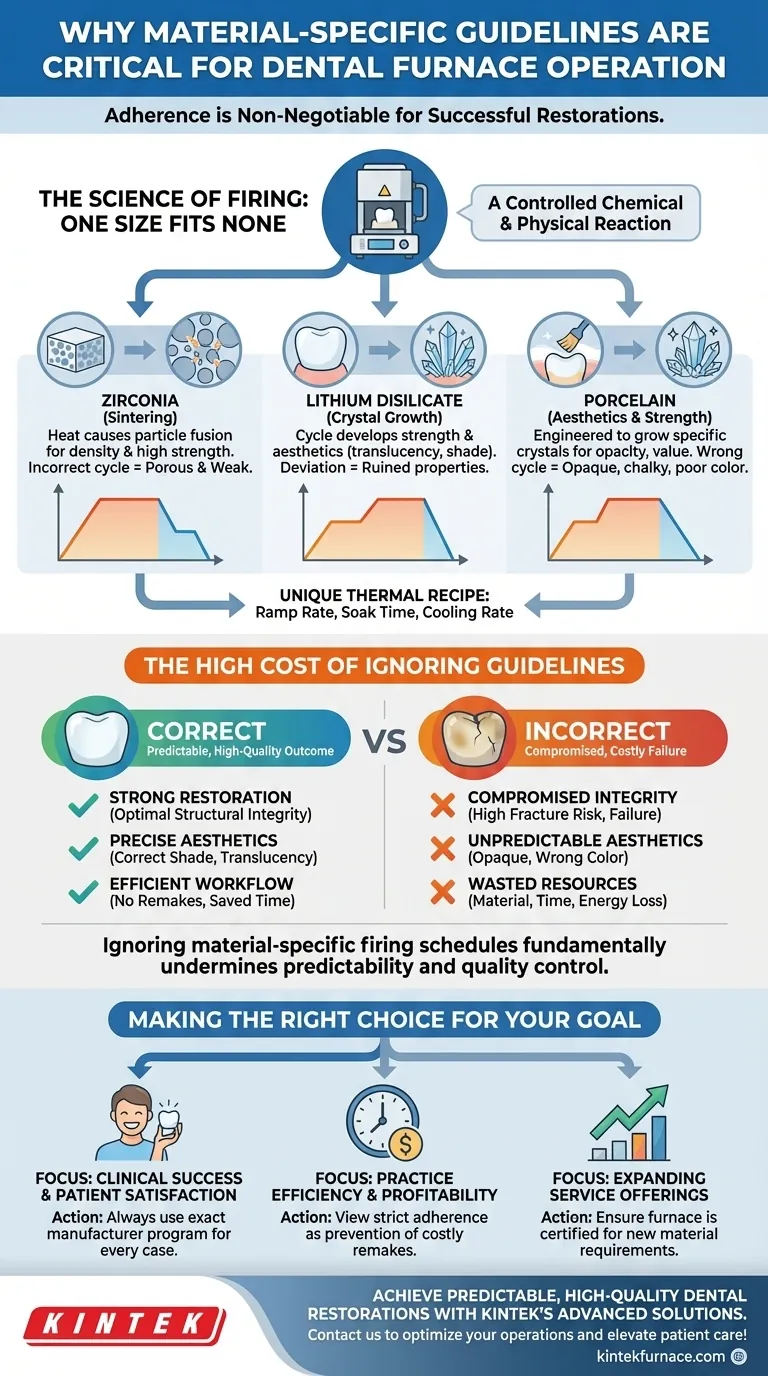

Adhering to material-specific guidelines is non-negotiable for successful dental furnace operation. Every dental ceramic, from zirconia to lithium disilicate, possesses a unique chemical composition that dictates the precise heating, holding, and cooling cycle required to achieve its intended strength, fit, and aesthetic properties. Using a generic or incorrect program is a primary cause of failed restorations, leading to fractures, poor color matching, and wasted resources.

The core issue extends beyond a single failed crown. Ignoring material-specific firing schedules fundamentally undermines the predictability and quality control that justify the investment in in-office milling and furnace technology in the first place.

The Science of Firing: Why One Size Fits None

To understand the importance of specific guidelines, you must first understand the transformative process that happens inside the furnace. This isn't simply a matter of heating and cooling; it's a controlled chemical and physical reaction.

Each Material Has a Unique Thermal Recipe

Dental materials like zirconia, lithium disilicate, and various porcelains are not interchangeable. They have different crystalline structures and particle compositions.

The manufacturer's guidelines provide a precise "recipe" that controls the thermal journey, including the ramp rate (how fast it heats), soak time (how long it stays at peak temperature), and cooling rate.

The Critical Role of Sintering

For materials like zirconia, the process is called sintering. The furnace heats the milled restoration to a temperature just below its melting point.

This heat causes the individual ceramic particles to fuse, densifying the structure and shrinking it to its final, high-strength form. An incorrect temperature or time results in incomplete sintering, leaving the restoration porous and weak.

Firing for Aesthetics and Strength

For materials like porcelain or lithium disilicate, the firing cycle develops both strength and the final aesthetic. The cycle is engineered to grow specific crystal structures that give the material its desired translucency, opalescence, and shade. Deviating from this path can ruin these sensitive properties.

The High Cost of Ignoring the Guidelines

The temptation to use a "universal" or familiar program is a common but costly mistake. The consequences directly impact your practice's efficiency, profitability, and reputation.

Compromised Structural Integrity

The most immediate risk is a physically weak restoration. A crown or bridge that was fired too quickly or at the wrong temperature is significantly more prone to fracturing under normal occlusal loads, often leading to a catastrophic failure in the patient's mouth.

Unpredictable Aesthetic Outcomes

Aesthetics are not just about shade selection. The firing cycle is critical for achieving the correct translucency and value. An incorrect cycle can make a restoration appear opaque, chalky, or simply the wrong color, requiring a complete remake.

Wasted Time and Resources

Every failed restoration represents a significant loss. This includes the cost of the material block, the wear on milling burs, the energy consumed by the furnace, and—most importantly—valuable and unproductive chair time for both you and the patient.

Making the Right Choice for Your Goal

Ultimately, following the manufacturer's instructions is the most direct path to leveraging your furnace as a tool for predictable, high-quality care.

- If your primary focus is clinical success and patient satisfaction: Always use the exact firing program specified by the material's manufacturer for every case.

- If your primary focus is practice efficiency and profitability: View strict adherence to guidelines as the best way to prevent costly remakes and protect your schedule from unproductive appointments.

- If your primary focus is expanding your service offerings: Ensure your furnace is certified to handle the specific thermal requirements of any new material before you invest in it.

Respecting the unique science of each material is fundamental to mastering the art of in-office restorations.

Summary Table:

| Material | Key Process | Risks of Incorrect Firing |

|---|---|---|

| Zirconia | Sintering for strength | Porous, weak restorations |

| Lithium Disilicate | Crystal growth for aesthetics | Poor translucency, color issues |

| Porcelains | Firing for shade and strength | Opaque, chalky appearance |

Achieve predictable, high-quality dental restorations with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique material requirements, enhancing efficiency and reducing costly remakes. Contact us today to optimize your dental furnace operations and elevate patient care!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision