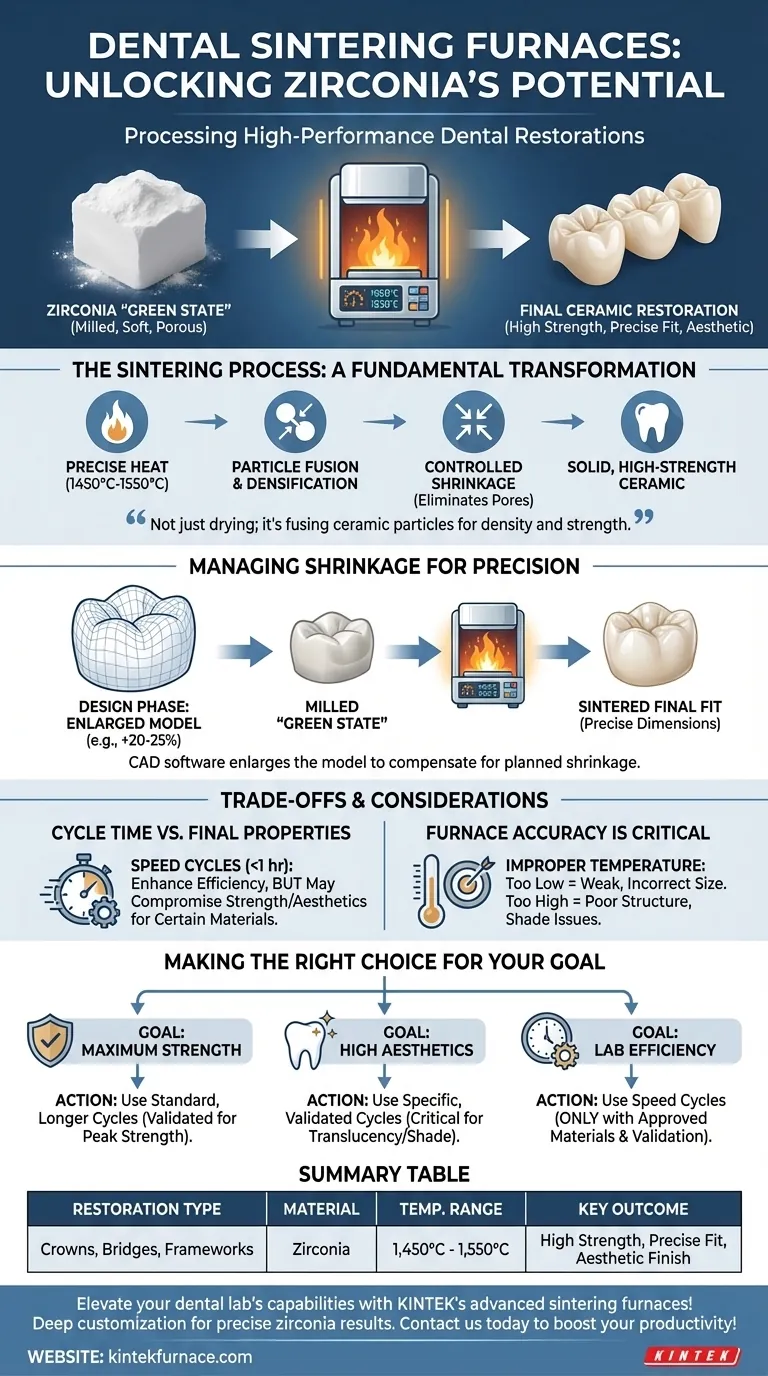

In short, dental sintering furnaces are used almost exclusively for processing restorations made from zirconia. After a zirconia crown, bridge, or framework is milled from a block, it exists in a soft, chalk-like state that must be heat-treated in a sintering furnace to achieve its final hardness, strength, and stable size.

Sintering is not merely a drying or hardening step; it is a fundamental transformation. The process uses precise heat to fuse ceramic particles together, densifying the material and causing it to shrink into a solid, high-strength restoration capable of withstanding oral forces.

The Role of Sintering in Restorative Dentistry

Dental restorations must endure immense functional forces from chewing. The materials used in modern CAD/CAM dentistry, particularly zirconia, are not in their final, durable state immediately after being shaped.

From "Chalk" to Ceramic

When a zirconia restoration is first milled, it is in a porous, pre-sintered condition often called the "green state" or "white state." In this phase, it is soft and chalky, making it easy to mill quickly and precisely.

However, this pre-sintered form is far too weak for clinical use. It would fracture immediately under normal biting pressure. The sintering furnace is what converts this fragile object into a final, high-performance ceramic.

The Sintering Process Explained

Sintering is a process of densification. The furnace heats the restoration to a very high temperature—typically between 1,450°C and 1,550°C—which is just below zirconia's melting point.

At this temperature, the individual zirconia particles fuse together at their contact points. This eliminates the pores between particles, causing the entire restoration to become denser and shrink significantly in size.

Managing Shrinkage: The Key to Precision

This shrinkage is not a defect; it is a planned and essential part of the process. The shrinkage factor for a given block of zirconia is known and is typically around 20-25%.

During the design phase, the CAD software automatically enlarges the restoration's digital model by this exact percentage. The oversized restoration is then milled, and upon sintering, it shrinks down to the precise dimensions required for a perfect fit.

Understanding the Trade-offs and Considerations

While sintering is a required step, the specific parameters of the process involve important trade-offs that every dental technician must manage.

Cycle Time vs. Final Properties

Manufacturers provide specific firing schedules for their materials. "Speed" or "fast" sintering cycles can dramatically reduce the processing time from many hours to under an hour.

However, these accelerated cycles can sometimes compromise the final outcome. For certain high-translucency zirconia materials, a rapid cycle might reduce the aesthetic value or final strength compared to a slower, conventional cycle.

Furnace Accuracy is Non-Negotiable

The success of a zirconia restoration is highly dependent on the accuracy of the sintering furnace. An improperly calibrated furnace that runs too hot or too cool can ruin the restoration.

If the temperature is too low, the zirconia will not fully sinter, resulting in poor strength and incorrect dimensions. If it's too high, it can affect the grain structure and shade, compromising both strength and aesthetics.

Making the Right Choice for Your Goal

The primary material processed in a dental sintering furnace is zirconia, but how you process it depends on your clinical or business objective.

- If your primary focus is maximum strength: Always adhere to the manufacturer's standard, longer sintering cycle, as this is what was used to validate the material's peak flexural strength data.

- If your primary focus is high aesthetics: Use the specific, validated cycle for the translucent zirconia you are working with, as its optical properties are highly sensitive to the heating and cooling protocol.

- If your primary focus is lab efficiency: You can use speed sintering cycles, but only with materials explicitly approved for such cycles and after validating that the results meet your quality standards for fit, strength, and shade.

Mastering the sintering process is fundamental to delivering predictable, durable, and aesthetic zirconia restorations.

Summary Table:

| Dental Restoration Type | Material Used | Sintering Temperature Range | Key Outcome |

|---|---|---|---|

| Crowns, Bridges, Frameworks | Zirconia | 1,450°C - 1,550°C | High strength, precise fit, aesthetic finish |

Elevate your dental lab's capabilities with KINTEK's advanced sintering furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures precise sintering for zirconia restorations, enhancing strength, aesthetics, and efficiency. Contact us today to discuss how our furnaces can meet your unique needs and boost your productivity!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations