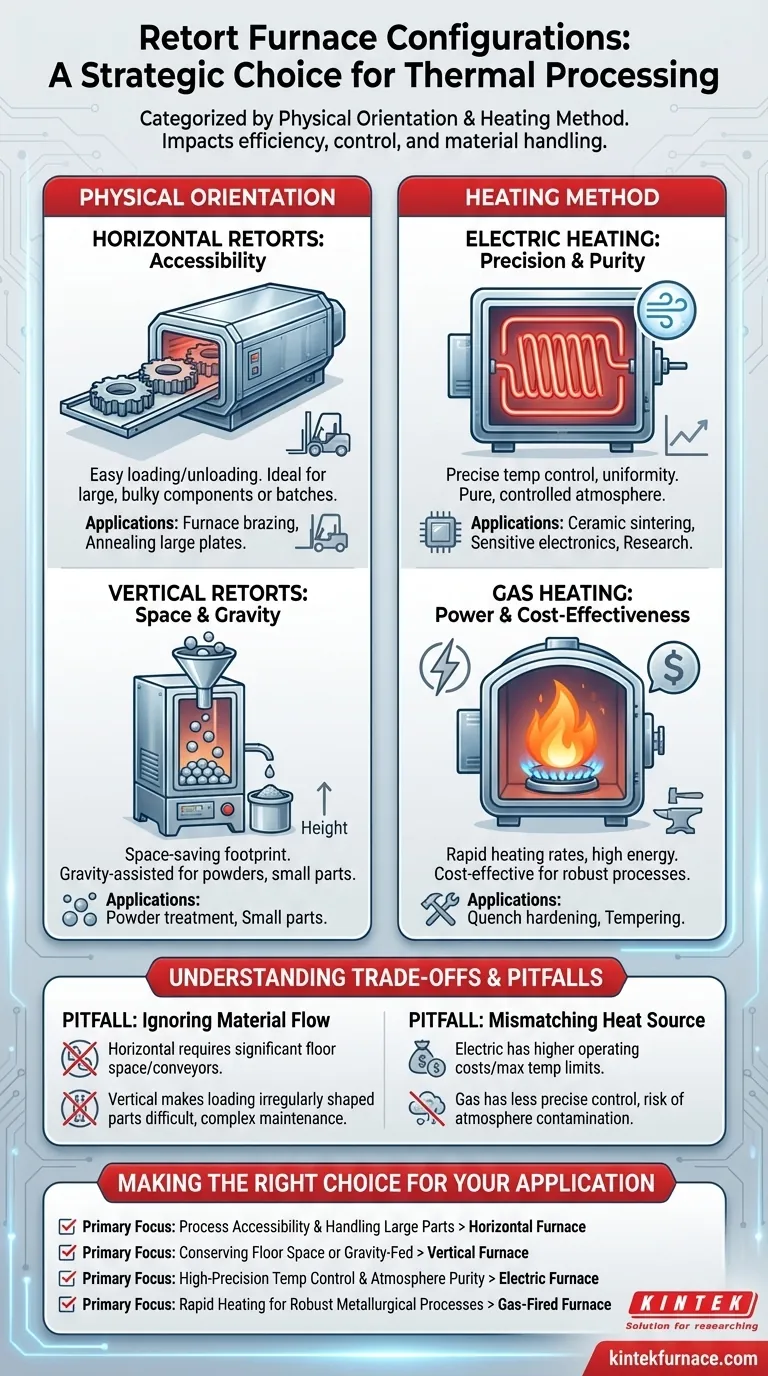

Fundamentally, retort furnaces are categorized by two primary physical orientations and two distinct heating methods. The physical layout is either horizontal or vertical, while the heating system is powered by either electricity or gas. These choices are not arbitrary; they are driven by the specific demands of the thermal process, facility constraints, and operational workflow.

Choosing the right retort furnace configuration is not just about fit; it's a strategic decision that directly impacts material handling, process control, and operational efficiency. The choice between horizontal vs. vertical and electric vs. gas heating dictates how you will interact with the furnace and the results you can achieve.

The Two Primary Physical Orientations

The physical layout of the furnace is the most visible configuration choice. It directly influences how material is loaded, processed, and unloaded, making it a critical decision based on your parts and your facility's floor space.

Horizontal Retorts: The Standard for Accessibility

Horizontal retort furnaces are the most common configuration, prized for their straightforward design. Their primary advantage is the ease of loading and unloading materials.

This layout is ideal for processing large, bulky components or batches of parts arranged on trays. Applications like furnace brazing of assemblies or annealing large metal plates are well-suited for a horizontal orientation.

Vertical Retorts: The Solution for Space and Gravity

Vertical retort furnaces are designed to solve two specific challenges: limited floor space and processes that benefit from gravity. By building up instead of out, they offer a much smaller footprint.

This design is ideal for facilities with height but limited floor area. Furthermore, vertical retorts excel in gravity-assisted processes, such as treating powders, small parts, or materials that can be dropped through the heat zone in a controlled manner.

The Critical Choice: Electric vs. Gas Heating

The method used to heat the retort is just as important as its orientation. This choice affects temperature precision, atmosphere purity, and operational cost.

Electric Heating: Precision and Atmosphere Purity

Electrically heated furnaces use resistance heating elements. Their defining benefit is exceptionally precise temperature control and uniformity, which is critical for sensitive materials.

Because there is no combustion, it is far simpler to maintain a pure, controlled atmosphere inside the retort. This makes electric heating the standard for processes like ceramic sintering, advanced material research, and treating sensitive electronics or alloys.

Gas Heating: Power and Cost-Effectiveness

Gas-fired furnaces use burners to generate heat. They are known for their ability to deliver high-energy input, allowing for rapid heating rates and high-temperature operation.

For large-scale, robust metallurgical processes such as quench hardening or tempering, gas heating can offer a more powerful and cost-effective solution, depending on local utility prices.

Understanding the Trade-offs

Every configuration involves compromises. Objectively evaluating these trade-offs is key to selecting the right furnace for long-term success.

Pitfall: Ignoring Material Flow

A horizontal furnace, while accessible, requires significant floor space and may necessitate conveyor systems or forklifts for heavy loads.

A vertical furnace saves floor space but can make loading irregularly shaped parts difficult. Maintenance access to components at the top or bottom can also be more complex.

Pitfall: Mismatching Heat Source to Process Needs

Electric furnaces may have higher operating costs in some regions and can be limited by the maximum temperature of their heating elements.

Gas furnaces offer less precise temperature control, and there is always a risk of atmosphere contamination from combustion byproducts if the retort integrity is compromised. This makes them less suitable for processes demanding absolute purity.

Making the Right Choice for Your Application

Your final decision must be guided by the primary goal of your thermal process.

- If your primary focus is process accessibility and handling large parts: A horizontal furnace is typically the most practical choice.

- If your primary focus is conserving floor space or using gravity-fed processes: A vertical furnace offers a superior solution, especially for powders and small components.

- If your primary focus is high-precision temperature control and atmosphere purity: An electrically heated furnace is the industry standard for sensitive applications like electronics and advanced ceramics.

- If your primary focus is rapid heating for robust metallurgical processes: A gas-fired furnace often provides the required power and cost-efficiency for hardening or tempering.

By aligning the furnace configuration with your specific operational needs, you ensure a more efficient, controllable, and effective thermal process.

Summary Table:

| Configuration Type | Key Features | Ideal Applications |

|---|---|---|

| Horizontal Orientation | Easy loading/unloading, large part handling | Furnace brazing, annealing of bulky components |

| Vertical Orientation | Space-saving, gravity-assisted processing | Powder treatment, small parts, limited floor space |

| Electric Heating | Precise temperature control, pure atmospheres | Ceramic sintering, sensitive electronics, material research |

| Gas Heating | Rapid heating, high power, cost-effective | Quench hardening, tempering, robust metallurgical processes |

Ready to enhance your lab's thermal processing with the perfect retort furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how we can optimize your setup for superior efficiency and results!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are some industrial applications of rotary tube furnaces? Boost Your Material Processing Efficiency

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating