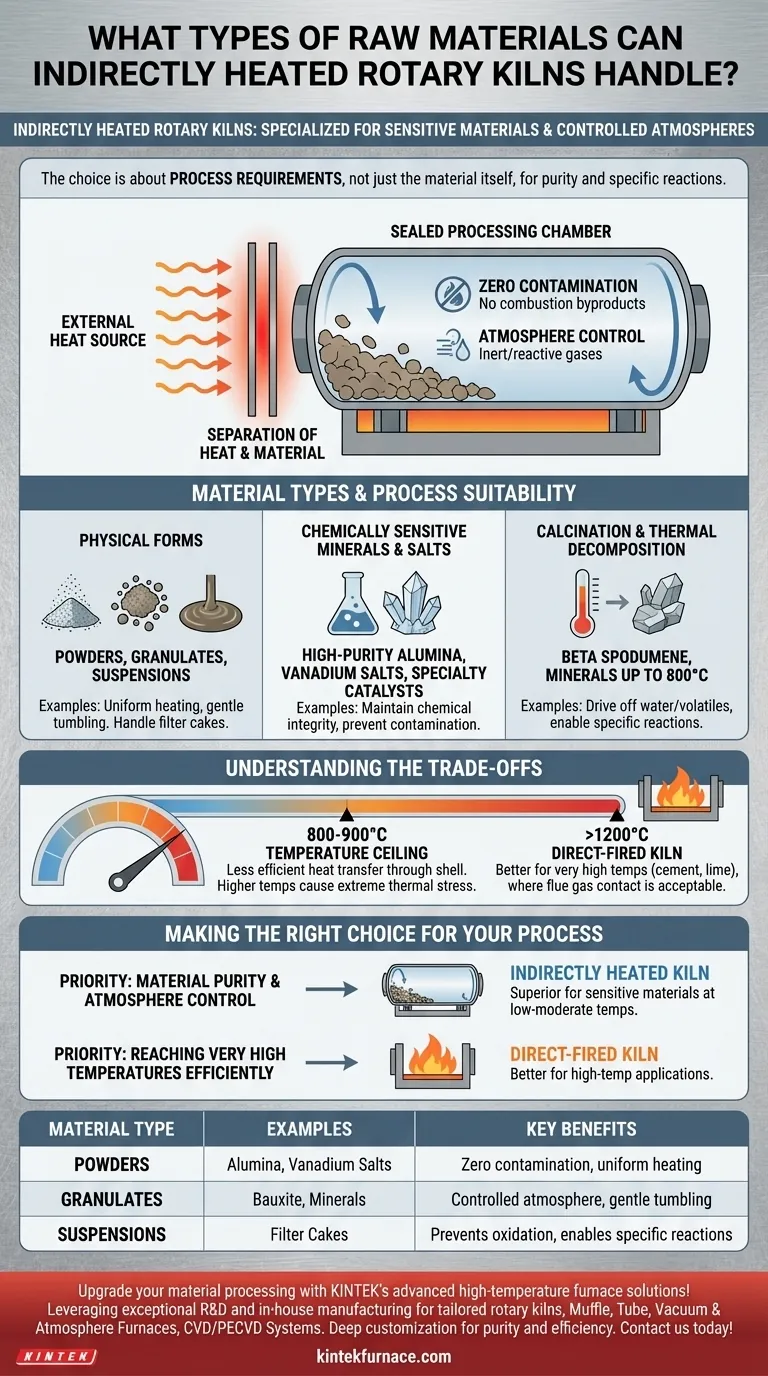

In short, indirectly heated rotary kilns are designed to process materials that are sensitive to contamination or require a controlled atmosphere. This includes a range of physical forms like powders, granulates, and suspensions, with specific examples being alumina, bauxite, vanadium salts, and minerals like beta spodumene that undergo calcination at temperatures up to 800°C.

The decision to use an indirectly heated rotary kiln is not about the material itself, but about the process requirements. This method is chosen specifically when preventing contact between the material and combustion gases is critical for ensuring product purity or enabling specific chemical reactions.

The Defining Principle: Separation of Heat and Material

The function of an indirectly heated kiln is best understood by its core design principle: the heat source is external to the processing chamber. The rotating drum (kiln shell) is heated from the outside, and this heat is then transferred through the shell wall to the material tumbling inside.

What This Means for Your Material

This design is fundamentally different from a direct-fired kiln, where the flame and hot combustion gases pass directly over and through the material bed.

The key consequence is zero contamination from the heat source. Byproducts of combustion, such as sulfur or excess carbon, never come into contact with your raw material.

The Advantage of Atmosphere Control

Because the processing chamber is sealed from the combustion environment, you gain precise control over the internal atmosphere.

This allows for processing in inert environments (like nitrogen) to prevent oxidation, or in reactive gas environments to promote specific chemical changes.

Material Types and Process Suitability

Indirectly heated kilns are versatile in the types of materials they can handle, as long as the process aligns with their core advantages.

Physical Forms

The gentle tumbling action is effective for ensuring uniform heat exposure for various material forms. These include fine powders, larger granulates, and even some suspensions or filter cakes. The robust steel shell is built to handle the abrasive nature of many of these materials.

Chemically Sensitive Minerals and Salts

This is the primary application category. Materials that would be compromised by direct flame contact are ideal candidates.

Examples like vanadium salts, high-purity alumina, or specialty catalysts require this level of process control to maintain their chemical integrity and performance specifications.

Calcination and Thermal Decomposition

Processes like the calcination of beta spodumene or other minerals up to 800°C are common. In these cases, the goal is to drive off water or volatiles at a specific temperature without introducing unwanted chemical side reactions.

Understanding the Trade-offs

While powerful, the indirect heating method has one significant limitation that you must consider for your application.

The Temperature Ceiling

Transferring heat through a thick, rotating steel shell is less efficient than direct heat transfer. This creates a practical temperature ceiling, which is often around 800-900°C.

Pushing for higher temperatures becomes increasingly inefficient and can put extreme thermal stress on the kiln's mechanical components, like its shell and riding rings.

When to Choose a Direct-Fired Kiln

If your process requires extremely high temperatures (e.g., >1200°C), such as in cement or lime production, a direct-fired kiln is almost always the more effective and economical choice. The direct contact between the flame and material allows for much higher heat transfer rates.

Making the Right Choice for Your Process

Your decision should be guided by your most critical process variable.

- If your primary focus is material purity and atmosphere control: An indirectly heated kiln is the superior choice for processing sensitive materials at low-to-moderate temperatures.

- If your primary focus is reaching very high temperatures efficiently: A direct-fired kiln is better suited for high-temperature applications where direct contact with flue gas is acceptable.

- If your material is a powder, granulate, or slurry: Both kiln types can handle these forms, so your decision should revert back to the temperature and purity requirements of your process.

Ultimately, selecting the correct kiln technology hinges on understanding whether your material's final quality depends on its isolation from the heat source.

Summary Table:

| Material Type | Examples | Key Benefits |

|---|---|---|

| Powders | Alumina, Vanadium Salts | Zero contamination, uniform heating |

| Granulates | Bauxite, Minerals | Controlled atmosphere, gentle tumbling |

| Suspensions | Filter Cakes | Prevents oxidation, enables specific reactions |

Upgrade your material processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored rotary kilns and other systems like Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for purity and efficiency. Contact us today to discuss how we can enhance your process with reliable, contamination-free heating!

Visual Guide

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment