality films. PECVD can produce layers with excellent uniformity across the entire substrate.

The resulting films are often denser, with fewer pinhole defects and better adhesion to the substrate compared to other methods. This leads to superior performance, including high chemical and thermal stability and excellent corrosion resistance.

Understanding the Trade-offs

While powerful, PECVD is not without its considerations. Its versatility comes with inherent complexities and limitations that must be managed.

Precursor Chemistry and Safety

PECVD can process solid, liquid, or gaseous precursors, but many of these chemicals can be hazardous, toxic, or pyrophoric (igniting on contact with air). Safe handling and exhaust management are critical operational requirements.

Equipment Complexity and Cost

A PECVD system is a sophisticated piece of equipment involving a vacuum chamber, gas handling systems, and RF or microwave power supplies. This makes the initial capital investment and ongoing maintenance more significant than for some simpler deposition techniques.

Potential for Plasma-Induced Damage

The same energetic ions that enable low-temperature deposition can also, if not properly controlled, cause physical damage to the substrate surface through ion bombardment. Optimizing the process is a balancing act between achieving the desired film properties and minimizing this potential damage.

How to Apply This to Your Goal

Choosing a deposition method requires aligning the technique's strengths with your primary objective.

- If your primary focus is preserving delicate structures: PECVD is the definitive choice for depositing films on temperature-sensitive substrates like integrated circuits, polymers, or biological samples.

- If your primary focus is tuning specific film properties: The fine control over plasma parameters makes PECVD superior for creating materials with custom-engineered stress, optical, or electrical characteristics.

- If your primary focus is production speed for high-quality films: For materials like silicon nitride, PECVD offers significantly higher deposition rates than conventional CVD, improving throughput without sacrificing quality.

By leveraging plasma, PECVD provides an unparalleled combination of low-temperature processing and precise material control, making it a cornerstone technology for modern materials science.

Summary Table:

| Key Aspect | Benefit |

|---|---|

| Low-Temperature Operation | Enables deposition on temperature-sensitive materials like polymers and integrated circuits without damage |

| Precise Material Control | Allows tuning of film properties such as stress, density, and refractive index via plasma parameters |

| Wide Material Compatibility | Deposits high-quality thin films on nearly any substrate, expanding application possibilities |

| High Film Quality | Produces uniform, dense films with excellent adhesion and fewer defects for better performance |

Ready to enhance your material processing with advanced PECVD solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored high-temperature furnace systems, including our versatile PECVD systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for low-temperature, high-quality thin film deposition. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition