To safely operate a dental sintering furnace, technicians must use personal protective equipment like heat-resistant gloves and safety goggles, strictly follow the manufacturer's operational protocols, and ensure the furnace has functioning safety features like automatic shut-off. Proper maintenance and allowing for adequate cooling time are also critical for preventing accidents and ensuring the quality of the restorations.

True operational safety extends beyond a simple checklist. It is a comprehensive system that combines proper user protocol, proactive equipment maintenance, and a deep understanding of the thermal risks inherent to the sintering process.

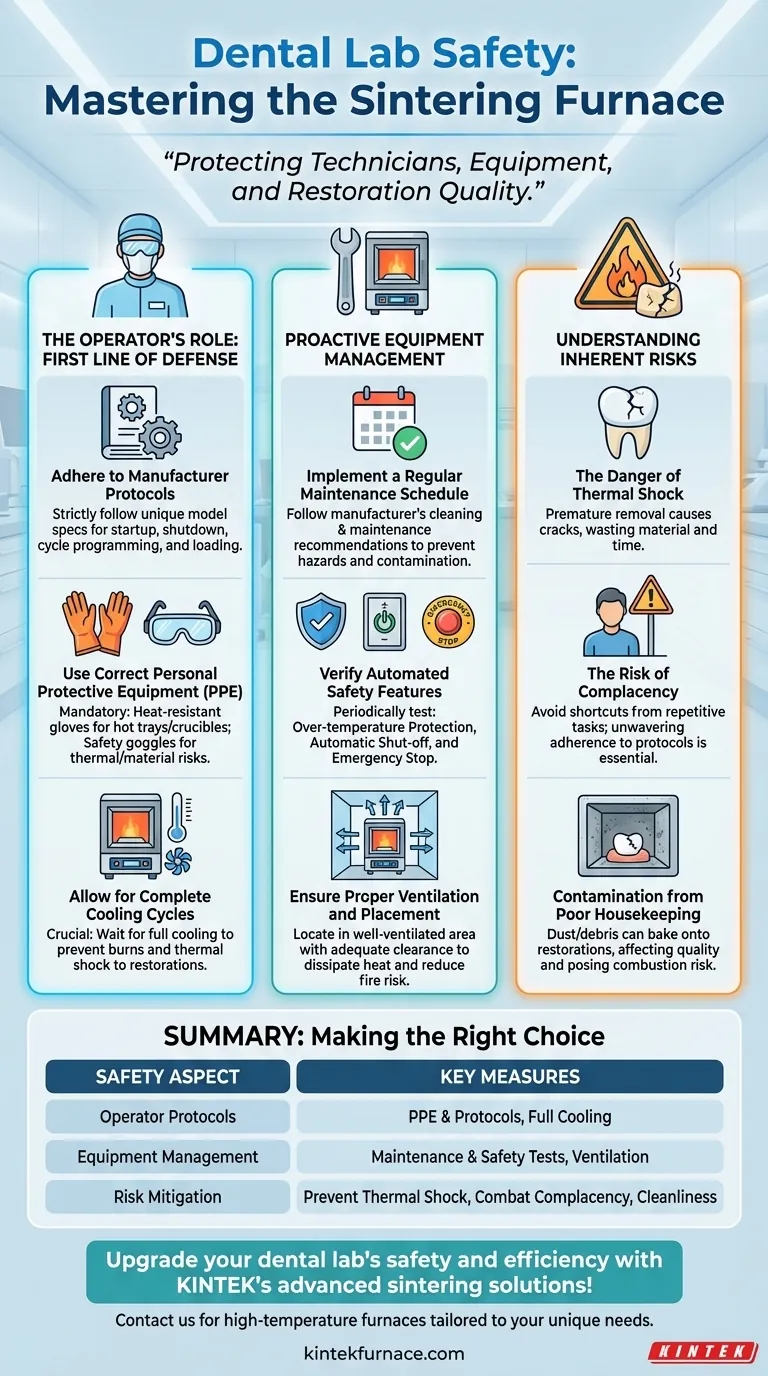

The Operator's Role: Your First Line of Defense

The most immediate safety measures are those controlled by the operator. These protocols are non-negotiable for protecting both the technician and the integrity of the dental restorations.

Adhere to Manufacturer Protocols

Every furnace model has unique specifications. The manufacturer's manual is the definitive guide for safe startup, shutdown, cycle programming, and loading procedures. Deviating from these instructions can lead to equipment damage or failed sintering.

Use Correct Personal Protective Equipment (PPE)

Sintering furnaces operate at extremely high temperatures. Heat-resistant gloves are mandatory when handling trays or crucibles, even if they appear cool. Safety goggles protect against potential thermal events or material fractures.

Allow for Complete Cooling Cycles

A major risk is removing restorations before the furnace has completed its full cooling cycle. Attempting to speed up this process not only creates a severe burn hazard but also risks thermal shock to the zirconia or other materials, causing fractures and compromising the final product.

Proactive Equipment Management

A safe furnace is a well-maintained furnace. Responsibility for safety extends to ensuring the equipment itself is in optimal working condition.

Implement a Regular Maintenance Schedule

Follow the manufacturer's recommendations for cleaning and maintenance. Regular cleaning prevents the accumulation of dust and debris, which can become a fire hazard or contaminate restorations.

Verify Automated Safety Features

Modern furnaces are equipped with critical safety systems. These should be tested periodically. Key features include:

- Over-temperature Protection: Prevents the furnace from exceeding its maximum safe temperature.

- Automatic Shut-off: Engages at the end of a cycle or in case of a malfunction.

- Emergency Stop: A manual button to immediately halt all operations in an emergency.

Ensure Proper Ventilation and Placement

The furnace should be located in a well-ventilated area to dissipate the significant heat it generates. Ensure there is adequate clearance around the unit as specified by the manufacturer to prevent heat buildup and reduce fire risk.

Understanding the Inherent Risks

Recognizing the potential points of failure is key to preventing them. Safety is not just about following rules, but understanding why those rules exist.

The Danger of Thermal Shock

The desire for efficiency can create a trade-off with safety and quality. Removing restorations from the furnace prematurely to save time can cause them to crack, wasting materials and requiring a complete redo of the work.

The Risk of Complacency

Using a sintering furnace is a daily, repetitive task in many labs. This repetition can lead to complacency, where operators may begin to take shortcuts, such as neglecting PPE for a "quick" task. A strict, unwavering adherence to safety protocols is essential every single time.

Contamination from Poor Housekeeping

Failing to keep the furnace chamber clean can directly impact the final product. Dust and other contaminants can bake onto the restoration surface, affecting its shade and structural integrity. In a worst-case scenario, this debris can pose a combustion risk.

Making the Right Choice for Your Lab

Your approach to safety should align with your lab's primary goals, creating a culture where safe practices are second nature.

- If your primary focus is personnel safety: Prioritize consistent use of PPE and strict adherence to cooling protocols to prevent burns and other injuries.

- If your primary focus is equipment longevity: Commit to a documented maintenance schedule and regular verification of the furnace's automated safety systems.

- If your primary focus is consistent restoration quality: Enforce protocols for furnace cleanliness and complete cooling cycles to prevent material contamination and thermal shock fractures.

Ultimately, a safe lab is an efficient and reliable one, where every team member understands their role in protecting themselves, the equipment, and the final product.

Summary Table:

| Safety Aspect | Key Measures |

|---|---|

| Operator Protocols | Use heat-resistant gloves and safety goggles; follow manufacturer instructions; allow full cooling cycles |

| Equipment Management | Regular cleaning and maintenance; verify over-temperature protection and automatic shut-off; ensure proper ventilation |

| Risk Mitigation | Prevent thermal shock by avoiding premature removal; avoid complacency; maintain cleanliness to prevent contamination |

Upgrade your dental lab's safety and efficiency with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces tailored for dental labs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Ensure reliable, high-quality restorations while minimizing risks—contact us today to discuss how we can support your lab's goals!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time