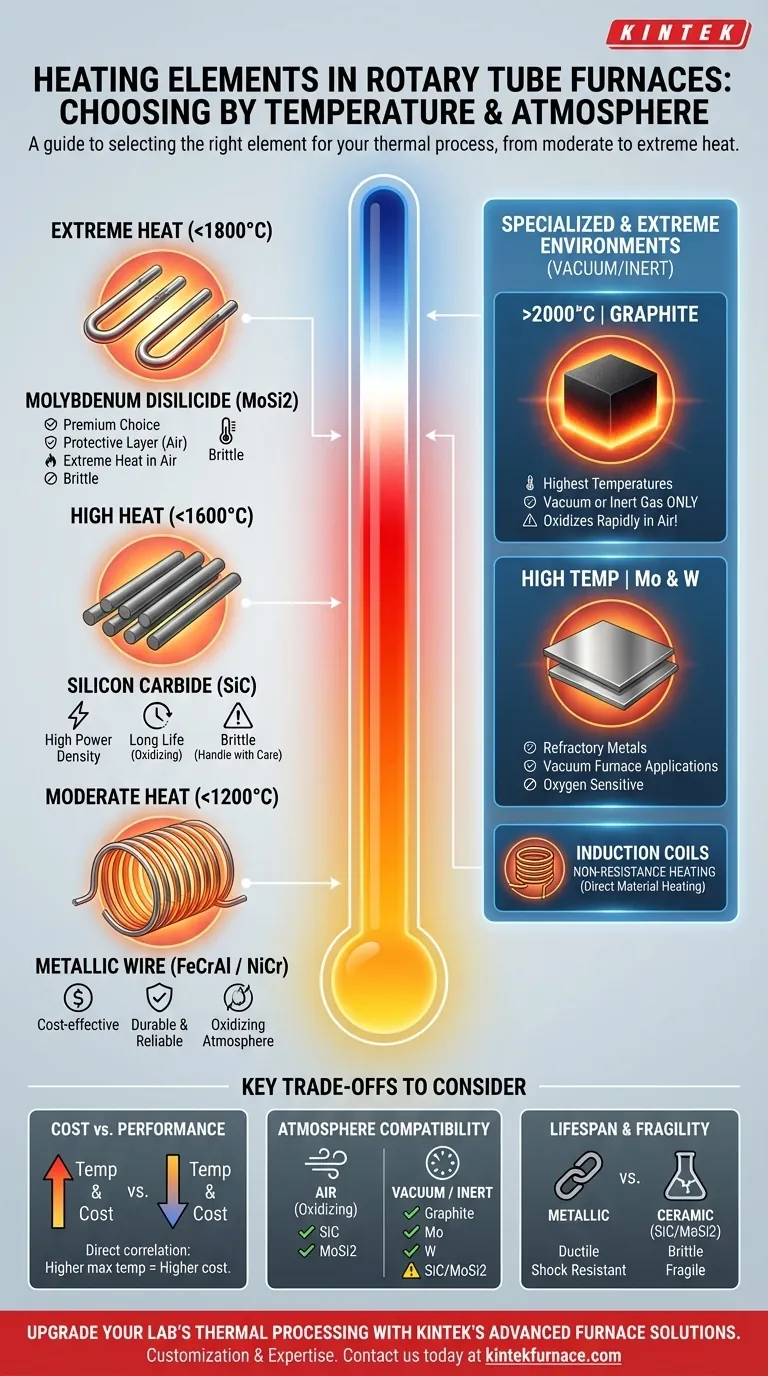

In short, rotary tube furnaces most commonly use metallic resistance wires, silicon carbide (SiC) rods, or molybdenum disilicide (MoSi2) elements. The specific choice is dictated almost entirely by the maximum operating temperature required for the process, with other materials like graphite used for specialized, non-oxidizing environments.

The selection of a heating element is not arbitrary; it is a critical design choice driven by the laws of material science. The single most important factor is your target temperature, as each element type has a clear operational limit beyond which it will fail.

The Role of Temperature in Element Selection

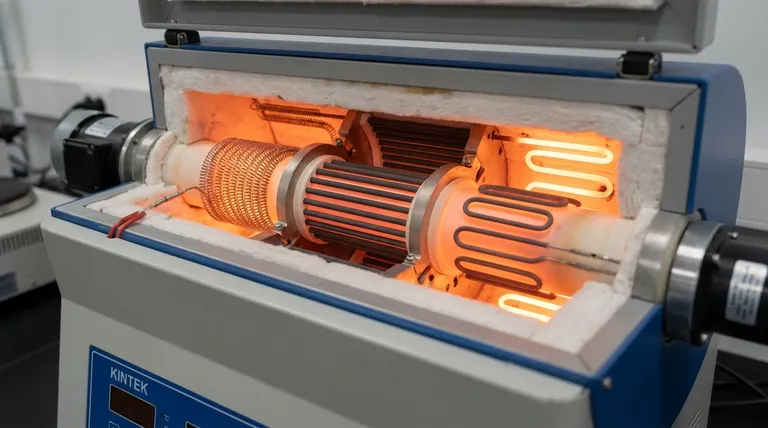

A rotary tube furnace's purpose is to achieve precise thermal processing, often for materials like alumina or iron ore pellets. The heating element is the heart of this system, and its material composition directly determines the furnace's performance capabilities and limitations.

Lower Temperature Applications (Up to ~1200°C): Metallic Wire Elements

For processes that do not require extreme heat, metallic resistance wires are the standard. They are cost-effective, reliable, and durable.

The most common types are iron-chrome-aluminum (FeCrAl) and nickel-chrome (NiCr) alloys. These are typically wound and formed into cylindrical or panel-like heaters that surround the processing tube.

High-Temperature Applications (Up to ~1600°C): Silicon Carbide (SiC)

When temperatures need to exceed the limits of metallic wires, silicon carbide (SiC) becomes the workhorse. These rigid, rod-shaped elements are extremely common in industrial furnaces.

SiC elements are valued for their high power density and long service life in oxidizing atmospheres, making them ideal for demanding processes like calcining.

Very High-Temperature Applications (Up to ~1800°C): Molybdenum Disilicide (MoSi2)

For the highest temperature ranges achievable in an air atmosphere, molybdenum disilicide (MoSi2) is the premium choice.

When heated, these elements form a protective quartz-glass layer on their surface, which prevents further oxidation and allows them to operate reliably at temperatures that would destroy most other materials.

Specialized and Extreme Environments

Some processes require conditions beyond what standard elements can provide.

- Graphite: For temperatures exceeding 2000°C, graphite is a common choice. However, it oxidizes and burns away rapidly in the presence of air, meaning it can only be used in a vacuum or inert gas atmosphere.

- Molybdenum & Tungsten: Like graphite, these pure refractory metals offer exceptional high-temperature performance but must be protected from oxygen. They are typically used in vacuum furnace applications.

- Induction Coils: This represents a different heating method. An induction coil generates a magnetic field that heats a conductive crucible or the material itself directly. It is not a resistance heater but serves the same function in specific applications.

Understanding the Trade-offs

Choosing an element is an exercise in balancing performance requirements with physical and financial constraints. An element that excels in one area may have significant limitations in another.

Cost vs. Performance

There is a direct and unavoidable correlation between cost and maximum temperature.

Metallic wire elements are the most economical. SiC elements represent a significant step up in both cost and temperature capability. MoSi2 elements are the most expensive, reflecting their superior performance at extreme temperatures.

Atmosphere Compatibility

This is a critical, non-negotiable factor. Using the wrong element in the wrong atmosphere will lead to immediate failure.

SiC and MoSi2 are designed to thrive in oxidizing (air) atmospheres. Graphite, molybdenum, and tungsten are designed for vacuum or inert gas and will be destroyed by oxygen at high temperatures.

Element Lifespan and Fragility

Metallic wire elements are relatively ductile and resistant to mechanical shock.

Ceramic elements like SiC and MoSi2 are inherently brittle, especially at room temperature. They require careful handling during installation and maintenance to prevent breakage.

Making the Right Choice for Your Process

Your final decision must be grounded in the specific goals of your thermal process. Use the following guide to determine your best starting point.

- If your primary focus is on moderate temperature processes (below 1200°C): Metallic wire elements like FeCrAl or NiCr offer the best balance of cost and reliability.

- If your primary focus is on robust, high-temperature industrial processing in air (up to 1600°C): Silicon Carbide (SiC) elements are the established industry standard.

- If your primary focus is on achieving the highest possible temperatures in an air atmosphere (up to 1800°C): Molybdenum Disilicide (MoSi2) elements are the necessary choice, despite their higher cost.

- If your primary focus is on extreme temperature processing (>1800°C) in a vacuum or inert gas: Graphite or pure refractory metal elements are the only viable options.

Matching the heating element to your specific temperature and atmospheric needs is the key to efficient, reliable, and safe thermal processing.

Summary Table:

| Heating Element | Max Temperature | Atmosphere Compatibility | Key Features |

|---|---|---|---|

| Metallic Wire (FeCrAl/NiCr) | Up to 1200°C | Oxidizing | Cost-effective, durable, reliable for moderate heat |

| Silicon Carbide (SiC) | Up to 1600°C | Oxidizing | High power density, long life, ideal for calcining |

| Molybdenum Disilicide (MoSi2) | Up to 1800°C | Oxidizing | Premium choice, protective layer, extreme heat in air |

| Graphite | >2000°C | Vacuum/Inert | High-temperature, oxidizes in air, specialized use |

| Molybdenum/Tungsten | High (varies) | Vacuum/Inert | Refractory metals, oxygen-sensitive, for vacuum furnaces |

| Induction Coils | Varies | Various | Non-resistance heating, direct material heating |

Upgrade your lab's thermal processing with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how our tailored heating elements and furnaces can optimize your processes!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules