In short, an induction furnace can melt virtually any metal that conducts electricity. This includes common industrial metals like iron, steel, aluminum, and copper, as well as precious metals like gold, silver, and platinum. Their versatility even extends to specialty superalloys and reactive metals under controlled conditions.

The core principle of induction heating is its ability to generate heat directly within an electrically conductive material using a powerful magnetic field. This is why induction furnaces are not limited to specific metals but can handle a vast range, defined only by the material's conductivity and the furnace's power and design.

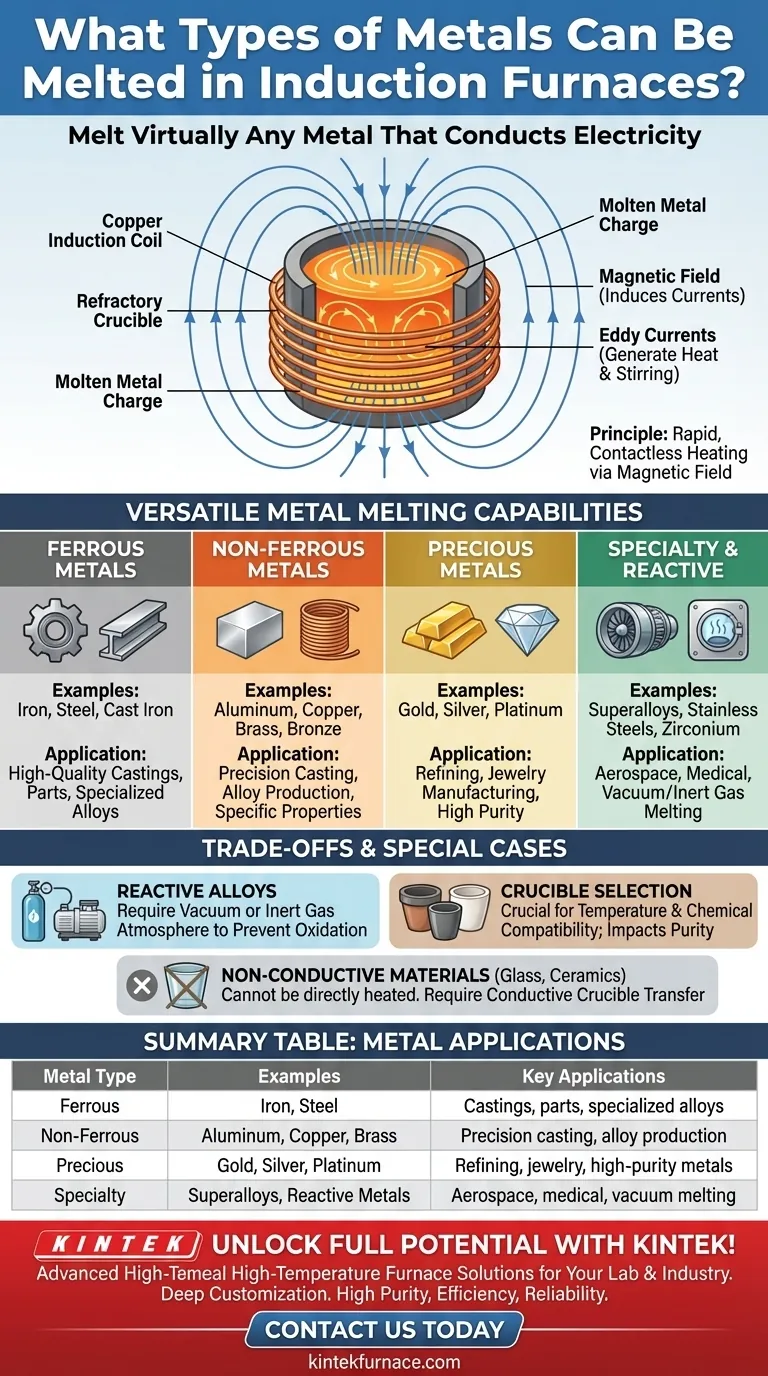

The Principle: Why Induction Melting is So Versatile

The true power of induction technology lies in its heating method, which is fundamentally different from traditional fuel-fired or resistance furnaces.

It's All About Electrical Conductivity

An induction furnace uses a coil of copper wire through which a powerful alternating current is passed. This creates a rapidly changing magnetic field around the crucible holding the metal.

This magnetic field induces powerful eddy currents within the metal charge itself. The metal's natural electrical resistance causes these currents to generate immense, precise, and rapid heat, melting it from the inside out.

No Direct Contact with a Heating Element

Unlike other methods, the heat source (the magnetic field) never touches the metal. The material is contained in a non-conductive refractory crucible.

This prevents contamination from burning fuel or a degrading heating element, making it ideal for producing high-purity metals and sensitive alloys.

Built-in Stirring for Alloy Homogeneity

The same electromagnetic forces that generate heat also create a natural stirring action within the molten bath. This ensures the melt is at a uniform temperature and that alloying elements are mixed in thoroughly and evenly.

Common Metals and Industrial Applications

The versatility of induction melting supports a wide array of industries, each leveraging the technology for its specific material needs.

Ferrous Metals (Iron and Steel)

This is the largest application. Foundries and steel mills use induction furnaces to melt cast iron and steel for creating high-quality castings, parts, and specialized steel alloys. Their speed and cleanliness are major advantages.

Non-Ferrous Metals (Aluminum, Copper, Brass)

Induction is widely used for melting aluminum, copper, and their alloys like brass and bronze. The precise temperature control is critical for maintaining the specific properties of these metals during casting.

Precious Metals (Gold, Silver, Platinum)

The precious metals industry relies heavily on induction furnaces for refining, melting, and jewelry manufacturing. The non-contact heating method guarantees minimal metal loss and maintains the high purity required for these valuable materials.

Understanding the Trade-offs and Special Cases

While incredibly versatile, the effectiveness of an induction furnace depends on understanding its operational context and limitations.

Specialty and Reactive Alloys

Induction furnaces are excellent for melting high-temperature superalloys and metals with a high affinity for oxygen, such as stainless steels or even reactive metals like zirconium.

However, these materials often require melting in a vacuum or an inert gas atmosphere to prevent oxidation. Induction furnaces are frequently designed within vacuum chambers for precisely this purpose.

The Critical Role of the Crucible

The crucible is the vessel that holds the molten metal. It must be made of a refractory material that can withstand extreme temperatures and does not react with the specific metal being melted.

The choice of crucible material (e.g., clay-graphite, silicon carbide, alumina) is just as important as the furnace itself and directly impacts the quality of the final product.

The Limitation: Non-Conductive Materials

Standard induction furnaces cannot directly heat electrically insulating materials like glass or ceramics. The magnetic field passes through them with no effect.

However, it is possible to melt these materials by using a conductive crucible (like graphite). In this setup, the furnace heats the crucible, which then transfers its heat to the non-conductive material inside via conduction.

Making the Right Choice for Your Application

The suitability of an induction furnace is defined by your primary goal.

- If your primary focus is large-scale industrial casting: Induction offers unmatched speed, energy efficiency, and quality control for producing iron, steel, and aluminum parts.

- If your primary focus is high-purity or precious metals: The non-contact heating method is the key benefit, as it prevents contamination and ensures the integrity of gold, platinum, or medical-grade alloys.

- If your primary focus is advanced or reactive alloys: An induction furnace within a vacuum chamber provides the controlled environment necessary to melt superalloys and reactive metals without compromising their unique properties.

Ultimately, the induction furnace's ability to cleanly and efficiently melt any conductive material makes it one of the most adaptable tools in modern metallurgy.

Summary Table:

| Metal Type | Examples | Key Applications |

|---|---|---|

| Ferrous | Iron, Steel | Castings, parts, specialized alloys |

| Non-Ferrous | Aluminum, Copper, Brass | Precision casting, alloy production |

| Precious | Gold, Silver, Platinum | Refining, jewelry, high-purity metals |

| Specialty | Superalloys, Reactive Metals | Aerospace, medical, vacuum melting |

Unlock the full potential of your metal melting processes with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Whether you're working with industrial metals, precious materials, or reactive alloys, our induction furnaces ensure high purity, efficiency, and reliability. Contact us today to discuss how we can tailor a solution for your specific needs and elevate your lab's performance!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications