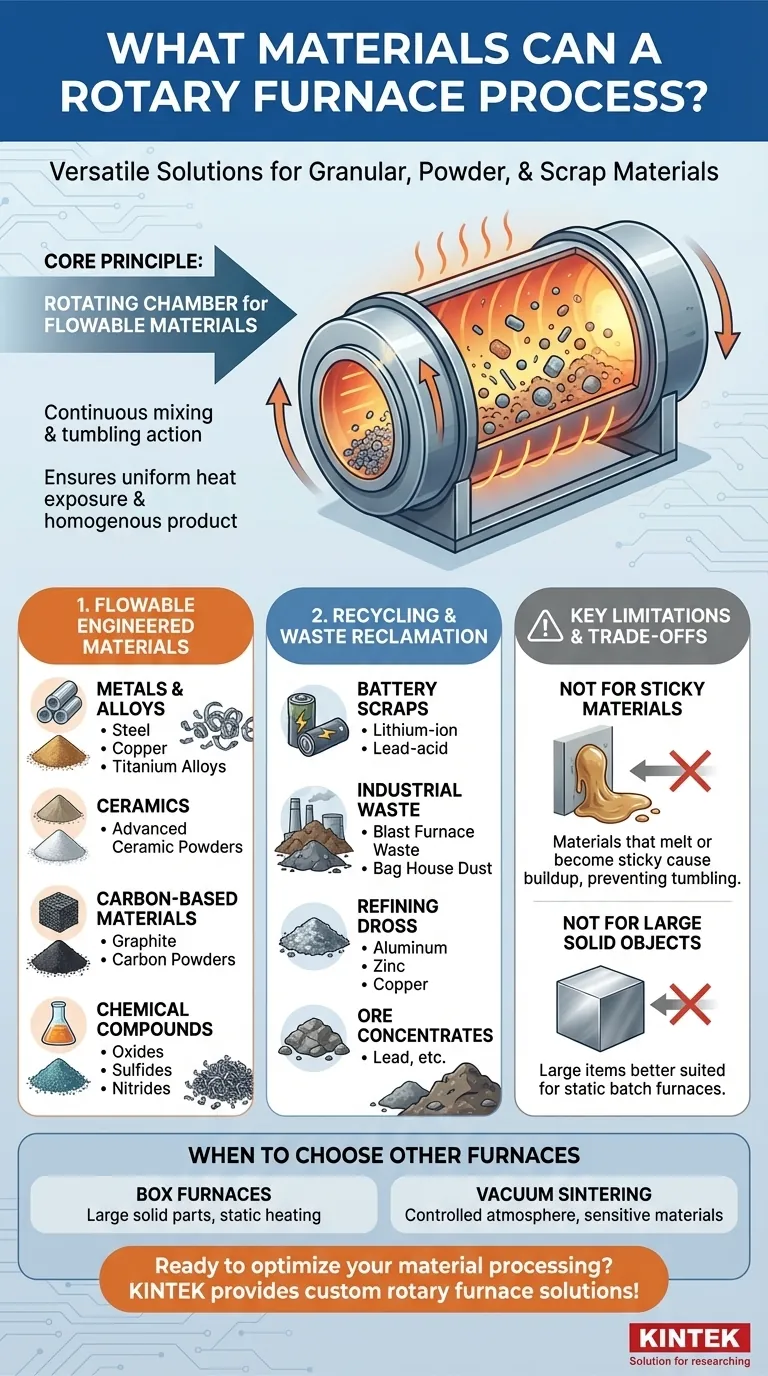

In short, a rotary furnace is exceptionally versatile, designed to process a wide range of materials, especially those in granular, powder, or scrap form. It excels at handling industrial byproducts like battery scraps, blast furnace waste, refining dross, and various ores, as well as engineered materials such as metals, ceramics, and carbon-based powders.

The defining characteristic of a rotary furnace is its ability to process materials that can tumble and flow freely. Its rotating action continuously mixes the contents, ensuring uniform heat exposure, which makes it a powerful tool for recycling, reclamation, and high-throughput thermal processing.

The Core Principle: Why Rotary Furnaces Are So Versatile

A rotary furnace's effectiveness stems from its simple yet powerful design: a rotating cylindrical chamber. This continuous motion is the key to its broad material compatibility.

Processing Granular and Particulate Matter

The primary design intent is to process materials that can flow. This includes powders, grains, and small, irregularly shaped solids.

As the furnace rotates, the material tumbles, constantly exposing new surfaces to the heat source. This prevents hot spots and ensures a homogenous final product.

A Broad Spectrum of Materials

Rotary furnaces are compatible with an extensive list of raw and engineered materials that fit the "flowable" criteria.

Examples include:

- Metals and Alloys: Steel, copper, and titanium alloys.

- Ceramics: Powders used for advanced ceramic production.

- Carbon-Based Materials: Various forms of carbon and graphite powders.

- Chemical Compounds: Oxides, sulfides, nitrides, and carbides.

Excelling in Recycling and Waste Reclamation

This is where rotary furnaces truly dominate. Their ability to handle non-uniform, mixed materials makes them ideal for the challenging feeds found in the recycling industry.

Common applications include recovering valuable metals from:

- Battery Scraps

- Blast Furnace Waste

- Refining Dross (aluminum, zinc, etc.)

- Bag House Dust

- Lead Ore Concentrates

Understanding the Trade-offs and Limitations

No single tool is perfect for every job. The rotary furnace's strengths in processing flowing materials also define its limitations.

The "Stickiness" Problem

The most significant limitation is that rotary furnaces are not suitable for materials that become sticky or melt into a viscous, non-flowing liquid at high temperatures.

Sticky materials will simply coat the inside wall of the furnace. This buildup prevents tumbling, leading to poor heat transfer, non-uniform processing, and significant operational difficulty.

Not for Large, Solid Objects

By design, a rotary furnace cannot process large, solid blocks or components. The tumbling action is ineffective, and such items are better suited for static furnaces.

When Other Furnaces Are a Better Fit

Understanding when not to use a rotary furnace is critical.

- Box Furnaces: These are ideal for batch-processing solid items or materials that must remain static during heating, such as large metal parts or certain ceramic components.

- Vacuum Sintering Furnaces: These are specialized for creating a highly controlled atmosphere (or vacuum) required for sensitive materials like refractory metals (tungsten, molybdenum), rare earth magnets, and advanced ceramics.

Making the Right Choice for Your Material

To determine if a rotary furnace is the correct solution, you must match its capabilities to your material's properties and your processing goal.

- If your primary focus is high-throughput processing of powders or granules: The rotary furnace is an excellent choice due to its continuous mixing and uniform heating.

- If your primary focus is reclaiming metals from industrial waste like dross or scrap: The rotary furnace is a leading industry standard for this exact application.

- If your material becomes sticky, melts into a single mass, or is a large solid part: You should look to a static batch system like a box furnace.

- If your material requires a highly controlled, oxygen-free atmosphere: A specialized vacuum or atmosphere furnace is the appropriate tool.

Ultimately, choosing the right furnace depends on a clear understanding of how your material behaves at temperature.

Summary Table:

| Material Type | Examples | Key Characteristics |

|---|---|---|

| Metals and Alloys | Steel, copper, titanium alloys | Granular or powder form, recyclable |

| Ceramics | Advanced ceramic powders | Flowable, heat-resistant |

| Carbon-Based Materials | Carbon, graphite powders | Particulate, high-temperature stable |

| Industrial Waste | Battery scraps, refining dross | Non-uniform, mixed, ideal for reclamation |

| Chemical Compounds | Oxides, sulfides, nitrides | Powdered, requiring uniform heat exposure |

Ready to optimize your material processing with a custom rotary furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental and industrial requirements. Whether you're handling powders, granules, or industrial waste, contact us today via our contact form to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating