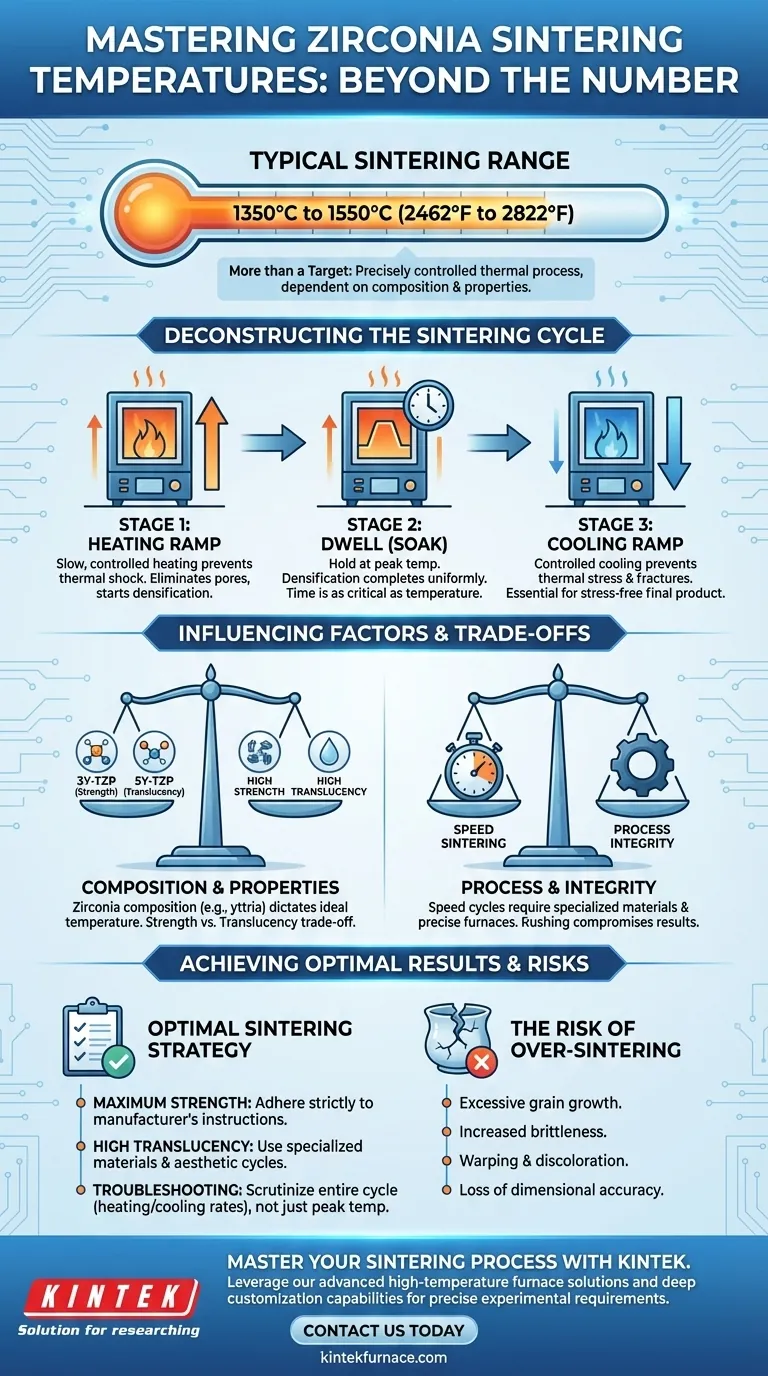

For most applications, zirconia ceramics are sintered within a temperature range of 1350°C to 1550°C (2462°F to 2822°F). However, this range is not a simple set-it-and-forget-it parameter. The precise temperature is dictated by the specific chemical composition of the zirconia and the final properties, such as strength and translucency, required for the component.

Sintering zirconia is not about hitting a single number. It is a precisely controlled thermal process where temperature, time, and material composition are interdependent variables that determine the final success and quality of the ceramic.

Why Temperature Is More Than a Target

The sintering temperature is the most critical factor in a process designed to transform a chalky, porous "green state" zirconia block into a dense, high-strength ceramic part. Understanding how temperature influences this transformation is key to achieving consistent results.

The Goal: From Powder to Solid

Sintering works by heating the material to a point where the individual ceramic particles begin to fuse. This process eliminates the pores between particles, causing the material to shrink significantly and increase in density. This densification is what gives the final part its exceptional strength.

How Temperature Governs Final Properties

The peak temperature directly influences the microstructure of the finished ceramic, primarily the grain size. A higher temperature or longer hold time generally leads to larger grain growth. This can affect the balance between strength and light transmission; for example, certain high-translucency dental zirconias rely on specific temperature profiles to achieve their aesthetic properties.

The Critical Role of Zirconia Composition

Zirconia used in technical applications is never pure; it is stabilized with other oxides, most commonly yttria (Y₂O₃). Materials like 3Y-TZP (3 mol% yttria-stabilized zirconia) are known for strength, while 5Y-TZP (5 mol% yttria) offers higher translucency. These different formulations have different ideal sintering temperatures. Always defer to the manufacturer's specific instructions for the material you are using.

Deconstructing the Sintering Cycle

A successful outcome depends on the entire thermal cycle, which consists of three distinct stages. A failure in any one stage can compromise the final part, regardless of the peak temperature.

Stage 1: The Heating Ramp

The furnace must heat the zirconia slowly and steadily. A controlled ramp rate, typically over several hours, prevents thermal shock. Heating too quickly can create internal stresses that lead to cracks before the part even reaches its peak temperature.

Stage 2: The Dwell (or Soak)

This is the phase where the furnace holds at the peak sintering temperature (e.g., 1500°C). The dwell time, which can range from two hours to longer, is just as critical as the temperature itself. It allows the densification process to complete uniformly throughout the part.

Stage 3: The Cooling Ramp

Cooling must also be carefully controlled. Rapid cooling reintroduces thermal stress into the newly densified, rigid structure, which is a primary cause of fractures and failures. A slow, programmed cooling ramp is essential for a stress-free final product.

Understanding the Trade-offs

Choosing a sintering profile often involves balancing competing properties. Understanding these trade-offs is the mark of an expert.

Strength vs. Translucency

In many dental zirconias, there is a trade-off between flexural strength and translucency. Sintering profiles designed for high translucency might use slightly different temperatures that can result in larger grain sizes, which may marginally reduce the absolute maximum strength compared to a high-strength profile.

Speed vs. Process Integrity

So-called "speed sintering" cycles dramatically reduce the total time in the furnace. While efficient, these cycles require furnaces capable of extremely precise control and zirconia materials specifically formulated for rapid heating and cooling. Attempting to rush a standard zirconia block can result in incomplete sintering, poor aesthetics, and compromised strength.

The Risk of Over-Sintering

Using a temperature that is too high is just as bad as one that is too low. Over-sintering leads to excessive grain growth, which can paradoxically make the ceramic more brittle. It can also cause warping, discoloration, and a loss of dimensional accuracy.

Achieving Optimal Sintering Results

To move from simply using a furnace to truly mastering the process, align your sintering strategy with your primary objective.

- If your primary focus is maximum strength (e.g., for posterior dental bridges or industrial parts): Adhere strictly to the manufacturer's recommended temperature for high-strength zirconia, avoiding the temptation to raise it.

- If your primary focus is high translucency (e.g., for aesthetic anterior crowns): Use a zirconia material specifically formulated for aesthetics and follow its unique sintering cycle, as it is designed to control grain growth for optimal light transmission.

- If you are troubleshooting a failed part (e.g., cracks or poor fit): Scrutinize your entire heating and cooling cycle rates, not just the peak temperature, as uncontrolled temperature changes are the most common cause of failure.

Ultimately, mastering zirconia sintering comes from treating it as a complete, integrated thermal process, not just a target temperature.

Summary Table:

| Aspect | Details |

|---|---|

| Typical Sintering Temperature Range | 1350°C to 1550°C (2462°F to 2822°F) |

| Key Influencing Factors | Zirconia composition (e.g., yttria content), required properties (strength vs. translucency) |

| Sintering Cycle Stages | Heating ramp, dwell (soak), cooling ramp |

| Common Trade-offs | Strength vs. translucency, speed vs. process integrity |

| Risks | Over-sintering (excessive grain growth, brittleness), thermal shock from improper ramps |

Master Your Zirconia Sintering Process with KINTEK

Are you aiming for maximum strength in industrial parts or high translucency in dental applications? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements.

Don't let inconsistent results hold you back—contact us today to discuss how our furnaces can optimize your sintering cycles, enhance material properties, and boost your lab's efficiency!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations