At its core, the broad applicability of a tube furnace stems from its unique ability to provide exceptionally precise control over both temperature and atmosphere within a contained environment. This combination of high-purity heating and environmental regulation makes it an indispensable tool for a vast range of advanced material synthesis and processing applications, from semiconductors to nanomaterials.

The fundamental advantage of a tube furnace lies in its cylindrical design. This simple geometry is inherently superior for creating a uniform temperature profile and for isolating a sample in a tightly controlled vacuum or specific gas atmosphere, a requirement that cuts across countless scientific and industrial fields.

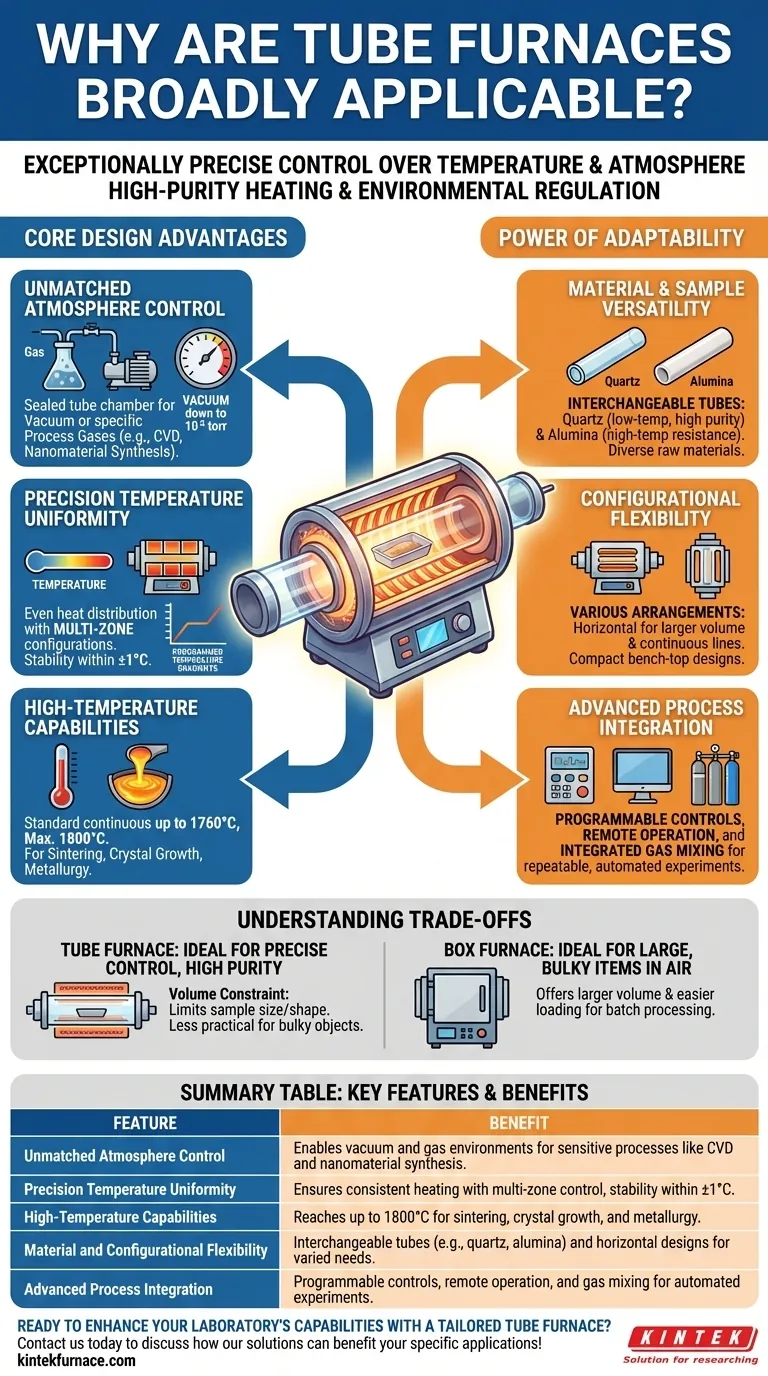

The Core Design Advantages

A tube furnace's versatility is not a single feature, but the result of several integrated design principles that work in concert.

Unmatched Atmosphere Control

The defining feature of a tube furnace is its sealed tube chamber. This design allows for the direct introduction of process gases or the application of a vacuum.

This makes it ideal for processes that are sensitive to oxygen or require a specific reactive environment. Applications like chemical vapor deposition (CVD), nanomaterial synthesis, and semiconductor doping rely on this precise control, which can achieve vacuum conditions down to 10⁻⁵ torr.

Precision Temperature Uniformity

The cylindrical heating chamber naturally promotes even heat distribution around the sample. This uniformity is critical for consistent material properties.

Modern furnaces enhance this with multi-zone configurations, where different sections of the tube can be controlled independently. This allows for programmed temperature gradients and achieves exceptional stability, often within ±1°C of the setpoint.

High-Temperature Capabilities

Tube furnaces are engineered to reach extreme temperatures required for creating advanced materials.

Standard models operate continuously up to 1760°C, with maximum temperatures reaching 1800°C. This capability is essential for sintering advanced ceramics, growing crystals, and conducting metallurgical research.

The Power of Adaptability

Beyond its core heating and atmosphere functions, the tube furnace's design allows it to be configured for a wide array of specific tasks.

Material and Sample Versatility

The process tube itself is interchangeable. Quartz tubes are used for lower-temperature processes where high purity and visual monitoring are key, while alumina tubes are used for high-temperature applications demanding excellent thermal and chemical resistance.

This adaptability, combined with advancements in processing technology, allows a single furnace to handle a diverse range of raw materials and sample types.

Configurational Flexibility

Tube furnaces come in various physical arrangements to suit different needs. Horizontal furnaces, for instance, offer a larger effective working volume, making them suitable for processing bigger samples or for continuous production lines.

Their compact, bench-top footprint makes them easy to integrate into a lab environment, while more complex systems can be built for industrial-scale work.

Advanced Process Integration

Modern tube furnaces are more than just heaters; they are sophisticated processing systems. Fully programmable control panels allow for complex, multi-step temperature cycles.

Furthermore, software compatibility enables remote operation and data logging, while integrated gas mixing systems can deliver precise gas compositions to the chamber, allowing for highly repeatable and automated experiments.

Understanding the Trade-offs

While highly versatile, the tube furnace is not the universal solution for all heating applications. Its primary limitation is its geometry.

The Volume Constraint

The cylindrical chamber, while excellent for atmosphere control, inherently limits the size and shape of the sample. Processing very large, bulky, or irregularly shaped objects is often impractical.

In these scenarios, a box furnace is a better alternative. Box furnaces offer a much larger, more accessible chamber, designed for heat-treating large parts or firing many smaller items simultaneously in an air atmosphere.

Sample Loading and Access

Loading and unloading a long, narrow tube can be more cumbersome than placing an item on the hearth of a front-loading box furnace. This is a practical consideration for high-throughput batch processes where speed and ease of handling are critical.

Making the Right Choice for Your Process

Selecting the correct furnace requires matching the tool's strengths to your primary objective.

- If your primary focus is precise atmosphere control or high purity: A tube furnace is the definitive choice for its sealed environment.

- If your primary focus is processing large, bulky, or numerous individual items in air: A box furnace offers superior volume and accessibility.

- If your primary focus is high-temperature synthesis with maximum thermal uniformity: A multi-zone tube furnace provides unparalleled temperature stability and control.

- If your primary focus is flexibility for varied research projects: The interchangeable tubes and configurable nature of a tube furnace make it a highly adaptable lab instrument.

Ultimately, choosing the right furnace is about selecting the tool that gives you the most precise control over the conditions your material requires.

Summary Table:

| Feature | Benefit |

|---|---|

| Unmatched Atmosphere Control | Enables vacuum and gas environments for sensitive processes like CVD and nanomaterial synthesis |

| Precision Temperature Uniformity | Ensures consistent heating with multi-zone control, stability within ±1°C |

| High-Temperature Capabilities | Reaches up to 1800°C for sintering, crystal growth, and metallurgy |

| Material and Configurational Flexibility | Interchangeable tubes (e.g., quartz, alumina) and horizontal designs for varied needs |

| Advanced Process Integration | Programmable controls, remote operation, and gas mixing for automated experiments |

Ready to enhance your laboratory's capabilities with a tailored tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization to precisely meet your unique experimental requirements. Whether you're in semiconductors, nanomaterials, or other advanced fields, we can help you achieve superior results. Contact us today to discuss how our solutions can benefit your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab