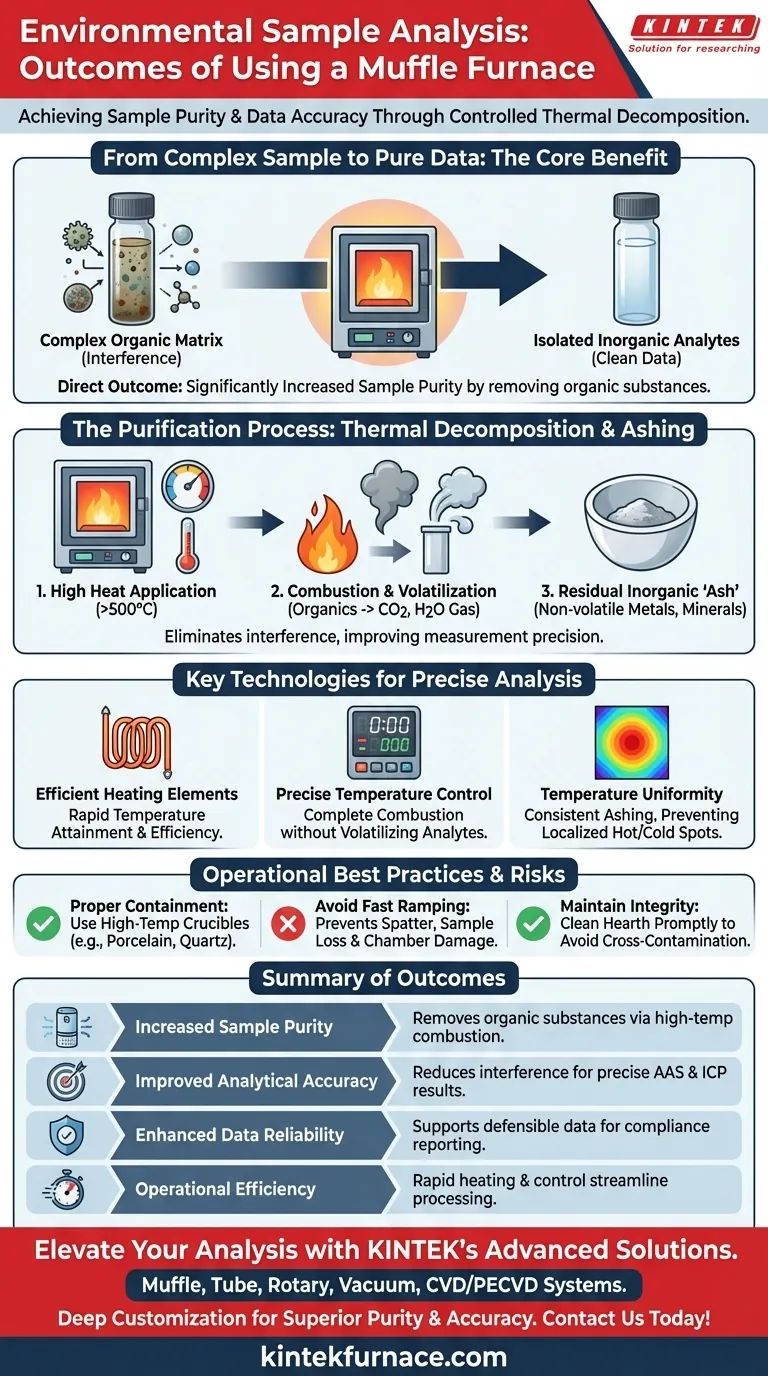

In environmental sample analysis, the use of a muffle furnace primarily resulted in a significant increase in sample purity. By efficiently removing organic substances through high-temperature combustion, the furnace produces a cleaner sample, which directly leads to more accurate and reliable analytical results for pollutants and other inorganic components.

The core function of a muffle furnace in this context is not merely heating, but controlled thermal decomposition. It systematically strips away the organic matrix of a sample, isolating the inorganic analytes and eliminating interference that would otherwise compromise the accuracy of your data.

How Muffle Furnaces Enhance Sample Purity

The effectiveness of a muffle furnace hinges on a clear scientific principle: using high heat to separate volatile organic compounds from stable inorganic materials. This process is often referred to as ashing or mineralization.

The Principle of Thermal Decomposition

At temperatures typically exceeding 500°C, the intense heat inside a muffle furnace causes organic matter within a sample to combust and volatilize. These organic compounds are converted into gases like carbon dioxide and water vapor, which are then vented away.

This leaves behind the non-volatile, inorganic components of the sample, such as heavy metals, minerals, and salts.

Isolating the Analyte of Interest

Many environmental samples, like soil or water sludge, have a complex organic matrix. This matrix can physically or chemically interfere with analytical instruments, masking the presence of the inorganic pollutants you are trying to measure.

By burning off this interfering matrix, the furnace effectively isolates and concentrates the inorganic analytes. The resulting "ash" is a much simpler and cleaner sample to analyze.

The Direct Impact on Data Accuracy

With interfering compounds removed, analytical techniques like Atomic Absorption Spectroscopy (AAS) or Inductively Coupled Plasma (ICP) can measure target elements with far greater precision and lower detection limits.

This improved accuracy provides stronger, more defensible data for critical applications like pollution monitoring, soil quality assessment, and environmental compliance reporting.

Key Technologies Enabling Precise Analysis

The success of this process is not accidental. It relies on specific technological features engineered into modern muffle furnaces to ensure consistent and reliable outcomes.

Efficient Heating Elements

Modern furnaces use high-performance heating elements that allow for rapid temperature attainment. This reduces sample processing time and improves overall lab efficiency without sacrificing control.

Precise Temperature Control

Crucially, the furnace allows for precise control over the heating process. This ensures that the temperature is high enough for complete combustion of organics but not so high that it volatilizes the inorganic analytes of interest.

Temperature Uniformity

Advanced furnace designs ensure even temperature distribution throughout the chamber. This uniformity prevents localized "hot spots" or "cold spots," guaranteeing that the entire sample is treated equally for consistent and complete ashing.

Understanding the Operational Risks and Best Practices

While highly effective, achieving optimal results with a muffle furnace requires adherence to strict operational protocols. Operator error can lead to inaccurate results or damage to the equipment.

Proper Sample Containment

Samples must be placed in containers capable of withstanding extreme temperatures without reacting with the sample. High-temperature-resistant porcelain or quartz crucibles are standard for this purpose.

The Danger of Excessive Temperature Ramps

Heating the sample too quickly can cause it to spatter or "splash." This not only results in a loss of sample mass, leading to inaccurate final measurements, but the spatter can also corrode the furnace's internal chamber.

Maintaining Furnace Integrity

The hearth of the furnace must be kept clean. Any spilled slag, metal oxides, or other impurities should be cleared promptly to prevent them from bonding to the furnace floor, which can cause damage and create cross-contamination risks for future samples.

Making the Right Choice for Your Goal

To leverage a muffle furnace effectively, align your procedure with your specific analytical objective.

- If your primary focus is trace metal analysis: Use the muffle furnace to completely eliminate the organic matrix, which is a major source of interference for spectroscopic methods.

- If your primary focus is determining the ash or mineral content of a sample: The muffle furnace is the definitive instrument for this analysis, providing the total inorganic residue by weight.

- If your primary focus is lab efficiency and safety: Select a furnace with programmable controls and rapid heating, but enforce strict maintenance and cleaning protocols to ensure its longevity and reliability.

Ultimately, understanding the furnace as a tool for purification empowers you to generate cleaner data and more confident conclusions.

Summary Table:

| Outcome | Description |

|---|---|

| Increased Sample Purity | Removes organic substances via high-temperature combustion for cleaner samples. |

| Improved Analytical Accuracy | Reduces interference, leading to precise results in techniques like AAS and ICP. |

| Enhanced Data Reliability | Supports defensible data for pollution monitoring and compliance reporting. |

| Operational Efficiency | Rapid heating and precise control streamline sample processing in labs. |

Elevate your environmental analysis with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, helping you achieve superior sample purity and data accuracy. Contact us today to discuss how our solutions can optimize your lab's performance and drive confident results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a stainless steel reactor function within a muffle furnace for PET to graphene? Master Carbon Synthesis

- What role does a muffle furnace play in g-C3N4 synthesis? Mastering Thermal Polycondensation for Semiconductors

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- What is the primary use of a muffle furnace in the assembly of side-heated resistive gas sensors? Expert Annealing Guide

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis