Argon is used as a protective atmosphere in induction furnaces primarily because it is a chemically inert gas. It displaces oxygen and other reactive atmospheric gases, forming a stable blanket over the molten metal that prevents oxidation, eliminates impurities, and preserves the precise chemical composition of the alloy.

The core issue isn't just preventing rust; it's about absolute process control. Choosing a protective atmosphere like argon is a deliberate engineering decision to guarantee the metallurgical purity and final properties of the cast material.

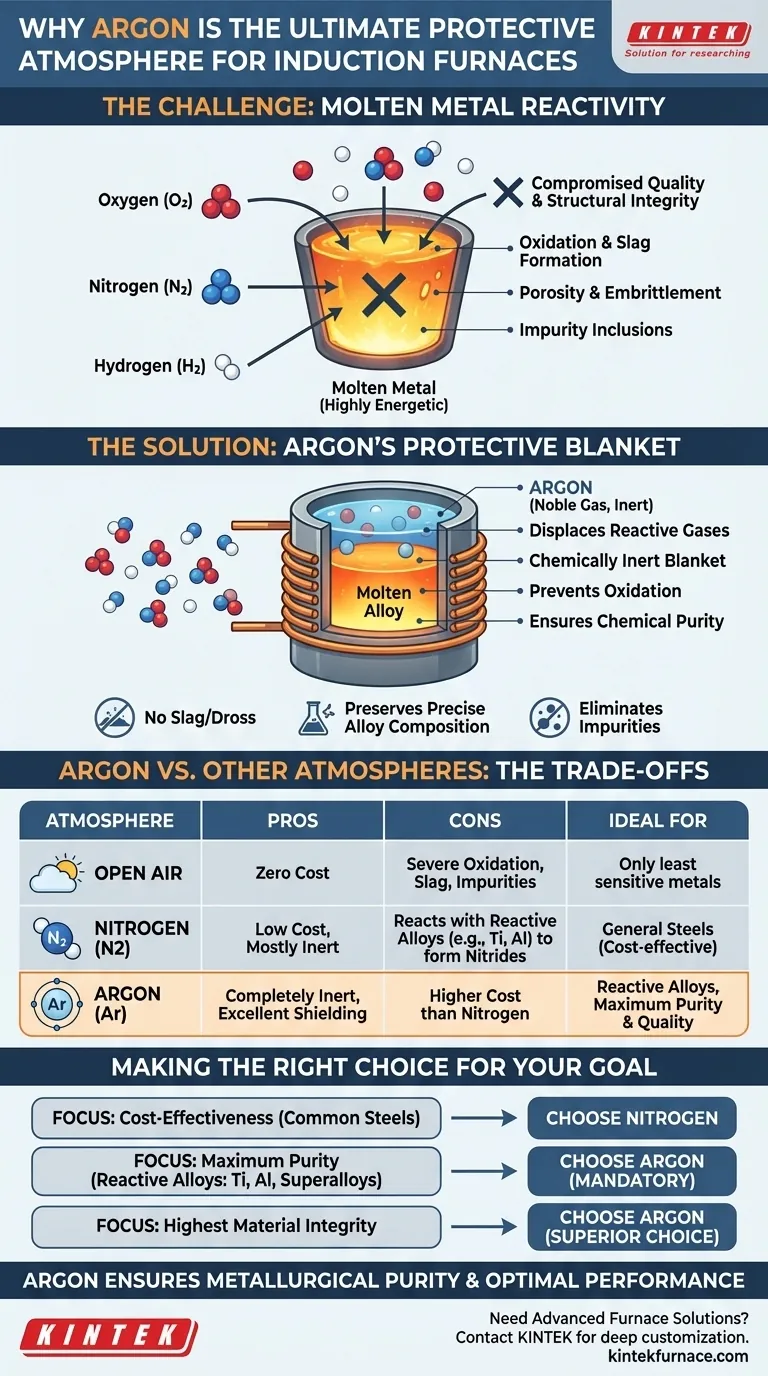

The Fundamental Challenge: A Molten Metal's Reactivity

Why Molten Metal is Vulnerable

At the high temperatures achieved in an induction furnace, metals are in a highly energetic state. Their atoms are primed to react with any available elements, particularly those in the surrounding atmosphere.

The Problem with Oxygen

The most immediate threat is oxygen. When molten metal is exposed to air, it rapidly oxidizes, forming a layer of oxides, commonly known as slag or dross.

This oxidation leads to two major problems. First, it results in a direct loss of the valuable metal itself. Second, these oxide inclusions can become trapped in the final casting, creating weak points that compromise the material's structural integrity, leading to brittleness and premature failure.

Contamination from Other Gases

Oxygen isn't the only concern. Nitrogen and hydrogen, also present in the air, can dissolve into the molten metal. This can lead to issues like porosity (gas bubbles trapped in the solid metal) and hydrogen embrittlement, which severely degrades the material's performance.

How Argon Provides a Solution

The Principle of Inertness

Argon is a noble gas, meaning its outermost electron shell is completely full. As a result, it has virtually no tendency to share electrons or form chemical bonds with other elements, even at extreme temperatures. It is, for all practical purposes, chemically non-reactive.

Displacing the Threat

By flooding the furnace chamber with argon, the lighter, reactive air (which is about 21% oxygen and 78% nitrogen) is physically displaced. Because argon is denser than air, it effectively forms a heavy, stable "blanket" directly over the surface of the melt, shielding it from contact with the atmosphere.

Ensuring Chemical Purity

Since argon does not react with the molten bath, it ensures the final alloy's chemistry remains exactly as intended. Expensive and sensitive alloying elements are not lost to oxidation, and unwanted impurities are not introduced. This guarantees the final product meets its precise metallurgical specifications.

Understanding the Trade-offs: Argon vs. Other Atmospheres

The Baseline: Open Air

Melting in an open-air atmosphere is the default but is only suitable for the least sensitive metals where significant material loss and oxide formation are acceptable. This is not a viable option for high-quality or reactive alloys.

The Competitor: Nitrogen

Nitrogen is also mostly inert and is significantly cheaper than argon, making it the most common protective atmosphere for general-purpose applications, especially for melting standard carbon and low-alloy steels.

However, nitrogen is not truly inert. At high temperatures, it can react with certain elements—most notably titanium, aluminum, and high-chromium steels—to form nitrides. These nitrides can be detrimental to the material's properties, making nitrogen unsuitable for these reactive alloys.

The Specialist: Helium

Helium is also a completely inert noble gas. However, it is much less dense than air and significantly more expensive than argon. Its low density makes it less effective at forming a stable blanket, and its high cost reserves its use for very specialized scientific or welding applications, not typically for furnace blanketing.

Making the Right Choice for Your Goal

Selecting the correct protective atmosphere is a critical decision based on the material being processed and the required quality of the final product.

- If your primary focus is cost-effectiveness for common steels: Nitrogen is almost always the most economical choice for preventing basic oxidation.

- If your primary focus is maximum purity and quality for reactive alloys: Argon is the mandatory choice to melt titanium, aluminum, nickel superalloys, or specialty stainless steels without forming unwanted nitrides.

- If your primary focus is on the highest possible material integrity: Argon provides the most absolute and reliable protection against any form of atmospheric reaction, making it the superior technical choice.

Ultimately, your choice of protective gas is a foundational decision that directly dictates the quality, performance, and reliability of your final cast product.

Summary Table:

| Aspect | Key Details |

|---|---|

| Primary Reason | Argon is chemically inert, preventing reactions with molten metals. |

| Key Benefits | Prevents oxidation, eliminates impurities, preserves alloy composition. |

| Comparison with Other Gases | More effective than nitrogen for reactive alloys; more stable and cost-effective than helium. |

| Ideal Use Cases | Essential for melting titanium, aluminum, nickel superalloys, and specialty steels. |

Need a reliable protective atmosphere solution for your induction furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, guaranteeing metallurgical purity and optimal performance for your alloys. Contact us today to discuss how we can enhance your process with tailored solutions!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process