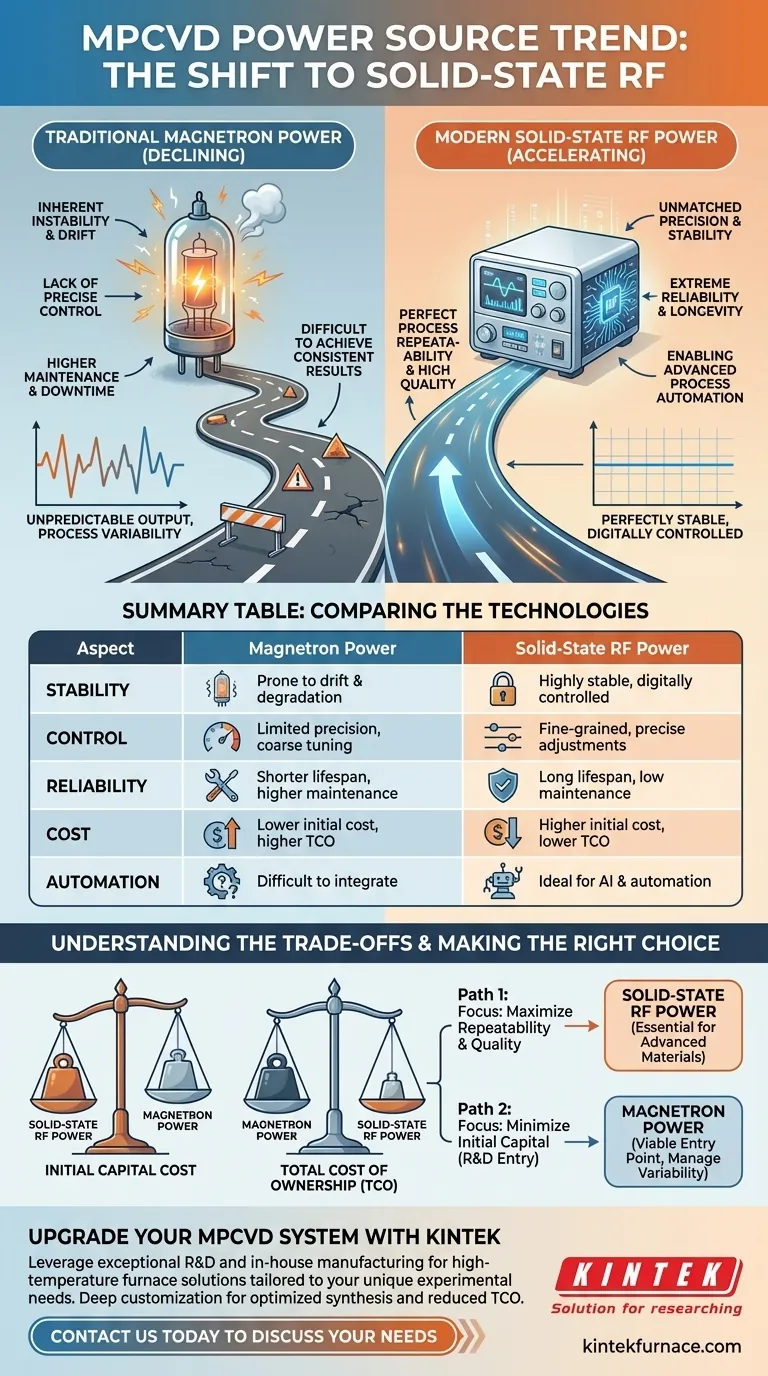

The most significant trend in Microwave Plasma Chemical Vapor Deposition (MPCVD) technology is the clear and accelerating shift away from traditional magnetron-based power sources. These are being systematically replaced by modern solid-state RF microwave power sources, a change driven by the demand for greater process control, reliability, and efficiency in advanced material synthesis.

This transition is more than a simple component upgrade; it represents a fundamental move towards precision engineering. By replacing the fluctuating nature of magnetrons with the absolute stability of solid-state electronics, operators unlock a new level of process repeatability and material quality.

The Limitations of Traditional Magnetron Power

For years, magnetrons were the standard for generating the microwave energy needed to create plasma in an MPCVD reactor. However, their inherent physical limitations present significant challenges for high-purity, high-volume production.

Inherent Instability and Drift

Magnetrons are essentially vacuum tubes that degrade over time. Their output power and frequency can drift during a single process run and will certainly change over the component's lifespan, introducing process variability.

This instability makes it difficult to achieve consistent results from one batch to the next, a critical failure for industrial-scale production.

Lack of Precise Control

A magnetron's power output is difficult to control with precision. They function more like a light switch with a very coarse dimmer, lacking the fine-grained tunability needed for optimizing complex recipes for materials like diamond or graphene.

This limitation restricts the ability to make micro-adjustments to the plasma, which are often necessary to achieve specific material properties.

Higher Maintenance and Downtime

Magnetrons are consumable components with a finite operational life. They require periodic replacement, which introduces system downtime, maintenance costs, and the risk of process inconsistencies each time a new unit is installed.

The Advantages of Solid-State RF Power

Solid-state generators are built on modern semiconductor technology, completely sidestepping the issues associated with vacuum tube-based magnetrons. They offer a level of control that is essential for next-generation material science.

Unmatched Precision and Stability

Solid-state power sources provide exact, digitally controlled power and frequency. This output remains perfectly stable throughout a process run and over the entire lifetime of the generator, which can exceed tens of thousands of hours.

This stability is the key to achieving perfect process repeatability and consistently high-quality material deposition.

Extreme Reliability and Longevity

Because they have no degrading filaments or consumable parts, solid-state microwave generators are exceptionally reliable. Their dramatically longer lifespan eliminates the downtime and replacement costs associated with magnetrons.

This reliability translates directly to a lower total cost of ownership (TCO) and higher system uptime.

Enabling Advanced Process Automation

The precise digital control of solid-state sources makes them ideal for integration with automation and AI systems. These systems can monitor the process in real-time and make millisecond adjustments to the power, enabling a level of optimization that is impossible with magnetrons.

This capability is a foundational requirement for developing more energy-efficient and intelligent MPCVD systems for nanomaterial synthesis.

Understanding the Trade-offs

While the benefits of solid-state technology are clear, it is important to consider the practical implications of adopting it.

Initial Capital Cost

Solid-state RF microwave power systems typically have a higher initial purchase price compared to their magnetron-based counterparts. This can be a significant factor for labs or companies with limited upfront capital.

Total Cost of Ownership (TCO)

The higher initial cost is often offset by a significantly lower TCO. Factoring in the lack of replacement parts, reduced maintenance, higher energy efficiency, and greater system uptime, the solid-state option frequently becomes the more economical choice over the long term.

Making the Right Choice for Your Goal

Your decision should align directly with your operational priorities and long-term goals.

- If your primary focus is maximizing process repeatability and producing high-quality material at scale: The superior stability and precise control of a solid-state RF power source are essential.

- If your primary focus is minimizing initial capital expenditure for exploratory R&D: A traditional magnetron system may be a viable entry point, but you must be prepared to manage process variability and eventual replacement costs.

Ultimately, adopting solid-state technology is an investment in the precision, reliability, and future-readiness of your material growth processes.

Summary Table:

| Aspect | Magnetron Power | Solid-State RF Power |

|---|---|---|

| Stability | Prone to drift and degradation | Highly stable, digitally controlled |

| Control | Limited precision, coarse tuning | Fine-grained, precise adjustments |

| Reliability | Shorter lifespan, higher maintenance | Long lifespan, low maintenance |

| Cost | Lower initial cost, higher TCO | Higher initial cost, lower TCO |

| Automation | Difficult to integrate | Ideal for AI and automation |

Ready to upgrade your MPCVD system with advanced solid-state RF power for unparalleled precision and reliability? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions like CVD/PECVD Systems, tailored to your unique experimental needs. Contact us today to discuss how our deep customization capabilities can optimize your material synthesis processes and reduce total cost of ownership!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment