In short, modern dental lab furnaces are equipped with a layered system of safety features designed to prevent overheating, protect operators from high temperatures, and manage electrical and environmental hazards. Key mechanisms include automatic over-temperature shut-offs, safety interlocks that cut power when the door is opened, advanced thermal insulation, and alarms for system malfunctions.

The safety of a dental furnace is not defined by a single feature, but by an integrated system of active and passive controls. Understanding how these systems work together is essential for protecting your personnel, your investment, and the integrity of your dental restorations.

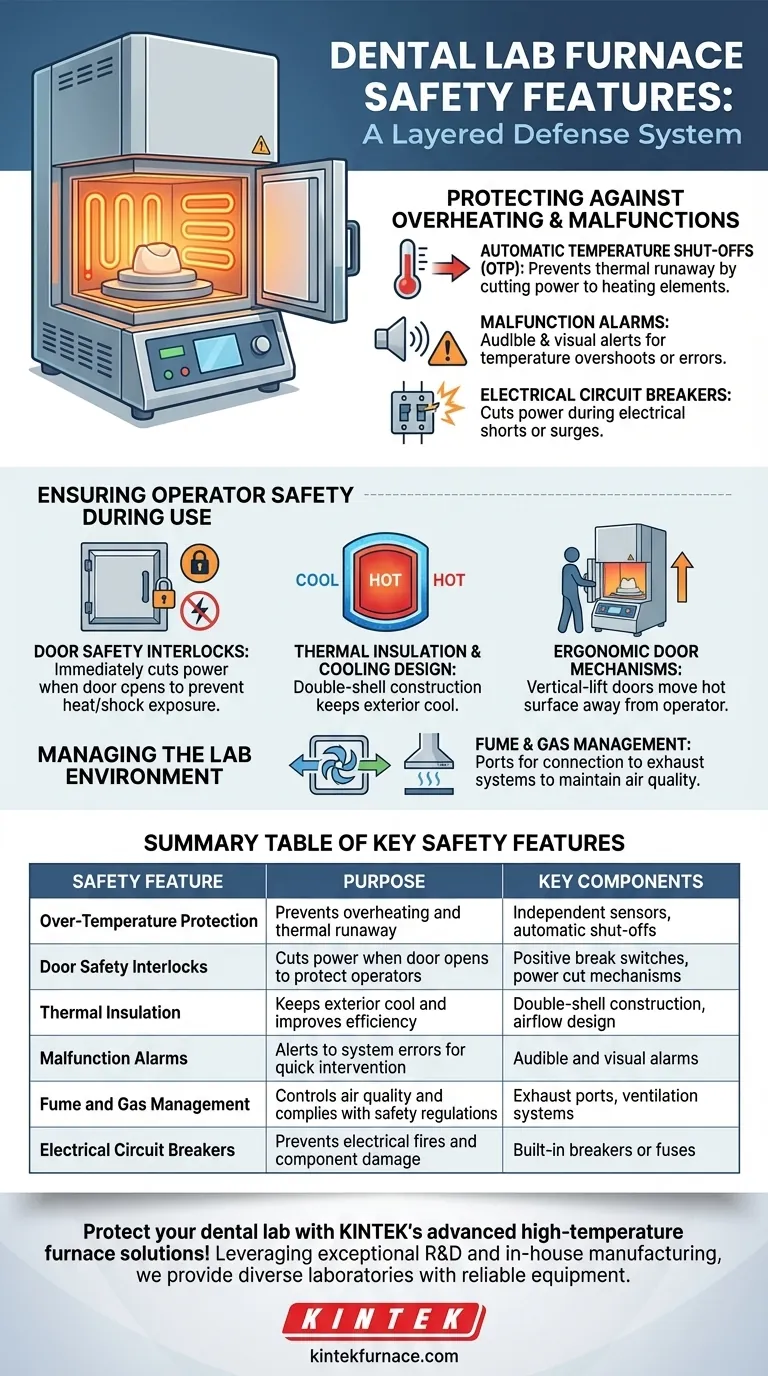

Protecting Against Overheating and Malfunctions

The most fundamental risk in any furnace is excessive heat. Modern equipment employs several redundant systems to prevent thermal runaway and alert users to potential failures.

Automatic Temperature Shut-offs

This is your primary defense against a catastrophic failure. An independent controller or sensor monitors the chamber temperature, and if it exceeds a pre-set maximum safe limit, it automatically cuts power to the heating elements.

This system, often called Over-Temperature Protection (OTP), acts as a critical fail-safe, protecting both the furnace itself and the valuable zirconia or ceramic work inside.

Malfunction Alarms

Furnaces are equipped with audible and visual alarms to notify technicians of any deviation from normal operation. This can include temperature overshoots, heating element failure, or other system errors.

These alarms provide an immediate alert, allowing for quick intervention before a minor issue becomes a major problem.

Electrical Circuit Breakers

Beyond temperature control, furnaces have built-in circuit breakers or fuses. In the event of an electrical short or power surge, these devices will instantly cut all power to the machine.

This feature is crucial for preventing electrical fires and protecting the unit's sensitive electronic components from damage.

Ensuring Operator Safety During Use

Protecting the technician from extreme heat and high voltage is a paramount design consideration, addressed through both mechanical and material engineering.

Door Safety Interlocks

Nearly all modern furnaces feature a safety interlock switch connected to the door. When the door is opened, this switch immediately cuts power to the heating elements.

This simple but effective mechanism prevents operator exposure to the chamber's intense radiant heat and eliminates any risk of electrical shock from the active heating elements. Some designs use a positive break safety switch for an even higher degree of reliability.

Thermal Insulation and Cooling Design

Furnaces use advanced insulating materials and often employ a double-shell construction. This design allows for airflow between an inner and outer casing, keeping the exterior surfaces cool to the touch.

This minimizes the risk of accidental burns and also improves the furnace's energy efficiency by preventing heat loss into the lab environment.

Ergonomic Door Mechanisms

Thoughtful design also plays a role in safety. Many box furnaces use vertical-lift doors, which move the hot interior face of the door up and away from the operator when opened.

This design is inherently safer than a swing-out door, where the hot surface swings directly toward the person operating it.

Managing the Lab Environment

A furnace's impact isn't confined to its own chassis. Safety features must also account for the air quality and conditions of the surrounding laboratory.

Fume and Gas Management

Certain dental materials can release fumes or gases during the sintering or burnout process. High-end furnaces may be equipped with ports for connection to a fume hood or local exhaust system.

Proper ventilation is essential for maintaining a safe breathing environment and complying with occupational safety regulations.

Understanding the Trade-offs

While modern features provide a robust safety net, it's critical to understand their limitations and the role of lab procedure.

Feature Reliability is Not a Guarantee

Safety systems like sensors and interlocks are components that can fail. Relying on them blindly without a program of regular inspection and maintenance is a significant risk.

Automated safety features augment, but do not replace, the need for vigilant operators and a consistent equipment maintenance schedule.

The Human Factor: The Role of Training

The most advanced safety system in the world can be rendered useless by an untrained operator. Technicians must understand what each alarm means, why they should never bypass a door interlock, and how to respond in an emergency.

Safety is ultimately a partnership between the machine's design and the user's knowledge.

How to Make the Right Choice for Your Goal

Selecting a furnace requires matching its safety profile to the specific needs of your lab.

- If your primary focus is basic, reliable operation for zirconia: Prioritize furnaces with proven Over-Temperature Protection and a reliable door safety interlock as your core requirements.

- If you work with diverse materials or perform burnouts: Insist on a furnace with integrated ventilation capabilities or an easy connection to an exhaust system to manage fumes.

- If you operate a high-volume production lab: Invest in a model with comprehensive alarms and data logging to ensure process consistency and provide early warnings of component wear or failure.

By understanding these integrated safety systems, you can make an informed decision that protects your staff and ensures the long-term reliability of your operations.

Summary Table:

| Safety Feature | Purpose | Key Components |

|---|---|---|

| Over-Temperature Protection | Prevents overheating and thermal runaway | Independent sensors, automatic shut-offs |

| Door Safety Interlocks | Cuts power when door opens to protect operators | Positive break switches, power cut mechanisms |

| Thermal Insulation | Keeps exterior cool and improves efficiency | Double-shell construction, airflow design |

| Malfunction Alarms | Alerts to system errors for quick intervention | Audible and visual alarms |

| Fume and Gas Management | Controls air quality and complies with safety regulations | Exhaust ports, ventilation systems |

| Electrical Circuit Breakers | Prevents electrical fires and component damage | Built-in breakers or fuses |

Protect your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise safety features tailored to your unique experimental needs, enhancing operator protection and process integrity. Contact us today to discuss how our furnaces can elevate your lab's safety and efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations