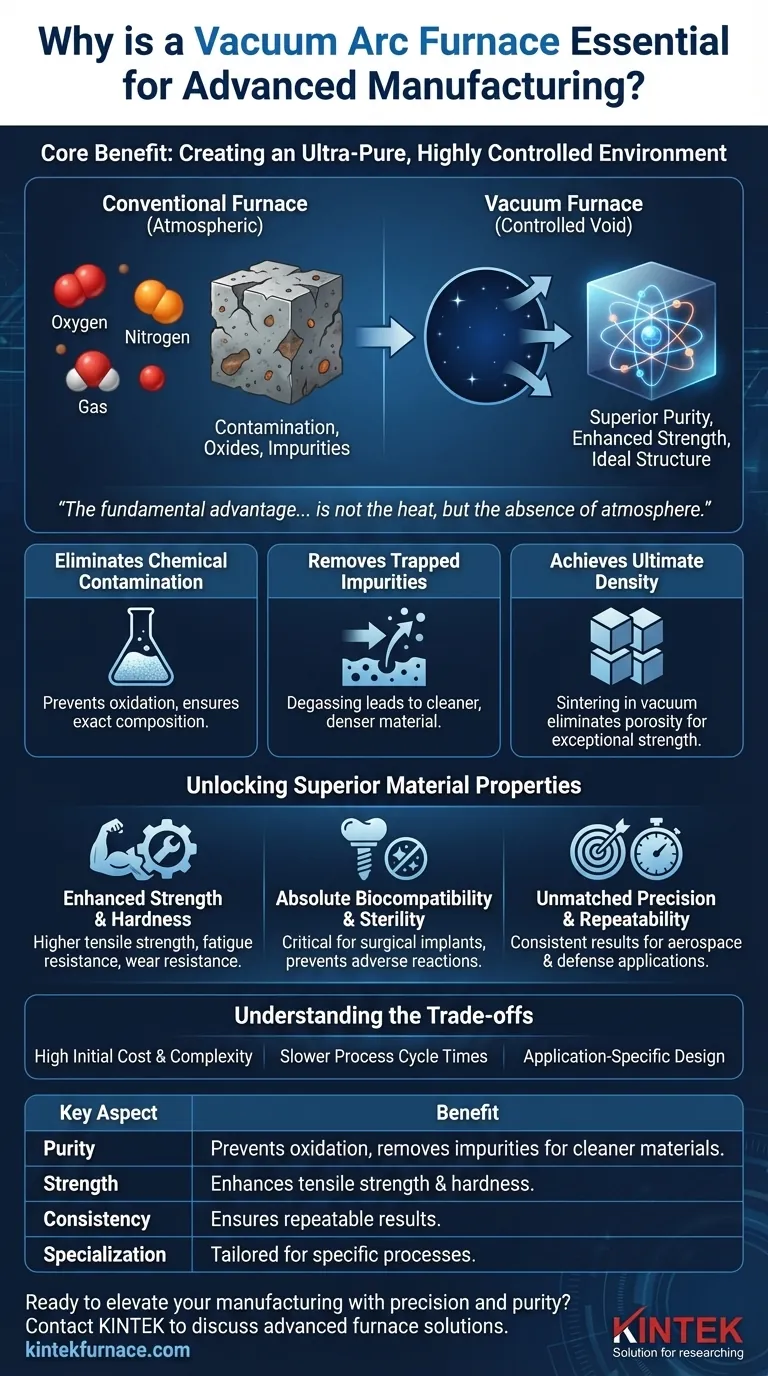

At its core, a vacuum furnace is essential for advanced manufacturing because it creates an ultra-pure, highly controlled environment that is impossible to achieve in open air. By removing atmospheric gases like oxygen and nitrogen, these furnaces prevent contamination and allow for the creation of metals, alloys, and ceramics with superior purity, strength, and specific performance characteristics that modern high-tech industries demand.

The fundamental advantage of a vacuum furnace is not the heat, but the absence of atmosphere. This controlled void allows manufacturers to eliminate impurities and manipulate material structures with a precision that unlocks properties unattainable through conventional methods.

The Principle: Why a Vacuum Changes Everything

To understand the importance of a vacuum furnace, you must first understand the problems created by a normal atmosphere during high-temperature processing. Air contains reactive gases that are detrimental to creating perfect materials.

Eliminating Chemical Contamination

At high temperatures, materials become highly reactive. In a conventional furnace, metals will readily react with oxygen in the air to form oxides, which are brittle impurities that compromise the material's integrity.

A vacuum removes these reactive gases. This creates a chemically clean slate, preventing unwanted reactions like oxidation and ensuring the final material's composition is exactly what was intended.

Removing Trapped Impurities

Many materials, especially metals, contain dissolved gases like hydrogen and volatile elements from their initial production. In a vacuum, the pressure difference literally pulls these impurities out of the molten or heated material.

This degassing process results in a cleaner, more refined, and less porous material, directly contributing to superior mechanical properties.

Achieving Ultimate Density

For materials like advanced ceramics or powdered metals, the goal is to fuse particles together into a solid, dense mass through a process called sintering. Air trapped between particles can prevent them from fully bonding, creating microscopic voids (porosity).

Porosity acts as a stress point and a pathway for cracks, severely weakening the material. By performing this process in a vacuum, trapped gases are eliminated, allowing the material to achieve near-theoretical density and exceptional strength.

The Result: Unlocking Superior Material Properties

By controlling the environment at a fundamental level, vacuum furnaces enable the production of materials with tangible, mission-critical advantages.

Enhanced Strength and Hardness

The removal of impurities and the reduction of porosity lead directly to materials with higher tensile strength, improved fatigue resistance, and greater hardness.

Processes like vacuum quenching (rapid cooling) for tool steels can be performed without surface decarburization, resulting in tools that are harder and more wear-resistant from the surface to the core.

Absolute Biocompatibility and Sterility

In the medical field, material failure is not an option. Vacuum melting is used to produce surgical implants and components for robotic surgery.

The extreme purity achieved in a vacuum is critical for ensuring biocompatibility, preventing adverse reactions with the human body, and guaranteeing the material's sterility and precise chemical makeup.

Unmatched Precision and Repeatability

Advanced manufacturing is built on consistency. A vacuum is a highly stable and predictable environment, free from the fluctuations of atmospheric composition or humidity.

This allows for automated processes with unmatched precision and repeatability, ensuring that a specialized alloy or ceramic produced today has the exact same properties as one produced a year from now. This is vital for aerospace, defense, and semiconductor applications.

Understanding the Trade-offs

While indispensable, vacuum furnace technology is not a universal solution and comes with clear trade-offs.

High Initial Cost and Complexity

Vacuum furnaces are a significant capital investment. They require complex pumping systems, robust chamber engineering, and precise controls, making them more expensive to purchase and install than conventional atmospheric furnaces.

Slower Process Cycle Times

Achieving a deep vacuum and executing a controlled heating and cooling profile takes time. The process of pumping down the chamber, processing, and backfilling means cycle times are typically longer than for atmospheric processes. This is the trade-off for unparalleled quality.

Application-Specific Design

There is no single "vacuum furnace." A vacuum arc remelting (VAR) furnace for titanium alloys, a vacuum sintering furnace for ceramics, and a vacuum hot press for composites are all highly specialized pieces of equipment designed for different materials and outcomes.

How to Apply This to Your Goal

The decision to use a vacuum furnace hinges entirely on whether the end-product's performance requirements justify the investment in environmental control.

- If your primary focus is peak performance and reliability: For aerospace, defense, or motorsport applications, the enhanced strength and purity from vacuum processing are non-negotiable for safety and performance.

- If your primary focus is ultimate density and thermal resistance: For advanced ceramics in automotive or electronics, vacuum sintering is the only way to eliminate the porosity that cripples strength and thermal management.

- If your primary focus is absolute purity and safety: For medical implants or high-purity materials for scientific research, the sterile and non-reactive vacuum environment is essential for ensuring biocompatibility and compositional integrity.

Ultimately, a vacuum furnace is the tool that enables manufacturers to move beyond the limitations of nature and engineer materials at the atomic level.

Summary Table:

| Key Aspect | Benefit |

|---|---|

| Purity | Prevents oxidation and removes impurities for cleaner materials |

| Strength | Enhances tensile strength and hardness through degassing and sintering |

| Consistency | Ensures repeatable results in aerospace, medical, and semiconductor fields |

| Specialization | Tailored for processes like vacuum arc remelting and sintering |

Ready to elevate your manufacturing with precision and purity? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our vacuum furnaces can deliver superior performance for your specific needs in aerospace, medical, or other high-tech sectors!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications