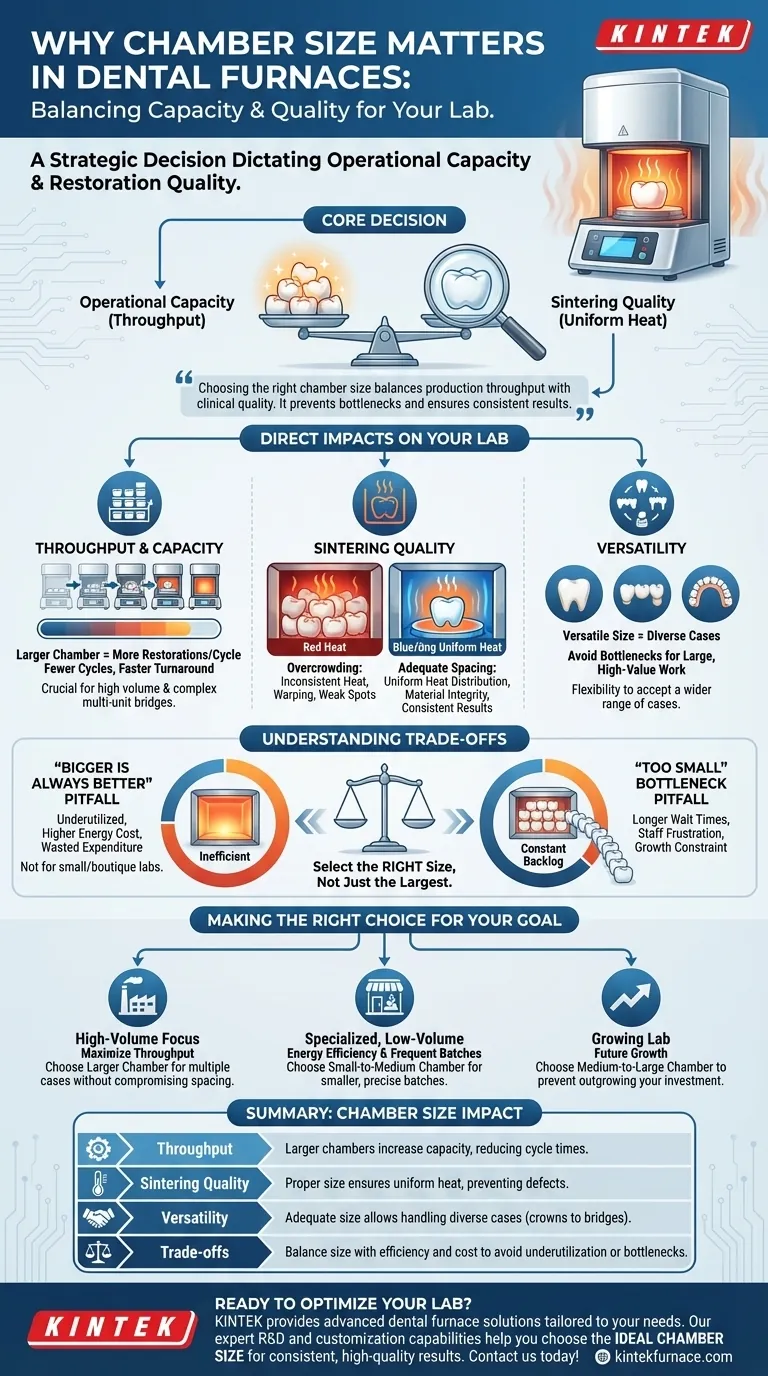

At its core, a dental furnace's chamber size is a critical decision because it directly dictates your operational capacity and the final quality of your restorations. A chamber that is properly sized for your workload allows you to process an optimal number of units efficiently, while ensuring adequate spacing for uniform heat distribution—a key factor for successful sintering and material integrity.

Choosing the right chamber size is not just about fitting restorations inside; it's a strategic decision that balances production throughput with clinical quality. The correct size optimizes your workflow, prevents production bottlenecks, and ensures consistent, predictable results for every case.

How Chamber Size Directly Impacts Your Lab

The physical dimensions of the furnace chamber have a cascading effect on your daily operations, from staff efficiency to the structural quality of the final dental prosthetic.

Throughput and Production Capacity

A larger chamber allows you to fire more restorations in a single cycle. For a high-volume lab, this means fewer cycles are needed per day, significantly improving turnaround times and overall production efficiency.

This is especially crucial when processing multiple individual cases simultaneously or handling larger, more complex restorations like multi-unit bridges.

Ensuring Consistent Sintering Quality

Proper sintering requires uniform heat. Overcrowding a small chamber prevents heat from circulating evenly around each restoration, leading to inconsistent results.

Inadequate spacing can cause warping, weak spots, or incomplete sintering, compromising the fit, strength, and aesthetics of the final product. A properly sized chamber guarantees you can maintain the manufacturer-recommended spacing for every unit.

Versatility for Diverse Cases

Your service offerings may be limited by a small chamber. While it might handle single crowns efficiently, it can become a bottleneck when a case requires a large, full-arch bridge.

A versatile chamber size gives you the flexibility to accept a wider range of cases without having to outsource or reject more complex, high-value work.

Understanding the Trade-offs

The ideal chamber size is not universal. Selecting the largest available option is a common but potentially costly mistake. A clear understanding of the trade-offs is essential.

The Pitfall of "Bigger is Always Better"

A large furnace chamber that is consistently underutilized is inefficient. It consumes more energy to heat the empty space and has a higher upfront cost.

For a smaller practice or a boutique lab focusing on a few high-value cases at a time, a massive chamber can lead to wasted operational expenditure without providing any real benefit.

The Bottleneck of "Too Small"

Conversely, choosing a chamber that is too small for your volume creates a constant production backlog. This leads to longer patient wait times, staff frustration, and an inability to scale your operations.

A small furnace can become the single biggest constraint on your lab's growth potential.

Chamber Size vs. Other Critical Features

Chamber size is a foundational feature, but it works in concert with others. A large chamber is of little use if the furnace has poor temperature control or unreliable heating elements.

Always evaluate capacity in the context of the furnace's overall technical capabilities, including ramp rates, programmability, and material compatibility.

Making the Right Choice for Your Goal

To select the right chamber size, you must first define your primary operational objective. Your decision should be a strategic investment aligned with your business model.

- If your primary focus is high-volume production: Opt for a larger chamber that can maximize throughput and accommodate multiple cases per cycle without compromising spacing.

- If your primary focus is specialized, low-volume work: A small-to-medium chamber will likely provide greater energy efficiency and may be better suited for frequent, smaller batches.

- If you are a growing lab or practice: Consider a medium-to-large chamber that provides room for future growth, preventing you from outgrowing your investment in a year or two.

Ultimately, aligning the furnace's capacity with your specific workflow transforms it from a simple piece of equipment into a strategic asset for your business.

Summary Table:

| Aspect | Impact of Chamber Size |

|---|---|

| Throughput | Larger chambers increase production capacity, reducing cycle times for high-volume labs. |

| Sintering Quality | Proper size ensures uniform heat distribution, preventing warping and weak spots in restorations. |

| Versatility | Adequate size allows handling of diverse cases, from single crowns to multi-unit bridges. |

| Trade-offs | Balance size with energy efficiency and cost to avoid underutilization or bottlenecks. |

Ready to enhance your dental lab's performance with the perfect furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements. Whether you need a furnace for high-volume output or specialized low-volume work, we'll help you choose the ideal chamber size to optimize workflow and ensure consistent, high-quality results. Contact us today to discuss your needs and discover how KINTEK can be your trusted partner in dental furnace solutions!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency