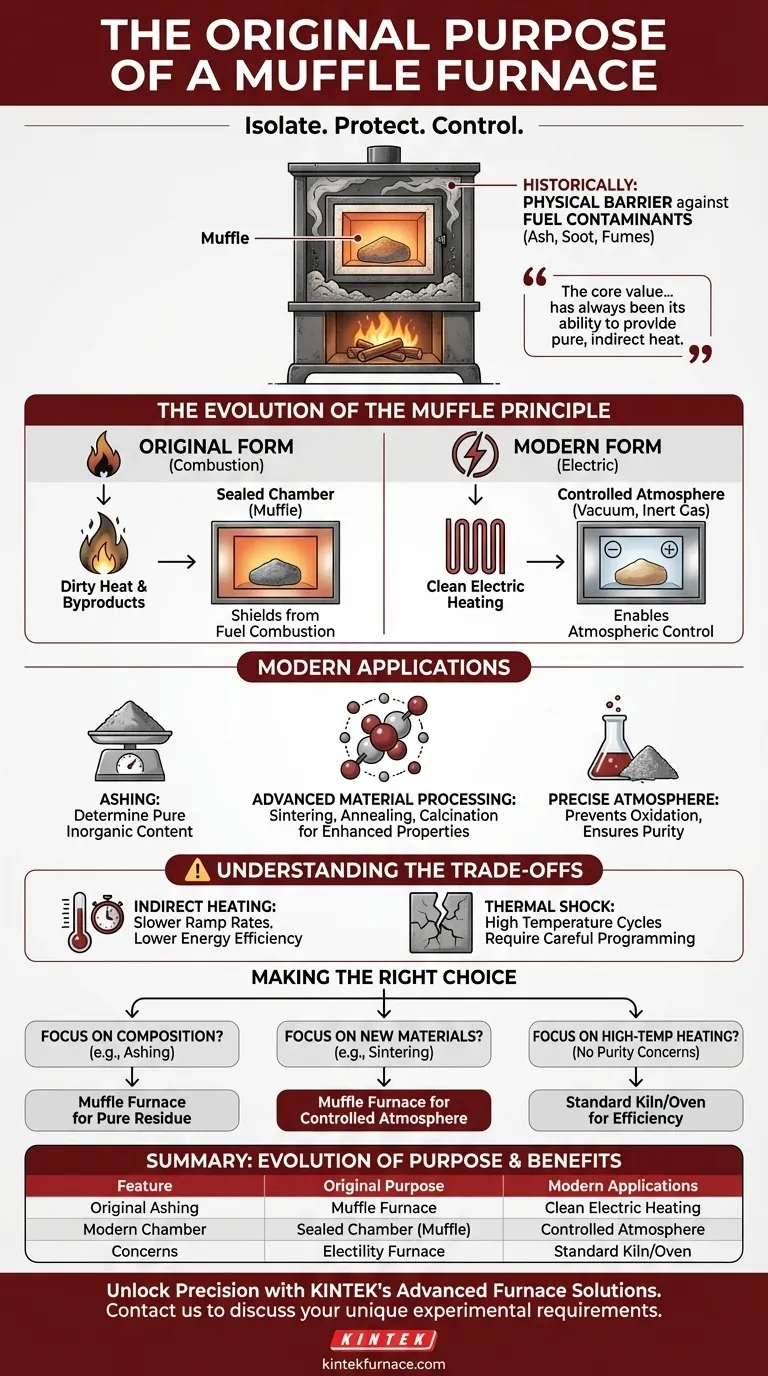

Historically, the original purpose of a muffle furnace was to isolate a sample from contamination. Early high-temperature work relied on burning fuel like coal or gas, which produced ash, soot, and reactive fumes. The "muffle"—an inner chamber or retort—was designed to act as a physical barrier, protecting the material inside from these contaminants while still allowing heat to radiate through.

The core value of a muffle furnace has always been its ability to provide pure, indirect heat. This principle of isolation was first used to prevent contamination from fuel byproducts and has since evolved to enable precise atmospheric control for modern scientific and industrial processes.

The Core Principle: What "Muffle" Means

A muffle furnace is defined not just by its high temperatures, but by its internal design that separates the sample from the heat source. This fundamental concept is the key to all of its applications.

From Combustion to Contamination-Free Heat

In its original form, the furnace generated heat by burning fuel in an outer chamber. This combustion process was inherently dirty.

Without a barrier, soot and ash would settle on the sample, and exhaust gases could cause unwanted chemical reactions. The muffle was the simple, effective solution: a sealed container that shielded the sample while it "baked" in the heat.

The Modern Electric Advantage

Today, most muffle furnaces use electric resistance heating elements. This eliminates the original problem of contamination from fuel combustion.

However, the muffle chamber remains essential. Its purpose has evolved from keeping contaminants out to keeping a controlled atmosphere in. The sealed chamber allows users to perform processes in a vacuum, an inert gas like argon, or other specific atmospheric conditions that are critical for modern materials science.

How This Principle Is Applied Today

The need for a pure, controlled heating environment is central to many analytical and production processes. The muffle furnace is the standard tool for these tasks.

Determining Ash Content

One of the most common applications is ashing. This process is used to determine the amount of inorganic, non-combustible material in a sample.

The furnace heats a sample (like food, plastic, or coal) to a temperature high enough to completely burn away all organic matter. Because the heating is clean and contained, what remains—the ash—is a pure residue that can be accurately weighed and analyzed.

Advanced Material Processing

In materials science and engineering, muffle furnaces are critical for treatments that enhance a material's properties.

Processes like sintering (fusing powders into a solid mass), annealing (altering a microstructure to make a material less brittle), and calcination (heating to drive off impurities) all require precise temperature and atmospheric control. The isolated chamber prevents oxidation and other unwanted reactions, ensuring the final material achieves its desired crystal structure and mechanical properties.

Understanding the Trade-offs

While indispensable for its purpose, the design of a muffle furnace comes with inherent trade-offs compared to direct-heating ovens.

Indirect Heating and Efficiency

Because heat must radiate through the muffle chamber walls to reach the sample, the process is less direct than an open-element kiln. This can result in slightly slower heating ramp rates and potentially lower overall energy efficiency.

This inefficiency is the necessary price for the purity and atmospheric control that the furnace provides. It is a deliberate design choice, not a flaw.

Thermal Shock and Material Limits

The very high temperatures and potentially rapid heating/cooling cycles can induce thermal shock, which can crack or damage sensitive materials like certain ceramics or glass.

Proper procedure requires careful programming of temperature ramps and allowing samples to cool slowly, often within the furnace or a desiccator, to mitigate this risk.

Making the Right Choice for Your Goal

Whether a muffle furnace is the correct tool depends entirely on your need for purity and atmospheric control during heating.

- If your primary focus is measuring composition (e.g., ashing): The muffle furnace is essential for cleanly burning off organic matter to leave a pure inorganic residue for analysis.

- If your primary focus is creating new materials (e.g., sintering): The furnace's isolated chamber is critical for controlling the atmosphere, preventing unwanted chemical reactions, and achieving specific material properties.

- If your primary focus is simply high-temperature heating without purity concerns: A standard kiln or direct-heating oven may be a more efficient and cost-effective solution.

Ultimately, a muffle furnace is chosen when the purity of the outcome is as important as the heat required to achieve it.

Summary Table:

| Feature | Original Purpose | Modern Applications |

|---|---|---|

| Muffle Chamber | Isolate sample from fuel contaminants | Enable controlled atmospheres (e.g., vacuum, inert gas) |

| Heating Method | Fuel combustion (e.g., coal, gas) | Electric resistance heating |

| Key Benefits | Provide pure, indirect heat | Precise temperature and atmospheric control for material purity |

| Common Uses | Protection from soot and ash | Ashing, sintering, annealing, calcination |

Unlock Precision in Your Lab with KINTEK's Advanced Furnace Solutions

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions tailored to your needs. Our product line includes Muffle Furnaces, Tube Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're focused on ashing, sintering, or other material processes, our furnaces ensure contamination-free heating and superior performance.

Ready to enhance your lab's efficiency and achieve pure results? Contact us today to discuss how our solutions can benefit your specific applications!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing