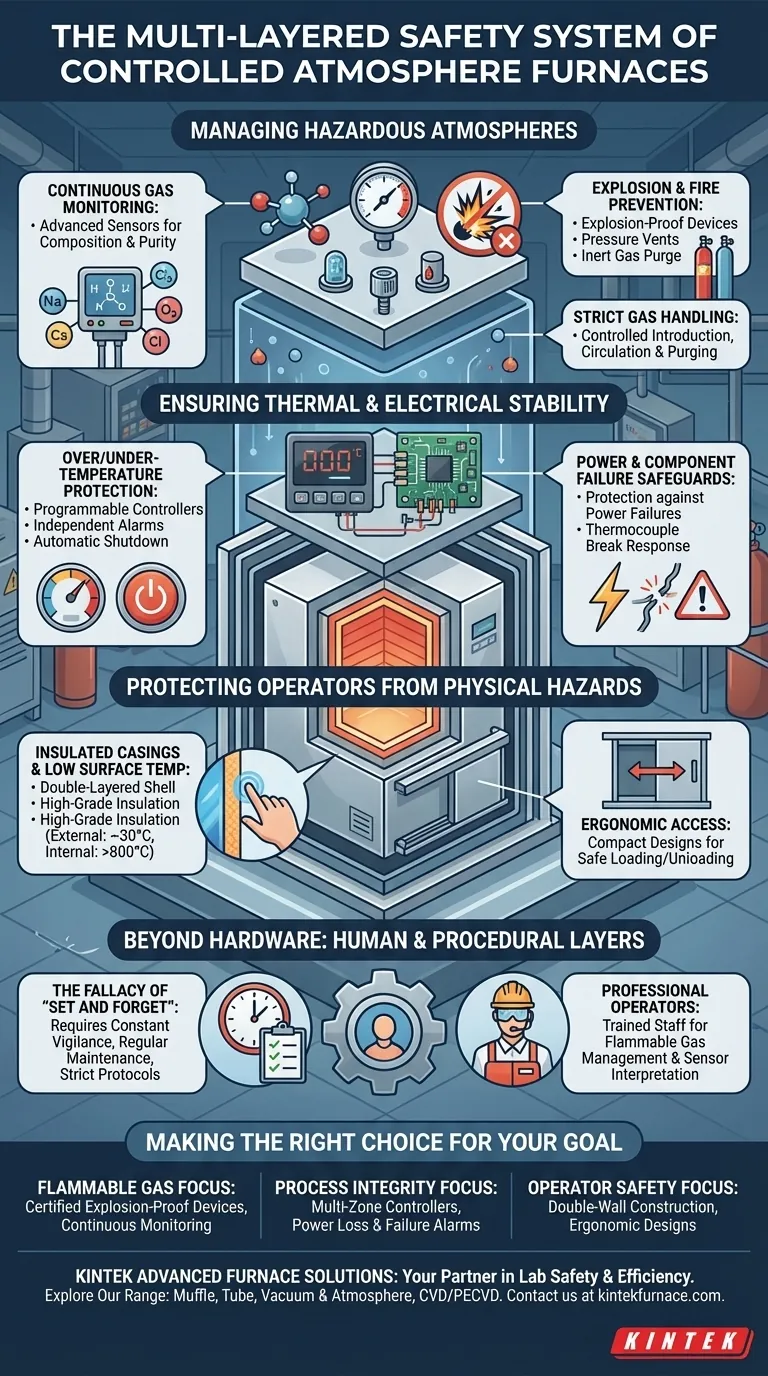

At their core, controlled atmosphere furnaces are equipped with a multi-layered system of safety mechanisms designed to manage their inherent risks. These include explosion protection devices for flammable gases, advanced sensor systems to monitor the atmosphere and temperature, and physical safeguards like insulated casings to protect operators from extreme heat.

The primary takeaway is that furnace safety is not achieved by a single feature, but through an integrated system. This system combines automated hardware controls, robust physical construction, and strict operational protocols to mitigate risks from hazardous gases, high temperatures, and potential equipment failure.

Managing Hazardous Atmospheres

The most significant risk in these furnaces comes from the specialized atmospheres they use. Safety systems are therefore focused on containing, monitoring, and controlling these gases.

Gas Monitoring and Control

Furnaces are equipped with advanced sensors to continuously monitor the atmospheric composition. This ensures the precise gas mixture is maintained for the process and, more critically, detects any dangerous leaks or deviations.

These systems also monitor for gas purity, as contaminants can compromise both the process and safety.

Explosion and Fire Prevention

For furnaces using flammable or explosive gases, dedicated explosion-proof devices are mandatory. These may include pressure relief vents or suppression systems.

In vacuum furnaces, safety is inherently enhanced by removing oxygen from the chamber, thereby eliminating the fuel required for a fire to start.

Strict gas handling systems and protocols ensure that gases are introduced, circulated, and purged from the furnace in a controlled and safe manner.

Ensuring Thermal and Electrical Stability

The combination of high temperatures and high power demands a robust set of safeguards against thermal runaway and electrical faults.

Over-Temperature and Under-Temperature Protection

Furnaces feature programmable digital controllers and independent alarm systems that protect against overheating and underheating.

If the temperature exceeds or falls below set safety limits, these systems will trigger an alarm and often initiate an automatic shutdown sequence to prevent damage to the equipment and the product.

Power and Component Failure Safeguards

Built-in protections guard against power failures and critical component failures, such as a thermocouple break.

A broken thermocouple is a serious risk, as the controller might otherwise apply continuous power, leading to a dangerous overheating event. The system is designed to detect this failure and respond safely.

Protecting Operators from Physical Hazards

Beyond the internal process, the furnace's physical design is critical for operator safety.

Insulated Casings and Low Surface Temperatures

Modern furnaces use a double-layered shell or double housing combined with high-grade insulation.

This design is exceptionally effective at containing heat, keeping the external surface temperature low—often around 29-30°C—even when internal temperatures reach 800°C or higher, thus preventing burns.

Ergonomic and Access Design

Features like a compact sliding tube design serve a dual purpose. They make loading and unloading materials easier and safer while also allowing for rapid cooling when necessary.

Beyond Hardware: The Human and Procedural Layers

Relying solely on automated safety features is a common and dangerous pitfall. The most robust safety system integrates technology with human expertise and procedure.

The Fallacy of "Set and Forget"

A controlled atmosphere furnace requires constant vigilance. Strict safety protocols and regular equipment maintenance are not optional—they are essential components of the overall safety framework.

Automated systems can fail, and only through routine checks and proper procedures can these potential failures be identified and mitigated before an incident occurs.

The Necessity of Professional Operators

Unlike simpler box furnaces, the complexity and potential hazards of atmosphere furnaces necessitate professional, trained operators.

Managing flammable gases, interpreting sensor data, and responding correctly to alarms requires a level of skill and understanding that is critical to safe operation.

Making the Right Choice for Your Goal

When specifying or operating a furnace, prioritize safety features that align with your specific process risks.

- If your primary focus is handling flammable gases: Insist on certified explosion-proof devices, continuous gas monitoring systems, and inert gas purge capabilities.

- If your primary focus is process integrity: Prioritize furnaces with precise, multi-zone temperature controllers and alarms for power loss and thermocouple failure.

- If your primary focus is operator safety and usability: Look for features like double-wall construction for low surface temperatures and ergonomic designs for safe loading.

Ultimately, a comprehensive approach that layers hardware, software, and rigorous procedures is the only way to ensure truly safe and reliable operation.

Summary Table:

| Safety Mechanism | Key Features |

|---|---|

| Gas Monitoring and Control | Advanced sensors for atmospheric composition and purity |

| Explosion and Fire Prevention | Explosion-proof devices, pressure relief vents, inert gas systems |

| Thermal and Electrical Protection | Over/under-temperature alarms, shutdown sequences, power failure safeguards |

| Physical Operator Safety | Insulated casings, low surface temperatures, ergonomic designs |

| Procedural and Human Factors | Strict protocols, regular maintenance, trained operators |

Ensure your lab's safety with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how our safety-focused designs can protect your operations and enhance efficiency!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process