In short, induction furnaces are exceptionally well-suited for investment casting because they offer an unmatched combination of precision, speed, and versatility. This technology allows for rapid, efficient melting with exact temperature control, and the availability of both air and vacuum systems makes it compatible with nearly any metal or alloy. These capabilities directly address the rigorous quality and geometric complexity demands of the investment casting process.

The suitability of an induction furnace for investment casting isn't just about melting metal; it's about achieving absolute process control. Its ability to deliver a clean, precisely heated, and homogenous melt on demand is what ensures the final cast part meets the tight tolerances and quality standards inherent to the process.

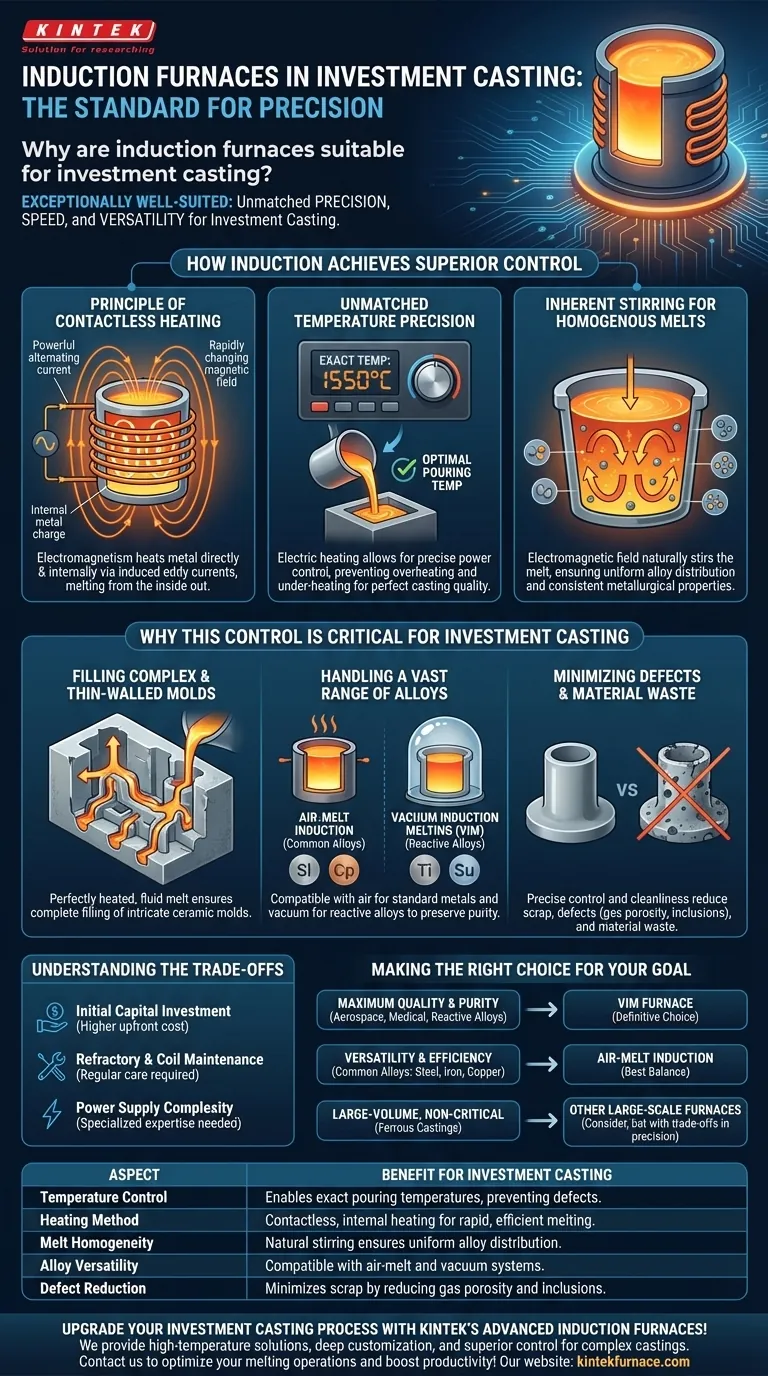

How Induction Furnaces Achieve Superior Control

To understand why induction is the preferred method, we must look at its core principles. Unlike fuel-fired furnaces that heat from the outside, an induction furnace uses electromagnetism to heat the metal directly and internally.

The Principle of Contactless Heating

An induction furnace works by passing a powerful alternating current through a copper coil. This creates a strong, rapidly changing magnetic field around the metal charge inside the crucible.

This magnetic field induces powerful electrical currents, known as eddy currents, directly within the metal itself. The metal's natural resistance to these currents generates intense heat, causing it to melt rapidly from the inside out.

Unmatched Temperature Precision

Because the heating is generated by electricity, the power level can be controlled with extreme precision. This allows operators to dial in the exact pouring temperature required for a specific alloy and part geometry.

This prevents overheating, which can degrade alloy properties, and under-heating, which can lead to casting defects like cold shuts.

Inherent Stirring for Homogenous Melts

A key benefit of the electromagnetic field is that it naturally and vigorously stirs the molten metal bath. This action ensures all alloying elements are distributed evenly, creating a perfectly homogenous melt.

This eliminates hot or cold spots and guarantees consistent metallurgical properties throughout the final casting, which is critical for high-performance components.

Why This Control is Critical for Investment Casting

Investment casting is defined by its ability to produce complex, near-net-shape parts. The success of this process hinges on the quality of the molten metal.

Filling Complex and Thin-Walled Molds

Investment casting molds often feature intricate details and very thin sections. A perfectly heated, fluid melt is essential to fill every crevice of the ceramic mold cavity before the metal begins to solidify, ensuring a complete and accurate casting.

Handling a Vast Range of Alloys

Foundries use investment casting for everything from standard stainless steels to reactive alloys like titanium and nickel-based superalloys. Induction furnaces provide the necessary process environment for all of them.

Air-melt induction is perfect for most common alloys. For reactive metals that would be contaminated by oxygen, a vacuum induction melting (VIM) furnace removes the atmosphere, preserving the metal's purity.

Minimizing Defects and Material Waste

The control offered by induction melting directly reduces scrap rates. Precise temperature control and the inherent cleanliness of the process minimize defects like gas porosity and non-metallic inclusions. This not only improves casting quality but also reduces wasted material, energy, and labor.

Understanding the Trade-offs

While highly effective, induction technology is not without its specific considerations. Objectivity requires acknowledging them.

Initial Capital Investment

Induction furnace systems typically represent a higher upfront capital cost compared to simpler gas-fired or resistance furnaces. The investment is in process control and long-term efficiency, not just melting capacity.

Refractory and Coil Maintenance

The crucible, or refractory lining, that contains the molten metal is a consumable component that wears out over time and requires careful monitoring and replacement. Likewise, the water-cooled copper coil is a critical component that requires regular inspection and maintenance to prevent a catastrophic failure.

Power Supply Complexity

The high-frequency power supplies that drive induction furnaces are sophisticated pieces of electronic equipment. Troubleshooting and repair often require specialized technical expertise, unlike the more mechanical nature of a gas burner system.

Making the Right Choice for Your Goal

Selecting the right melting system depends entirely on the materials you work with and the quality standards you must meet.

- If your primary focus is maximum quality and material purity: A vacuum induction melting (VIM) furnace is the definitive choice, especially for aerospace, medical, and other applications using reactive alloys or superalloys.

- If your primary focus is versatility and efficiency for common alloys: An air-melt induction furnace provides the best balance of speed, control, and cost for most steels, irons, and copper-based alloys.

- If your primary focus is producing large-volume, non-critical ferrous castings: While induction is still a strong choice, you might also evaluate other large-scale furnaces, but be prepared for a trade-off in precision and flexibility.

Ultimately, choosing an induction furnace is an investment in process repeatability and the uncompromising quality of your final cast product.

Summary Table:

| Aspect | Benefit for Investment Casting |

|---|---|

| Temperature Control | Enables exact pouring temperatures, preventing defects like overheating or cold shuts. |

| Heating Method | Contactless, internal heating via electromagnetism for rapid, efficient melting. |

| Melt Homogeneity | Natural stirring ensures uniform alloy distribution for consistent part quality. |

| Alloy Versatility | Compatible with air-melt for common alloys and vacuum for reactive metals like titanium. |

| Defect Reduction | Minimizes scrap rates by reducing gas porosity and inclusions, saving material and costs. |

Upgrade your investment casting process with KINTEK's advanced induction furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering superior control, efficiency, and quality for complex castings. Contact us today to discuss how we can optimize your melting operations and boost productivity!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing