In material science, muffle furnaces are essential because they provide a highly controlled and contaminant-free environment for high-temperature processing. This precision allows researchers and engineers to predictably alter or analyze the properties of materials, enabling everything from fundamental research to industrial quality control.

The true value of a muffle furnace isn't just its ability to get hot, but its ability to isolate a material from the heating source itself. This "muffle" creates a pristine chamber, ensuring that any changes to the material are a direct result of temperature and atmosphere, not contamination.

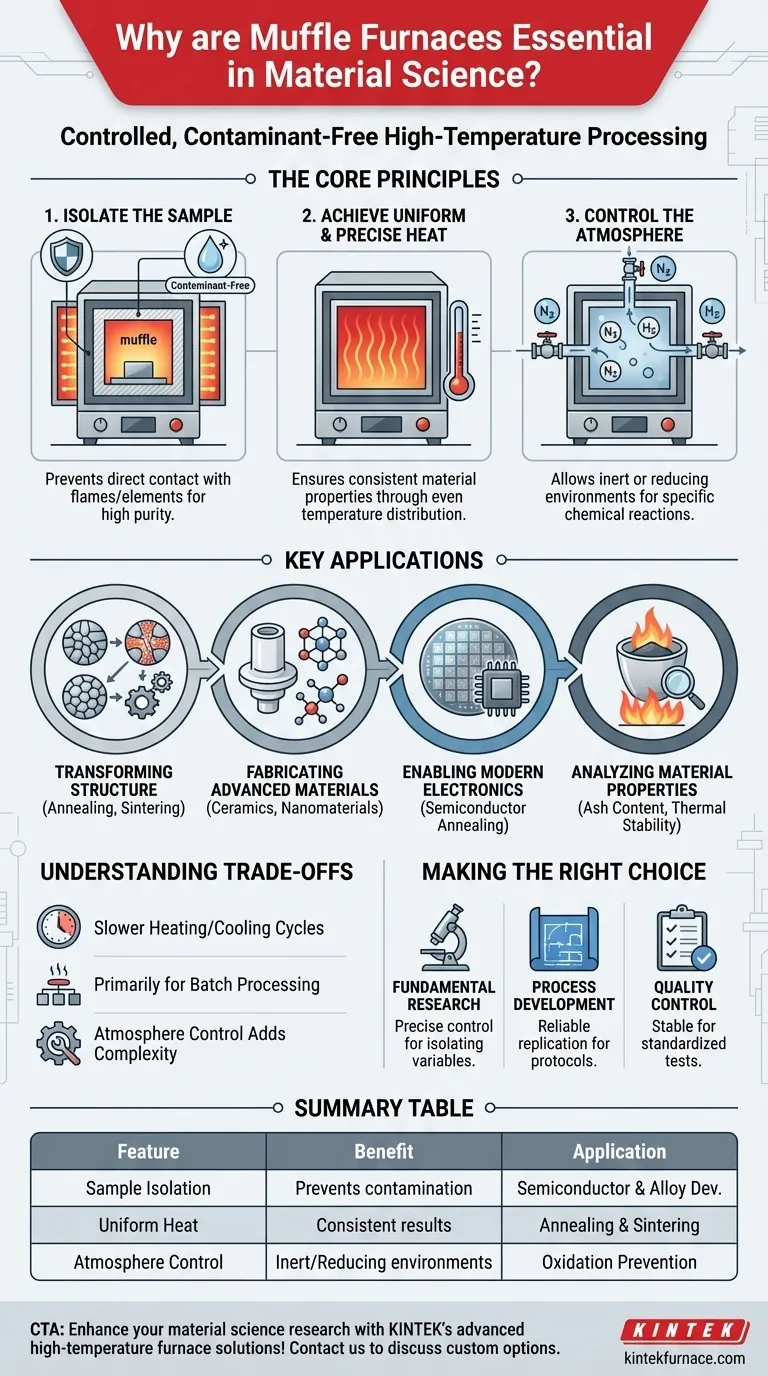

The Core Principles of a Muffle Furnace

To understand why this tool is indispensable, we must look at the three principles that define its function. These capabilities work in concert to give scientists precise control over material transformation.

Principle 1: Isolate the Sample

A muffle furnace contains an inner chamber—the "muffle"—that is heated from the outside by heating elements.

The sample inside never comes into direct contact with flames or the electrical elements. This isolation is critical for preventing contamination, which is vital for high-purity applications like semiconductor and advanced alloy development.

Principle 2: Achieve Uniform and Precise Heat

These furnaces are designed for exceptional temperature stability and uniformity, often using a combination of radiative and convective heat transfer.

This ensures that the entire sample experiences the same temperature, which is crucial for processes like annealing, where even minor temperature variations can lead to inconsistent material properties.

Principle 3: Control the Atmosphere

Many advanced models allow for the introduction of specific gases, creating a controlled atmosphere within the muffle.

Researchers can create an inert environment with nitrogen to prevent oxidation of sensitive metals or a reducing atmosphere with hydrogen to remove oxygen from a material. This atmospheric control dramatically expands the range of possible chemical and physical transformations.

Key Applications in Material Science

The combination of isolation, precision heat, and atmospheric control makes the muffle furnace a workhorse for a wide range of critical tasks.

Transforming Material Structure

Processes like annealing and sintering are foundational to materials engineering. Annealing heats and slowly cools a metal to increase its ductility and reduce hardness.

Sintering uses heat to fuse powders into a solid, cohesive mass without melting them, a key step in producing ceramics and certain metal parts.

Fabricating Advanced Materials

Muffle furnaces are used for firing and co-firing technical ceramics to create durable, high-performance components used in aerospace and electronics.

They are also indispensable for researching and developing new nanomaterials, composites, and alloys where precise thermal processing is required to achieve desired properties.

Enabling Modern Electronics

In semiconductor manufacturing, muffle furnaces perform critical annealing treatments. For example, processing silicon wafers at temperatures around 1000°C in a controlled atmosphere optimizes their crystal structure and conductivity.

This step is essential for enhancing the electrical properties of the materials that power our electronic devices.

Analyzing Material Properties

In a laboratory setting, muffle furnaces are used for analytical tests. This includes ash content determination, where a sample is burned completely to measure its inorganic residue.

They are also used for testing the thermal degradation and stability of polymers and plastics, providing crucial data for quality control and product safety.

Understanding the Trade-offs

While incredibly useful, the muffle furnace is not the right tool for every thermal task. Understanding its limitations is key to using it effectively.

Slower Heating and Cooling Cycles

The heavy insulation that gives a muffle furnace its temperature stability also means it heats up and cools down relatively slowly. For applications requiring rapid thermal cycling, other methods like induction heating may be more suitable.

Primarily for Batch Processing

Most muffle furnaces are designed for lab-scale or small batch work. Their nature does not lend itself to the continuous, high-volume processing found in large-scale industrial manufacturing.

Atmosphere Control Adds Complexity

While atmospheric control is a powerful feature, it adds significant complexity and cost. Achieving a true high-vacuum or ensuring a perfectly pure inert atmosphere requires specialized equipment and careful operation.

Making the Right Choice for Your Goal

The value of a muffle furnace lies in its ability to provide a repeatable and pure thermal environment. How you leverage it depends entirely on your objective.

- If your primary focus is fundamental research: A furnace with precise temperature and atmosphere control is essential for isolating variables and studying material behavior under specific conditions.

- If your primary focus is process development: The furnace's ability to reliably replicate conditions for annealing, sintering, or brazing is critical for creating consistent manufacturing protocols.

- If your primary focus is quality control: The furnace's stability makes it the ideal tool for standardized tests like ash content analysis, ensuring products meet required specifications.

Ultimately, the muffle furnace serves as a fundamental bridge between a material's composition and its final, functional properties.

Summary Table:

| Feature | Benefit | Application |

|---|---|---|

| Sample Isolation | Prevents contamination for high-purity results | Semiconductor and alloy development |

| Uniform Heat | Ensures consistent temperature for reliable outcomes | Annealing and sintering processes |

| Atmosphere Control | Allows inert or reducing environments for specific reactions | Oxidation prevention and material transformation |

Enhance your material science research with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precise, customizable options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for contaminant-free, reliable thermal processing. Contact us today to discuss how our solutions can optimize your lab's efficiency and results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites