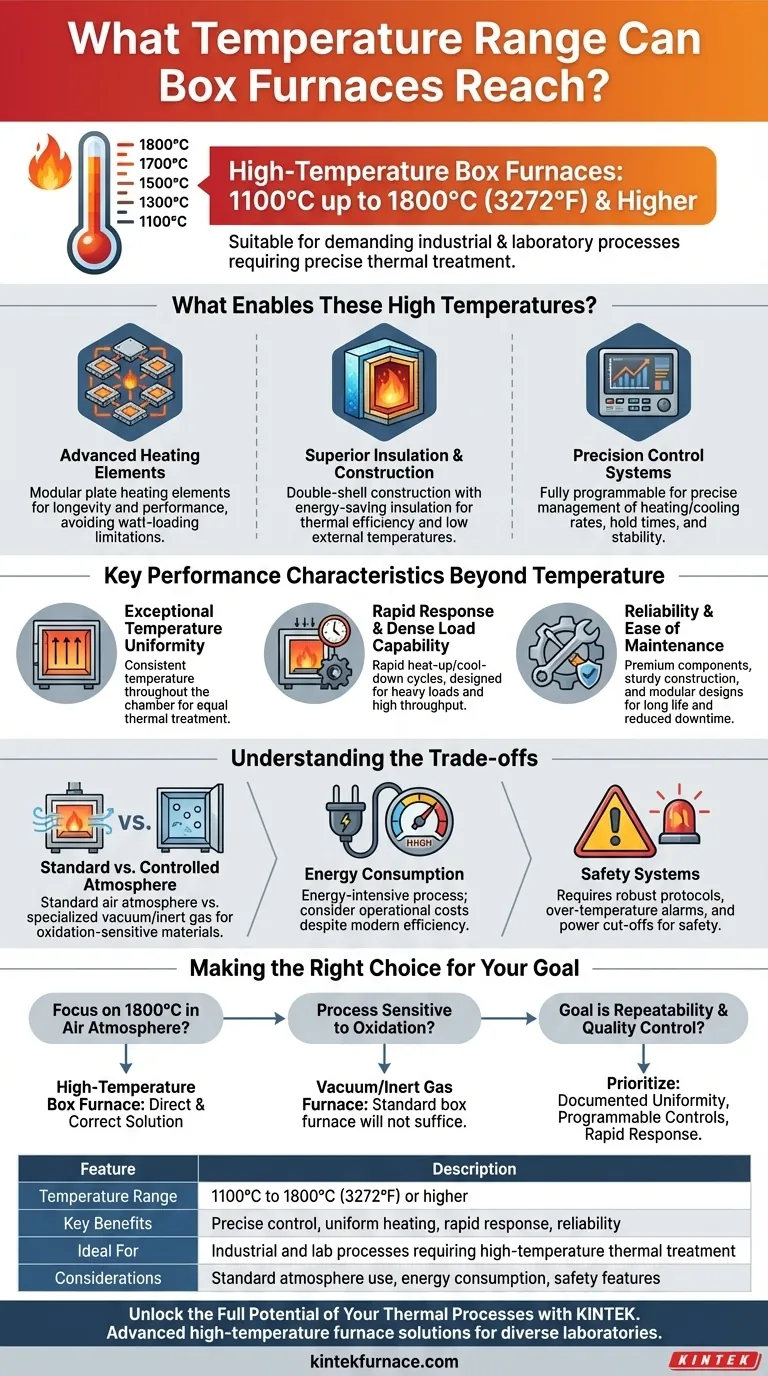

In short, high-temperature box furnaces are capable of reaching temperatures from 1100°C up to 1800°C (3272°F) and sometimes even higher. This wide operating range makes them suitable for a vast number of demanding industrial and laboratory processes that require precise thermal treatment.

While the maximum temperature is a critical specification, the true value of a modern box furnace lies in its ability to deliver that heat with exceptional uniformity, precision, and repeatability. The choice of furnace depends less on the peak temperature and more on the specific requirements of your process environment.

What Enables These High Temperatures?

A box furnace's ability to safely and reliably reach extreme temperatures is not accidental. It is the result of a deliberate system of interlocking design principles, where each component supports the others to create a stable, high-performance thermal environment.

Advanced Heating Elements

Modern furnaces often use modular plate heating elements. This design is known for its longevity and performance, as it avoids the normal watt-loading limitations that can cause premature failure in simpler heating element designs.

Superior Insulation and Construction

To contain such intense heat, these furnaces employ a double-shell construction paired with advanced, energy-saving insulation. This not only maximizes thermal efficiency and allows for rapid heat-up times but also keeps the external surface temperatures of the furnace remarkably low, enhancing operator safety.

Precision Control Systems

Reaching 1800°C is useless without the ability to control it. Box furnaces integrate fully programmable control systems. These allow for precise management of heating and cooling rates, hold times, and overall temperature stability, ensuring that processes are highly repeatable.

Key Performance Characteristics Beyond Temperature

The maximum temperature rating is only the headline. For any professional application, the following characteristics are often more critical for achieving desired outcomes.

Exceptional Temperature Uniformity

Advanced internal construction and airflow management ensure that the temperature is consistent throughout the entire chamber. This uniformity is vital for processes where every part of the load must receive the exact same thermal treatment.

Rapid Response and Dense Load Capability

These furnaces are engineered for performance under real-world conditions. They are designed for rapid heat-up and cool-down cycles and have the structural integrity to handle dense, heavy loads, maximizing throughput and efficiency in a production environment.

Reliability and Ease of Maintenance

Using premium components and sturdy construction contributes to a long operational life. Furthermore, features like modular heating elements are designed for easier maintenance, reducing downtime and the total cost of ownership.

Understanding the Trade-offs

No single piece of equipment is perfect for every task. Understanding the inherent limitations of a standard box furnace is key to making an informed decision.

Standard Atmosphere vs. Controlled Atmosphere

A standard box furnace operates with an air atmosphere. This is perfectly acceptable for many applications but will cause oxidation on susceptible materials. If your process requires an inert environment or a vacuum to prevent reactions like oxidation or decarburization, a specialized vacuum furnace is the appropriate tool.

Energy Consumption

Reaching and maintaining temperatures of 1700°C or 1800°C is an energy-intensive process. While modern designs are highly efficient, the absolute power consumption is a significant operational factor and cost that must be planned for.

Safety Systems

Operating at these temperatures demands robust safety protocols. High-quality furnaces include critical safety features like over-temperature alarms and power cut-offs. Ensure any considered model has these non-negotiable protections for both your personnel and facility.

Making the Right Choice for Your Goal

Select your equipment based on a clear understanding of your process requirements, not just the temperature specification.

- If your primary focus is reaching temperatures up to 1800°C in an air atmosphere: A high-temperature box furnace is the direct and correct solution for your needs.

- If your process is sensitive to oxidation: You must specify a vacuum furnace or one with inert gas capabilities, as a standard box furnace will not suffice.

- If your goal is process repeatability and quality control: Prioritize furnaces with documented temperature uniformity, programmable controls, and rapid response rates.

Ultimately, choosing the right furnace is about matching the equipment's capabilities to the precise demands of your application.

Summary Table:

| Feature | Description |

|---|---|

| Temperature Range | 1100°C to 1800°C (3272°F) or higher |

| Key Benefits | Precise control, uniform heating, rapid response, reliability |

| Ideal For | Industrial and lab processes requiring high-temperature thermal treatment |

| Considerations | Standard atmosphere use, energy consumption, safety features |

Unlock the Full Potential of Your Thermal Processes with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you need precise temperature control up to 1800°C, enhanced uniformity, or tailored solutions for your specific applications, we're here to help. Contact us today to discuss how our furnaces can boost your efficiency and reliability!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision