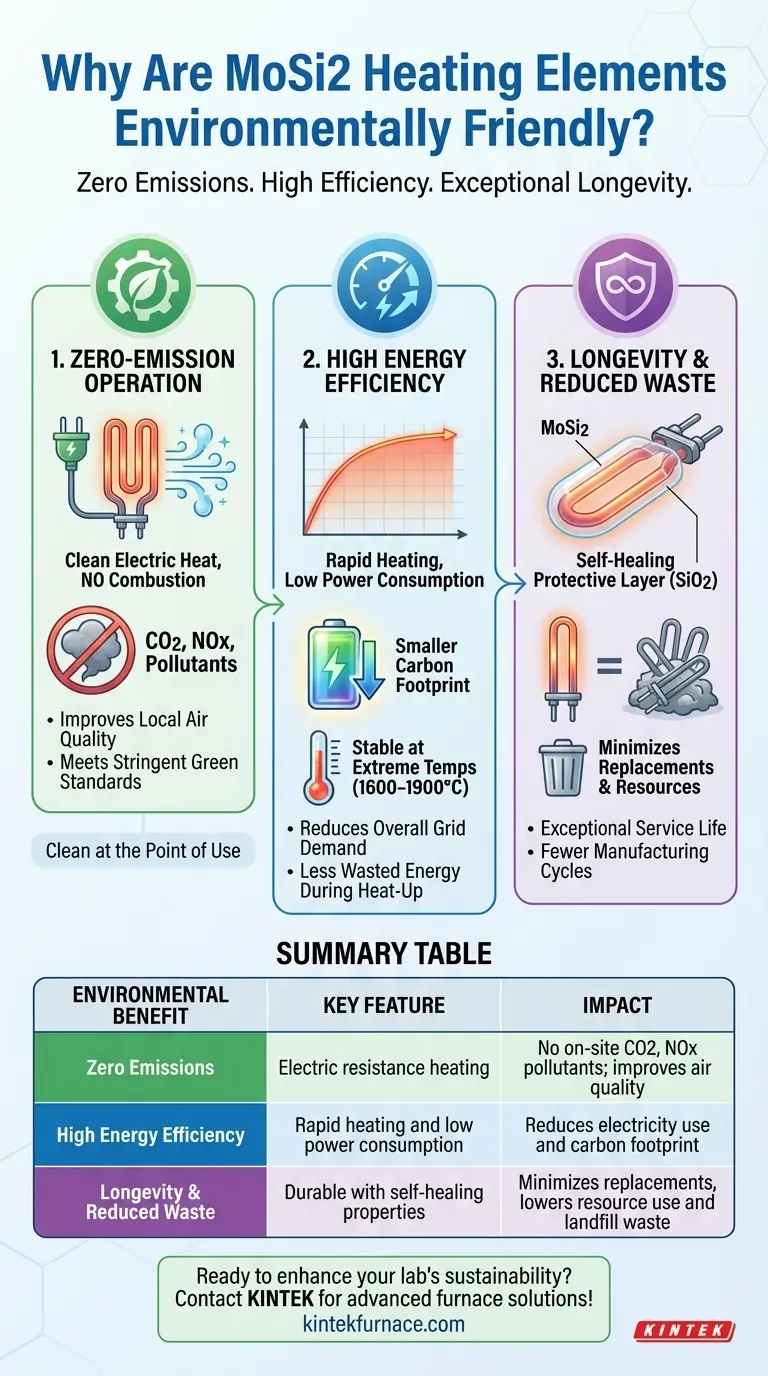

At their core, Molybdenum Disilicide (MoSi₂) heating elements are considered environmentally friendly because they produce zero harmful emissions during operation and are highly energy-efficient. Unlike combustion-based heating methods that burn fossil fuels, these electric elements generate heat cleanly, directly contributing to better air quality and compliance with environmental standards.

The environmental benefit of MoSi₂ elements extends beyond just clean operation. Their true value lies in a combination of high energy efficiency, which reduces overall power consumption, and exceptional longevity, which minimizes waste and the resources needed for replacements.

The Foundation: Zero-Emission Operation

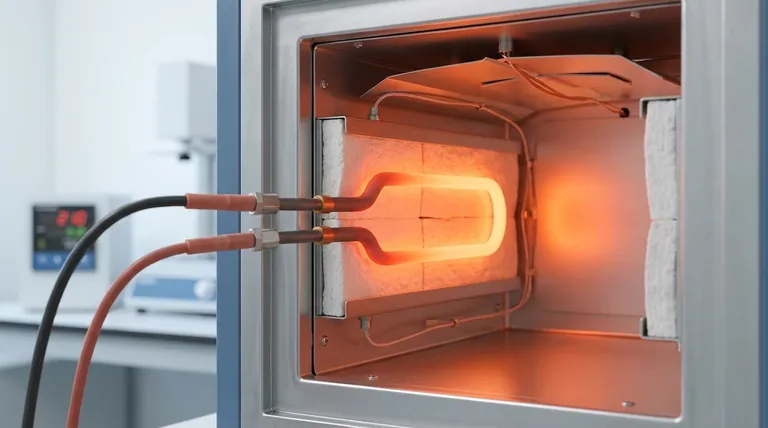

The most immediate environmental advantage of MoSi₂ heating elements comes from how they generate heat. They are a form of electric resistance heating, a fundamentally clean process.

Clean Heat, No Combustion

MoSi₂ elements work by passing electricity through a material with high resistance, generating heat without any chemical reaction or burning of fuel. This means they produce zero on-site emissions of carbon dioxide (CO₂), nitrogen oxides (NOx), or other pollutants associated with natural gas or oil furnaces.

This makes them an ideal choice for applications where air quality is a critical concern, both for employee health and for preventing contamination of the products being heated.

Meeting Green Standards

Because they eliminate local emissions, furnaces using MoSi₂ elements easily meet and exceed stringent environmental protection standards. This operational cleanliness is a key reason they are specified in modern industrial and laboratory settings.

Efficiency and Its Environmental Impact

Beyond being clean at the point of use, the efficiency of MoSi₂ elements plays a significant role in their positive environmental profile.

High Heating Rate and Low Power Consumption

These elements are known for their ability to convert electricity into heat with very high efficiency and to reach target temperatures rapidly. This performance means less energy is wasted during heat-up cycles and operation.

Lower power consumption directly translates to a smaller carbon footprint, as it reduces the overall demand on the electrical grid.

Stability at Extreme Temperatures

MoSi₂ elements can operate stably at exceptionally high temperatures, often between 1600°C and 1900°C. This allows for industrial processes like ceramics sintering and glass production to be conducted with greater precision and efficiency, minimizing wasted material and energy.

The Hidden Benefit: Longevity and Reduced Waste

An often-overlooked aspect of sustainability is the lifespan of a component. The durability of MoSi₂ elements is a major contributor to their eco-friendly status.

Exceptional Service Life

MoSi₂ elements are engineered for durability and have a very long service life, even in continuous high-temperature, oxidizing atmospheres. They are resistant to thermal shock and maintain their integrity over thousands of hours.

Minimizing Resource Consumption

A longer lifespan means fewer replacements are needed over the life of a furnace. This reduces the environmental impact associated with manufacturing new elements, including raw material extraction, energy consumption during production, and transportation. It also means less scrap material ends up in landfills.

The Self-Healing Advantage

At high temperatures in the presence of oxygen, MoSi₂ elements form a protective, passive layer of quartz glass (SiO₂) on their surface. This layer prevents further oxidation and effectively "heals" the element, which is a key mechanism behind its remarkable durability.

Understanding the Full Environmental Picture

True objectivity requires acknowledging the complete lifecycle. While operationally clean, the overall environmental impact depends on a few key factors.

The Source of Electricity Matters

The "zero-emission" benefit of MoSi₂ elements is at the point of use. The overall carbon footprint is still tied to the source of the electricity. If the power is generated from fossil fuels like coal, the environmental impact is simply shifted upstream to the power plant.

However, when paired with renewable energy sources like solar, wind, or hydropower, the entire heating process becomes truly low-impact.

Material Sourcing and Production

The manufacturing of any advanced material has an environmental cost. The production of molybdenum disilicide is an energy-intensive process. This initial environmental investment is, however, largely offset by the element's long service life and high operational efficiency, which reduce total energy consumption over time.

Making an Informed Decision

Choosing a heating technology requires balancing operational needs with environmental goals. MoSi₂ elements offer a compelling case on multiple fronts.

- If your primary focus is operational cleanliness and local air quality: MoSi₂ elements are a superior choice as they produce no on-site emissions, protecting both personnel and sensitive products.

- If your primary focus is energy efficiency and cost reduction: Their high heating rates and low power consumption directly translate to lower operational energy use and reduced utility costs.

- If your primary focus is long-term sustainability and minimal maintenance: The exceptional durability and long service life of MoSi₂ elements reduce waste, resource consumption, and the total cost of ownership.

Ultimately, their combination of clean operation, high efficiency, and longevity makes them a highly responsible choice for modern high-temperature applications.

Summary Table:

| Environmental Benefit | Key Feature | Impact |

|---|---|---|

| Zero Emissions | Electric resistance heating | No on-site CO2, NOx pollutants; improves air quality |

| High Energy Efficiency | Rapid heating and low power consumption | Reduces electricity use and carbon footprint |

| Longevity and Reduced Waste | Durable with self-healing properties | Minimizes replacements, lowers resource use and landfill waste |

Ready to enhance your lab's sustainability with eco-friendly heating solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to learn how our MoSi2 heating elements can reduce your environmental impact and boost efficiency!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism