A modern muffle furnace integrates multiple safety systems designed to protect the operator, the equipment, and the sample being processed. Key features include over-temperature protection to prevent thermal runaway, physical insulation to shield users from extreme heat, and mechanisms to control or vent potentially hazardous gases created during heating.

Muffle furnace safety is not a single feature, but an integrated system. It combines robust thermal management, failsafe electrical safeguards, and precise atmospheric controls to create a predictable and secure high-temperature environment.

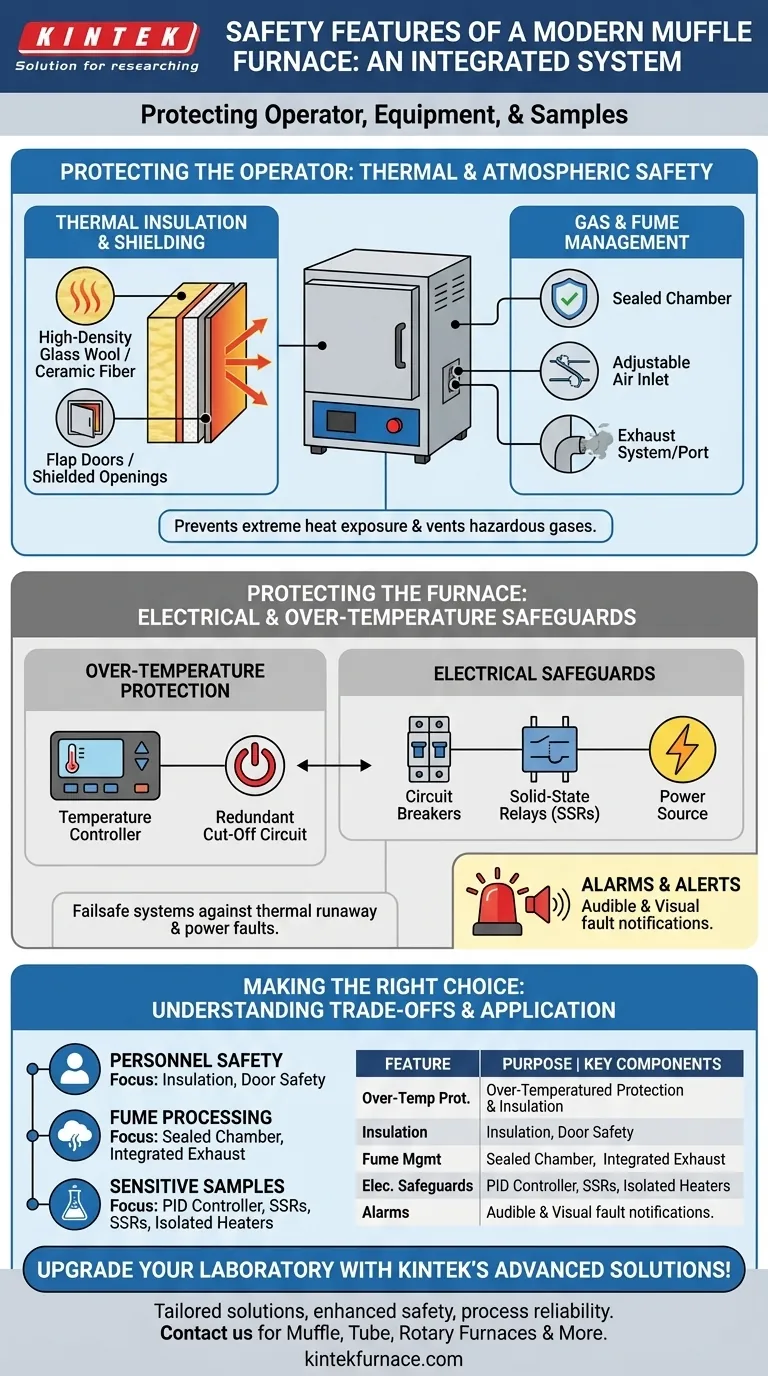

Protecting the Operator: Thermal and Atmospheric Safety

The most immediate risks in operating a muffle furnace are exposure to extreme heat and hazardous fumes. Safety features are specifically designed to mitigate these dangers.

Thermal Insulation and Shielding

A primary safety function is preventing the furnace's high internal temperatures from reaching the operator. This is achieved through multi-layered insulation.

Materials like high-density glass wool or ceramic fiber blankets are used within the furnace walls. These materials provide excellent thermal efficiency, keeping the outer surfaces of the unit at a safe temperature.

Additional features like flap doors or shielded openings protect users from direct heat radiation when accessing the chamber.

Gas and Fume Management

Heating certain materials can release aggressive or toxic gases. A controlled atmosphere is critical for both operator safety and sample integrity.

Many furnaces feature a sealed muffle chamber with an exhaust system or port. This allows harmful byproducts to be safely vented out of the laboratory.

Adjustable air inlets can also help manage the internal atmosphere and direct the flow of gases away from the operator.

Protecting the Furnace: Electrical and Over-Temperature Safeguards

To ensure longevity and prevent catastrophic failure, a furnace must be able to protect itself from electrical faults and thermal runaway.

Over-Temperature Protection

This is arguably the most critical safety mechanism. It is a redundant system that acts as a failsafe if the primary temperature controller fails.

If the furnace exceeds a preset maximum temperature, the over-temperature protection circuit will automatically cut power to the heating elements, preventing damage to the furnace and its contents.

Electrical Circuit Integrity

Like any high-power device, a muffle furnace is equipped with electrical circuit breakers. These protect the internal components from damage caused by power surges or short circuits.

The use of Solid-State Relays (SSRs) to manage the heating elements also contributes to safety. SSRs offer more precise and reliable power switching than mechanical relays, reducing the risk of failure.

Alarms and Alerts

Most digital furnaces include audible and visual alarms. These systems alert the operator to fault conditions, such as an over-temperature event or sensor failure, allowing for prompt intervention.

Understanding the Trade-offs

While safety is paramount, not all features are standard across all models. Understanding the distinctions is key to making an informed choice.

Standard vs. Optional Features

Basic furnaces will always include insulation and primary temperature control. However, advanced features like integrated exhaust systems, over-temperature protection, and sophisticated alarms may be standard on high-end models but optional add-ons for entry-level units.

The Role of Process Control in Safety

Features often marketed for performance, like PID (Proportional-Integral-Derivative) controllers, are also safety features. By ensuring highly accurate and stable temperatures, they prevent the temperature fluctuations and overshoots that can create hazardous conditions.

User Responsibility is Non-Negotiable

No safety feature can replace proper training and procedure. Understanding the materials you are heating and following established safety protocols for your lab are just as critical as the furnace's built-in protections. The furnace is a tool; the operator is the first line of defense.

Making the Right Choice for Your Application

Select a furnace with safety features that align directly with your primary use case.

- If your primary focus is personnel safety in a multi-user lab: Prioritize furnaces with robust insulation, door safety switches, and comprehensive over-temperature protection and alarm systems.

- If your primary focus is processing materials that release fumes: Insist on a model with a sealed chamber and an integrated exhaust port for safe venting.

- If your primary focus is protecting valuable or sensitive samples: Choose a furnace with a precise PID controller, SSR-based heaters, and isolated heating elements to prevent contamination and thermal shock.

Ultimately, a thorough understanding of these integrated safety systems empowers you to select and operate equipment with confidence and security.

Summary Table:

| Safety Feature | Purpose | Key Components |

|---|---|---|

| Over-Temperature Protection | Prevents thermal runaway and damage | Redundant circuits, power cut-off |

| Thermal Insulation | Shields operators from extreme heat | Glass wool, ceramic fiber, flap doors |

| Gas and Fume Management | Vents hazardous byproducts safely | Sealed chamber, exhaust ports, air inlets |

| Electrical Safeguards | Protects against power faults | Circuit breakers, solid-state relays (SSRs) |

| Alarms and Alerts | Notifies of fault conditions | Audible and visual alarms |

Upgrade your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, enhancing operator protection and process reliability. Contact us today to discuss how our furnaces can safeguard your operations and deliver superior performance!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation