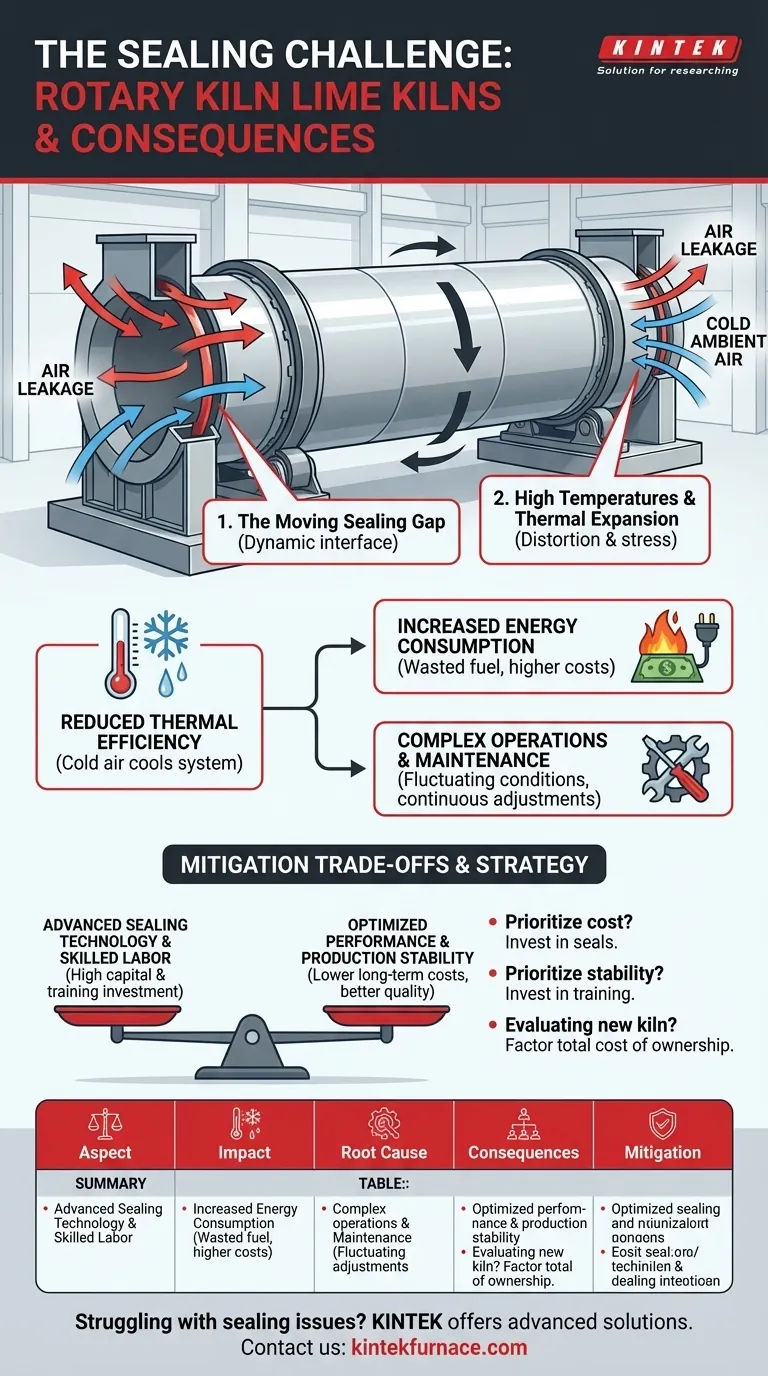

The fundamental sealing challenge of a rotary kiln lime kiln originates from its core design: it is a massive, rotating cylinder operating at extreme temperatures. Sealing the gap between this moving kiln body and the stationary inlet and outlet hoods is an inherent engineering difficulty. This imperfect seal leads to significant air leakage, which directly reduces thermal efficiency and dramatically increases fuel consumption.

Poor sealing in a rotary kiln is not a simple maintenance flaw but an inherent design challenge. The resulting air leakage creates a domino effect, driving up energy costs, complicating operations, and demanding significant investment in either advanced sealing technology or highly skilled personnel to mitigate the losses.

The Root Cause: An Inherent Design Challenge

The difficulty in sealing a rotary kiln is not a sign of poor manufacturing but a consequence of its operational physics. Two main factors are at play.

The Moving Sealing Gap

A rotary kiln is in constant motion, rotating to process material. This creates a dynamic gap between the end of the kiln shell and the stationary hoods where material enters and exits. Creating a durable, airtight seal on this massive, moving, and abrasive interface is exceptionally difficult.

High Temperatures and Thermal Expansion

The kiln operates at very high temperatures, causing the steel shell to expand and contract. This thermal movement, combined with the kiln's own weight and mechanical stresses, causes slight distortions in the circular shape of the shell, making a perfect, consistent seal nearly impossible to maintain.

The Cascade of Consequences

An inadequate seal is not a minor issue; it triggers a series of operational and financial problems that directly impact the plant's bottom line and stability.

Reduced Thermal Efficiency

The primary consequence of air leakage is a loss of thermal efficiency. Cold ambient air is drawn into the kiln system, while hot process gas escapes. This ingress of cold air cools the internal environment, forcing the system to burn more fuel to maintain the required calcination temperature.

Increased Energy Consumption

Directly tied to poor thermal efficiency, increased energy consumption is the most significant financial drain. Every cubic foot of air that leaks into the kiln must be heated, representing wasted fuel and a direct increase in operational cost.

Complex Operations and Maintenance

The constant battle against leaks makes operating and maintaining the kiln more complex. It necessitates a higher level of operator skill to manage fluctuating temperatures and process conditions. Maintenance becomes a continuous effort to adjust or replace sealing components.

Understanding the Mitigation Trade-offs

Addressing poor sealing performance is not a simple fix; it involves significant strategic and financial trade-offs. The solutions themselves introduce new costs and complexities.

The Cost of Upgrades

To effectively reduce air leakage, facilities must invest in advanced sealing systems. While these technologies can significantly improve efficiency, they represent a substantial capital expenditure. Furthermore, their installation requires production downtime, extending renovation cycles and creating opportunity costs.

The Demand for Skilled Labor

A rotary kiln is a complex piece of machinery that demands skilled operators and maintenance staff. Improper operation or delayed maintenance, especially concerning the seals, can quickly lead to equipment failures or production accidents. This requires a continuous investment in technical training and robust maintenance management.

The Risk of Production Instability

Failing to properly manage kiln sealing can lead to unstable production. Fluctuating internal temperatures can affect the quality and consistency of the final lime product. In severe cases, equipment failures resulting from poor maintenance can cause unplanned shutdowns and significant production losses.

Making an Informed Decision for Your Facility

Your approach to managing kiln sealing must align with your primary operational goals. There is no single solution, only a balanced strategy tailored to your facility's needs.

- If your primary focus is minimizing operational costs: Prioritize investment in advanced sealing technology and a proactive maintenance schedule to directly combat energy loss from air leakage.

- If your primary focus is maximizing operational stability and safety: Invest heavily in operator training and establish rigorous maintenance protocols, as human error and neglect are major contributors to equipment failure.

- If you are evaluating new kiln technology: Scrutinize the proposed sealing system and factor the long-term costs of maintenance, energy consumption, and specialized labor into your total cost of ownership analysis.

By understanding that kiln sealing is a strategic balance of equipment, cost, and skill, you can better control your production environment and achieve your operational goals.

Summary Table:

| Aspect | Impact |

|---|---|

| Root Cause | Inherent design challenge with moving gaps and thermal expansion |

| Consequences | Reduced thermal efficiency, increased energy consumption, complex operations |

| Mitigation | Advanced sealing technology, skilled labor investment, proactive maintenance |

Struggling with sealing issues in your rotary kiln? KINTEK specializes in advanced high-temperature furnace solutions, including custom rotary furnaces designed to enhance sealing and efficiency. With our exceptional R&D and in-house manufacturing, we provide deep customization to meet your unique needs, reducing energy costs and improving operational stability. Contact us today to discuss how we can optimize your kiln performance!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are some common processes carried out in rotary kilns? Unlock Efficient Material Transformation Solutions

- What distinguishes direct from indirect rotary kilns? Choose the Right Kiln for Your Material

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What supporting equipment is needed for a rotary kiln system? Essential Components for Efficient Thermal Processing

- What role does gas flow and combustion play in a rotary kiln? Optimize Heat Transfer for Efficiency and Quality