In short, PECVD provides excellent substrate adhesion because it uses plasma to actively prepare the substrate surface for bonding. Unlike other methods that may require a separate pre-treatment step, PECVD performs an in-situ cleaning and activation of the surface, creating a highly receptive foundation for the film to grow on. This process removes contaminants and creates reactive chemical sites, which are critical for forming a strong, durable interface.

The key to PECVD's superior adhesion lies in its dual function. The same plasma that drives the chemical vapor deposition also serves as a powerful surface treatment tool, cleaning and energizing the substrate to ensure the strongest possible chemical and physical bonds from the very first atomic layer.

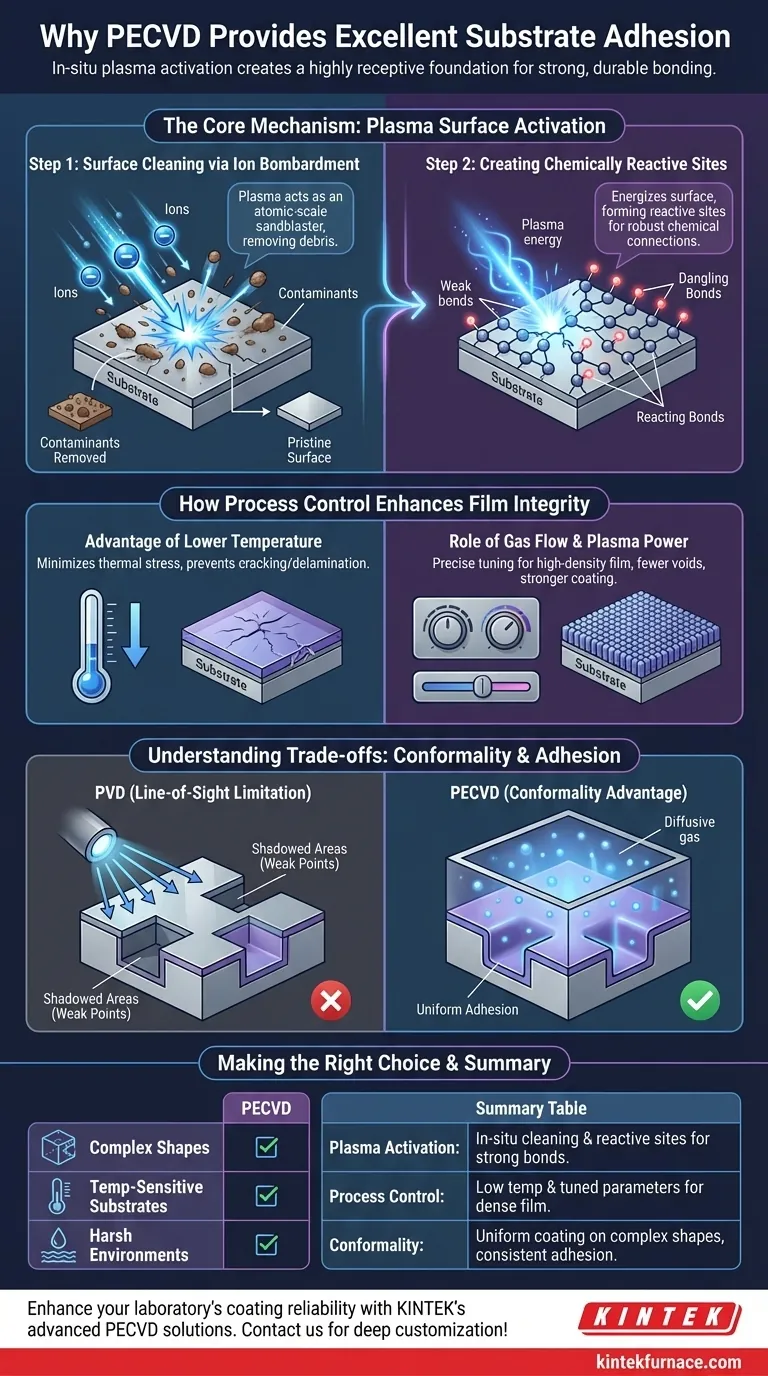

The Core Mechanism: Plasma Surface Activation

The term "plasma activation" is central to understanding PECVD's adhesion capabilities. This isn't a passive effect; it's an active, physical, and chemical modification of the substrate that happens just before and during the initial moments of deposition.

Step 1: Surface Cleaning via Ion Bombardment

Before the film-forming chemistry begins, the ions within the plasma act like an atomic-scale sandblaster.

These energetic ions strike the substrate, physically sputtering away microscopic contaminants like organic residues or native oxides. This process ensures the film is deposited onto a pristine surface, not on a weak layer of debris.

Step 2: Creating Chemically Reactive Sites

The plasma doesn't just clean the surface; it energizes it by breaking weak chemical bonds on the substrate itself.

This creates "dangling bonds"—highly reactive atomic sites that are eager to form new, strong chemical connections. When the film precursor molecules arrive, they bond directly to these activated sites, forming a robust covalent interface rather than just weakly adhering to the surface.

How Process Control Enhances Film Integrity

Excellent adhesion is also a result of the high-quality film that PECVD produces. Precise control over the process parameters is crucial for building a dense, stable film that won't fail internally.

The Advantage of Lower Temperature

A key benefit of PECVD is its relatively low operating temperature compared to conventional CVD.

This minimizes thermal stress between the film and the substrate, which is especially important when their coefficients of thermal expansion differ. Reduced stress means a lower risk of cracking or delamination during cooling or thermal cycling.

The Role of Gas Flow and Plasma Power

Process parameters like gas flow rate and plasma power are carefully tuned to control the reaction.

This ensures that the film-forming species have the right energy and density, promoting high surface mobility. This allows atoms to settle into a dense, well-ordered film structure with fewer voids, leading to a mechanically stronger coating that adheres more tenaciously.

Understanding the Trade-offs: Conformality and Adhesion

For any real-world application, especially those with complex geometries, how well a coating covers the surface is just as important as how well it sticks. This is where PECVD has a distinct advantage over line-of-sight methods.

The "Line-of-Sight" Limitation of PVD

Physical Vapor Deposition (PVD) techniques, such as sputtering or evaporation, are considered "line-of-sight." The coating material travels in a straight line from the source to the substrate.

This means that complex features like trenches, steps, or even microscopic roughness can create "shadows" where the coating is much thinner or non-existent. These shadowed areas become points of mechanical weakness and poor adhesion.

The Conformality Advantage of PECVD

PECVD, by contrast, is a diffusive, gas-driven process. The reactive gas precursors surround the substrate, and the plasma fills the entire chamber.

This allows the deposition to occur on all surfaces simultaneously, regardless of their orientation to the source. The resulting film is highly conformal, maintaining uniform thickness and, consequently, uniform adhesion even on the most complex and uneven surfaces.

Making the Right Choice for Your Application

The decision to use PECVD is often driven by the need for robust film performance under challenging conditions. Your specific goal will determine how valuable its adhesion properties are.

- If your primary focus is durability on complex shapes: PECVD is the superior choice due to its high conformality, which ensures consistent adhesion in trenches and on curved surfaces.

- If your primary focus is coating temperature-sensitive substrates: PECVD is often the only viable option, as its lower process temperature prevents substrate damage while still delivering excellent adhesion.

- If your primary focus is maximum reliability in harsh environments: PECVD's in-situ plasma cleaning provides an inherent process advantage, reducing the risk of adhesion failure due to surface contamination.

Ultimately, selecting PECVD is a decision to prioritize the fundamental integrity of the film-substrate interface.

Summary Table:

| Aspect | Key Details |

|---|---|

| Plasma Activation | In-situ cleaning via ion bombardment and creation of reactive sites for strong chemical bonds. |

| Process Control | Low temperature minimizes thermal stress; tuned gas flow and plasma power enhance film density. |

| Conformality | Diffusive process ensures uniform coating on complex shapes, improving adhesion in all areas. |

| Applications | Ideal for temperature-sensitive substrates, harsh environments, and complex geometries. |

Enhance your laboratory's coating reliability with KINTEK's advanced PECVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems, including CVD/PECVD Systems, tailored to your unique experimental needs. Our strong deep customization capability ensures precise adhesion performance for durable films. Contact us today to discuss how our solutions can benefit your projects!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition